| B arry's Tire Tech This is a different approach to what I normally do on this website. I'm going to write a new entry every month covering whatever topics I discover during the previous month. I could talk about almost anything and I suspect some months I will have a lot to say and some months hardly anything at all! With that in mind, here goes: Oh, and the photo to the left? I was sent this by one of my many internet friends. The photo is one of his children playing with newly received tires. I thought it was one of the cutest things. I hope you find it as amusing as I did. |

| Blog: October 1, 2025 I stumbled on another YouTube Video advocating matching the dots on a new tire to the valve hole. This one had a better explanation, but - alas - it was just as wrong as the others. HOWEVER, the comment section had a number of people saying it doesn't work - and some of those related personal experiences. So just to be sure I've got my head screwed on straight, I consulted what Tire Rack had to say - after all they stock both tires and wheels and would be in the best position to know what is going on - and as I suspected, they not only backed up the "matching dots doesn't always do anything postive", they also had a list to show what tire manufacturers mark tires, and how they mark them - and it was not consistent (as I expected.) Further, they had a list that showed some of the OEM's and how they want their wheels marked - and again, most didn't use the valve hole as a marking device. ********************** I am writing this the morning after the NASCAR Bristol night race. As in the past, the race was about tires. This time Goodyear brought a really soft tire that performed well during the hot weather, but when it cooled off - as it does at night - the tire wore rapidly. The racers didn't know that until the race was some laps old. It caught everyone by surprise - well, not exactly. They didn't know, and they were wondering what was going to happen, but the wear rate was much faster than anyone was expecting. Teams wound up getting an addtional set of tires allocated, and even then, some used previously used tires to get them through the race. The amount of rubber that accumulated off line was ENORMOUS. Plus it made the top groove unusuable, There were a lot of tires worn into the fabric. As a tire engineer, I was interested in the construction of the tire and even the brief glimpses offered lots of insight. The Goodyear rep gave a pretty good "corporate speak" that this was what everyone had ordered, so it was all going to plan - Except, I think it was a problem. They should have learned from the past, and while they did to some extent, the fact that they had enough to supply everyone with an additional set - well, it does show good planning, but it shouldn't have been necessary. What I think should have happened is instead of a rubber compound that wore rapidly, they should have brought a tread compound which slowly degrades in grip. That way the need to get new tires becomes a matter of strategy, instead of a matter of necessity. Can't wait until next year! ********************** I ran across a YouTube video from Anton Petrov explaining how ice becomes slippery - and it's different than the normal explanations. It seems that ice, a crystalline substance changes to an amorphous substance under pressure. It changes back when the pressure is removed. That's different from melting and refreezing - which is the old way of thinking about this. The paper Anton cites is a theoretical study and needs to be verified by experimentation, but it explains some of the things that point away from the "melting" theory. This is not the first time I've encountered different states of matter. Another example is glass transitions like for nylon. Here's the video: ******************* September 1, 2025 I've been seeing the term "All Weather" being applied to tires other than passenger car and light truck tires. The verbiage always mentions the 3PMSF symbol - which I thought only applied to passenger car tires and LT tires, and not any other kind. This might be because the control tire is a passenger car tire. Doing a bit of digging, this seems to be a European designation, so I must be missing something as I don't think you can apply the symbol to anything other than passenger car and LT tires - but for sure, it doesn't apply to the US (and perhaps Canada?). ******************* Tire Technology International, an on-line magazine reporting on all aspects of tires internationally, reported that Continental just introduced a line of tires specially designed for self=driving and autonomous vehicles. I read the headline and immediately thought this was mostly a marketing move. Reading on, I learned that a stiffer sidewall can be special ordered to improve durability! WHAT!! Sidewalls are not the problem with tire durability. The rubber between the 2 belts is. Reading on, the tire line is offered in taller and narrower sizes because taller tires are better carrying the load of heavy vehicles. WHAT!! It's the tire size that controls the load carrying capacity - the bigger, the more load carrying capacity - bigger meaning any of the 3 numbers in the size. What a bunch of marketing crap!! Here's what I think is going on: Makers of self-driving and autonomous vehicles are going to be selling mostly to fleets, where cost of operation is extremely important. So the tires are going to be low rolling resistance and long wearing - 2 properties in opposition to each other - except you can get a moderately good compromise if you sacrifice traction, especially wet traction. I suspect the vehicles would be programmed to slow down when it rains, so wet traction isn't as important. Further, it is easier to get a good ride if the sidewall is taller. The stiffer sidewall? Probably playing off the ignorance of people who would make purchasing decisions for such fleets. I see a potential legal problem as compromising wet traction could be the source of a lawsuit if the vehicle were involved in an accident where the stopping distance in wet conditions. A sharp lawyer will be able to argue that sacrificing wet traction is being balanced against cost - and that argument plays very well with juries. ********************* August 1, 2025 Once again the YouTube algorithm strikes. I was doing research into bias tires, so the YouTube algorithm thinks it should send me a ton of videos on all sorts of aspects of tires. It is truly amazing how much misinformation there is out there - and worse, how many people are willing to make a video that passes on such information. Dunning-Krueger effect!! I must remember not to be such a person. ********************** The August 2025 edition of Grassroots Motorsports magazine had an article on tire preservation - that is, heat cycles and tire aging. For those who don't know, when a tire heats up, the tread rubber compound changes. In racing, they call a single heat up / cool down a heat cycle. Drivers can feel the difference between tires with lots of heat cycles and those with few to none. And here's where the engineer in me comes out. I am not a rubber chemist, but I do understand heat and heat history (the Arrehenius Equation - look it up.), and while Grassroots got this most correct (according to my understand of how chemistry works), they did get a few things wrong. The good news is that everything they said doesn't matter. When folks race, they use up tires. It's a fact of life in racing - and you can only get so much out of a set of tires - and you will know it when that happens. Where the good news is = their explanations are what I disagree with, not their description of what happens. Those sorts of things are not critical. *********************** I got a notice of a recall of Michelin tires. They didn't have the letters "DOT", which would be required for all tires sold in the US. The interesting part was that Michelin was not the the company recalling them. A retailer from Italy was. According to documents filed with NHTSA, Dealer Tire noticed the lack of the letters on one size. They informed their importer - Centropneu SRL - of the problem. Dealer Tire is a company that specializes in supplying car dealers with tires - especially OE tires. I suspect that Centropnue SRL is one of their European suppliers. Why don't they buy directly from Michelin? I don't know? Cost? At any rate, as importer of record, Centropnue SRL is the responsible party for the recall, not Michelin. I am sure there is more going on here as normally Michelin would be doing the recall. I suspect the tires were a "European Only" version that weren't supposed to be sent to the US and I'll bet Michelin is forcing Centropnue SRL to do the recall to teach them a lesson. I'll bet Centropnue SRL doesn't have authorization from Michelin to ship to the US. ******************** Tire Business headline: "Kumho targets growth to become 'top Tier 2' brand". Funny that! I've always thought of Tier 3 brands as "Cheap" brands - tires you only put on when you are selling the car. - And Tier 1 tire brands as the leaders - the big guys! And Kumho was - in my mind - in Tier 2. I don't have an opinion on where the line between Tiers is, but for Kumho to be the top Tier 2 brand would be quite a leap up. ******************************************************************** July 1, 2025: The European Union has opened an investigation into Chinese made tires for artificially lowering prices. The accussation is that they had government subsities to be able to lower prices and the intent was to drive out competition. ************************** For the very first time, I encountered HL tires. I had not seen any even though I learned of their existence as early as January, 2021 and wrote an artcle on them 18 months later (August, 2022). What prompted