|

B

arry's

T

ire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

DOT Testing: The Department of Transportation (DOT) is the US governmental agency that regulates all forms of transportation in the US.

That includes air travel (FAA), rail travel, travel on water, and what we are interested in, roads (through the National Highway

and Traffic Safety Administration - NHTSA - pronounced Nit-Sah). As part of that, NHTSA also regulates car and truck related equipment, such as tires and child car seats. I am only

going to talk about passenger car and light truck tires, but there are also regulations and tests covering trailers, trucks, motorcycles

- anything that operates on the nation's highways. In order to sell tires in the US, the tires have to pass a series of tests - commonly called the DOT tests. If a tire has the letters "DOT", it is considered

to adhere to all the regulations. Usually, the letters appear in front of the TIN (Tire Identification Number), commonly called the DOT number or serial number,

but the letters only have to be in the vicinity of the TIN. Please note that this testing is conducted by the tire manufacturer (self certification)

just like much of the other testing required by the government. Also please note that the letters "DOT" are only a US government

requirement, but much of the world accepts this as sufficient testing for their country. I don't know if any other government specifies those letters. |

|

FMVSS 139: The Federal Motor Vehicle Safety Standards (FMVSS) is a series of regulations concerning automobiles, trucks, and motorcycles, the first of which came into effect in 1967. The regulations also include ancillary components, such as tires, baby seats, bike racks, and motorcycle helmets - among many others. The current regulation that covers tires for passenger cars and light duty trucks (less than 10,000# GVW) is FMVSS 139. That means it covers P type, LT type, and C type tires. Other kinds of tires are covered in other sections. (For example: ST tires are covered by FMVSS 119.) |

|

There are a number of things NOT covered by FMVSS 139:

|

|

|

|

|

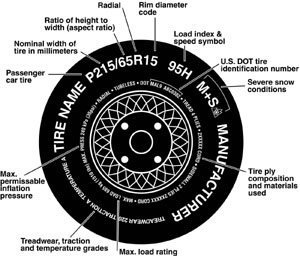

HOWEVER, FMVSS 139 does stipulate what is required to be on the sidewall and what it looks like - like the size of the letters, where on the sidewall they appear, etc. Also, treadwear indicators are specified - both shape, location, and size - 2/32nds of an inch (1.6mm). Please note that the regulation doesn't say anything about this being the legal minimum. It is state regulations that declare what the legal minimums are, and many states do not have any regulation for this. |

|

|

There is a quirk in the regulations I want to point out: The regulations call for the tire to display the max load and inflation pressure. It is stated that way. Some interpret that to mean the Max load and the Max inflation pressure. Usually this is stated "Max Load XXXX, Max Pressure YY". Others interpret that to mean the Max load and its corresponding pressure - like this: "Max Load XXXX at YY pressure". Clearly those are two different things. Then there is the third group who seem to be confused by this and state: "Max Load XXXX at Max Pressure YY". (Emphasis mine.) This is just misleading and confusing to the consumer. But the differences in the way these things are stated (see above) does not mean the published relationship between load carrying capacity and inflation pressure has changed. I wish NHTSA would make this clearer. The third way is particularly misleading and the average consumer doesn't understand why the relationship is different than what is printed on the sidewall. |

|

Bead Unseating Test: To the left is a tire being tested for bead unseating. Notice the peculiarly shaped silver "mandrel". There is a minimum force value, based on tire size/type. The purpose of this test is to assure that tires stay on the rim when cornering at reasonable levels. This may have been a problem when the regulations were first implemented (1967), but I know of no issues since that time. In some respects this test is obsolete. HOWEVER, there are some new severe handling tests where the bead becomes unseated during testing. This wasn't the case many years ago, but as tire grip improved, this is more common. In order to safely conduct the test, it is common for innertubes to be installed. Keeping in mind that these new tests are severe, I'm not sure how I feel about all this - both the unseating and the tubes. |

|

Tire Strength Test: In the industry, this is usually called "Plunger-Energy". Obviously this test is used to measure the amount of energy needed for a blunt object to penetrate a tire's tread. There is a minimum energy value. This is usually stated in Joules - a unit of energy - but it can also be stated as force times distance (inch-pounds or newton-meters). This varies by size. The test is supposed to be run multiple times on a single tire. It is common for the test to be conducted up to some value slightly larger than the minimum, then stopped before the tire fails. This is so that the tire doesn't lose its air retaining properties during the test. EXCEPT for the last run, where the test is run to obtain the maximum value. This usually results in the tire being ruptured - although sometimes the tread bottoms out against the rim. As a tire design engineer, it became obvious that it would be better to have a flexible tire, rather than a strong, but stiff tire. |

|

|

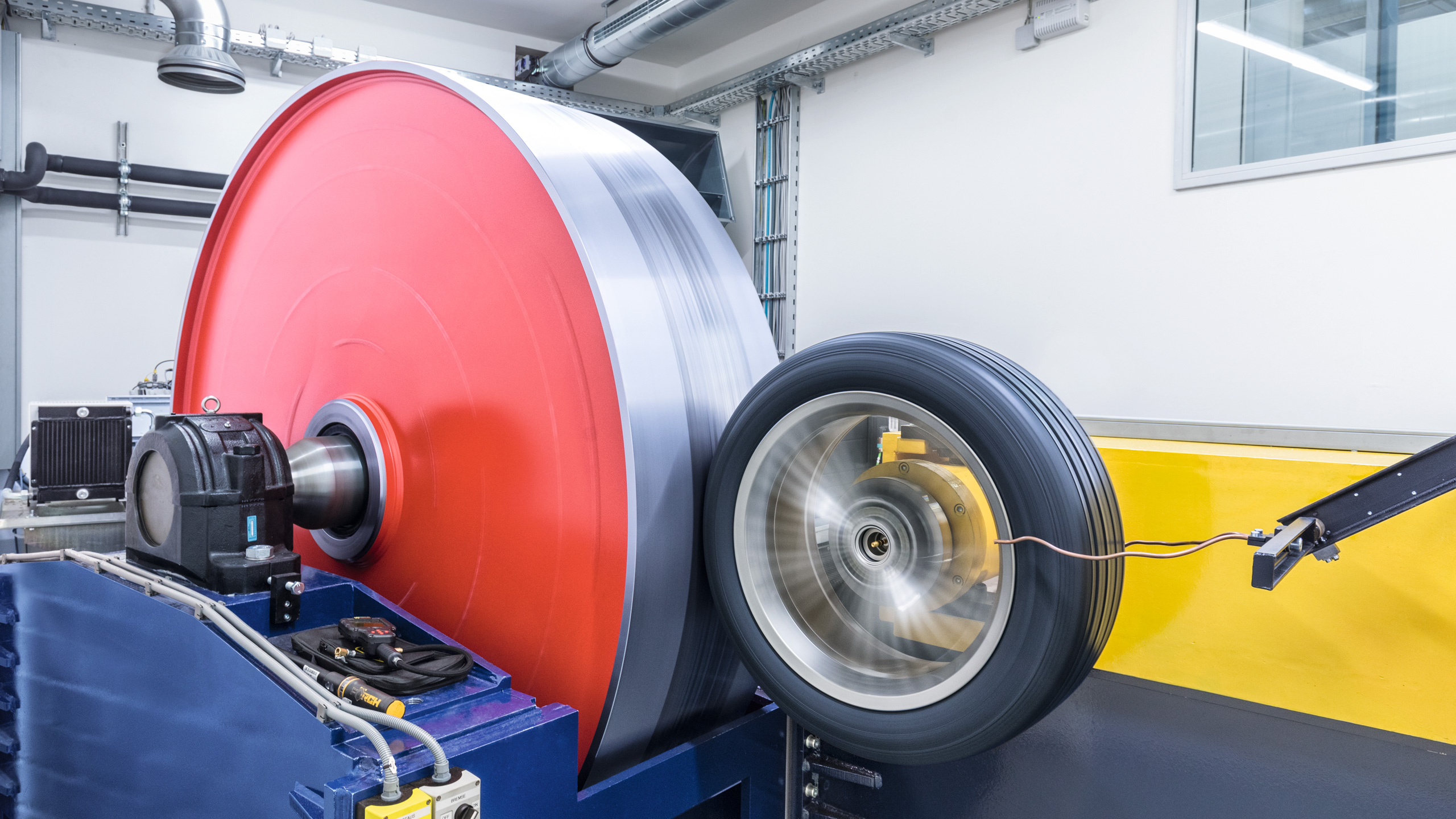

Tire Endurance Test: Of all the tests, this one is of the most interest to tire engineers. This is commonly referred to as "Step Load" or "Step Up Load" Test. The test is run on an industry standard testing machine, known as a "pulley wheel". An example is shown to the left. The test is run in a 38°C (100°F) room at 120 kph (75 mph) for normal tires and 110 kph (68 mph) for tires with the Alpine (3PMSF) symbol. The test is run at a reduced pressure compared to the load table. The pressure varies according to the type of tire, but one way to look at it is that the result is the tire is about 25% overloaded at the end of the test (100% rated load). |

|

The tire is run for 4 hours at 85% of the rated load. The load is increased to 90% of the rated load and run for 6 hours. The last step is increasing the load to 100% (effectively 25% overloaded because of the lower than rated inflation pressure) and run for 24 hours. The test is stopped and the tire is inspected. If there are no failures, the tire passes the test. Summarizing, the test is run for 34 hours, finishing up at 100% rated load, but about 25% overloaded for the pressure specified. BUT It doesn't stop there. The same tire is used in the .......... |

|

|

Low Inflation Performance Test: As stated above, the same tire is used after it completes the Endurance test. The tire is allowed to cool for at least 2 hours in the test room (at 38°C = 100°F). The test is run with reduced inflation pressure. It varies according to the type of tire, but the net effect is that the tire is about 50% overloaded. The speeds are the same as the Endurance test (120 kph = 75 mph for normal tires and 110 kph = 68 mph for Alpine (3PMSF) tires). The test is run for 90 minutes at 100% of the rated load. (Effectively overloaded at 150%.) The tire is inspected and if it hasn't failed, it passes. |

|

High Speed Performance Test: This test is run at an inflation pressure dependent on the type of tire. The net effect is that the tire is about 88% loaded during the test. The test starts with a break-in cycle of 80 kph (50 mph) for 2 hours, followed by a 2 hour cool-down cycle where the tire is completely unloaded. Then the real test starts:

The tire passes if it shows no signs of failure. |

|

|

Some interesting side notes: Because the first version of the Endurance test (1967) was similar to an industry standard test, it was common for tire manufacturers to use a version that extended the test, so that the tire would eventually fail. That way, not only would there be data to establish that the manufacturer was complying with the regulations, there was also a HUGE!! amount of data for statistical purposes. One way to extend the test was to add steps AFTER the end of the DOT test. A common one before the test was changed in 2002 was 2 hour steps (at 50 mph = 100 miles), with each step being a 5% increase in load over the previous step - until failure. However, the Endurance Test was changed in 2002 and I don't know what changes were made to this extended test, but I kept hearing about results from the "Step Load Test", so some version was carried over. |

|

It was also common for there to be "Quality Compliance Tests" run where the test was run in those same steps above, but only up to some load value considered to be large enough that there would be no argument that all tires produced would 100% pass the DOT test.

|

|

|

DOT Compliance Testing: Having a regulation and not enforcing it is just plain stupid. (OK, this might be interpreted as me criticizing the US government, and I totally am! But stupidity is not confined to the US borders.) NHTSA does test samples of tires bought on the open market to assure that the regulations are being met. Since all of the above tests are lab tests, the cost is not very high. The only thing I know about this testing is that manufacturers only find out if their tires were tested if their tires fail repeatedly. NHTSA retests if there is a failure to be sure the failure isn't a fluke - and if it isn't, they inform the tire manufacturer of the non-compliance. Likely this would result in a recall AND a fine. |

|

Historical Background: When the US Department of Transportation was formed in 1966, the National Highway and Traffic Safety Administration was also created. They have jurisdiction over all cars, trucks, and related equipment - including tires. The first standards were published in 1967. They are called the Federal Motor Vehicle Safety Standards (FMVSS). The first tire standards were FMVSS 109 and 119. FMVSS 109 covered car tires and tires for trucks less than 10,000# GVW and FMVSS 119 covered tires for trucks over 10,000# GVW, tires for motorcycles, and tires for certain specialty vehicles such as trailers. The tests stipulated by the standards were pretty much industry standards tests - EXCEPT - the tests had some quirky differences. -- Editorial Comment: I do not understand why the US government regulators feel the need to "tweak" things so they are different from international standards, industry standards, and the way people currently do things. This is a pattern that has repeated itself many times. |

|

|

In the summer of 2000, following several months of turmoil, Firestone was forced by NHTSA to recall a huge amount of tires that were OE on the Ford Explorer. Part of the whole debacle was that Congress felt that NHTSA was "asleep at the wheel" - that they should have been searching out problems, rather than reacting after problems were found by others. As a result, NHTSA published an update to the specified tests:

|

|

PLUS, there was one more very important change made: Early Warning Reporting Every quarter, every tire manufacturer has to report on what warranty tires they accepted for that quarter. This is so NHTSA knows as early as the tire manufacturer does about any potential issues. Since this is a US regulation, only warranty returns from the US count. What doesn't count is any tire over 5 years old and any warranty claims other than endurance failures - such as vibration, appearance, road hazard, and wear warranty claims. Also reported is what we used to call "Legal Claims": property damage claims, (where the tire is claimed to have caused damage, but no personal injury), reports of personal injury and fatalities, lawsuits involving property damage, personal injury, and/or fatalities, and foreign (outside the US) recalls. And just be to complete, NHTSA also requires any manufacturer covered by FMVSS regulations to report their warranty claims as well. That means car, truck, and trailer manufacturers, as well as child restraint system manufacturers, etc. |

|

|

|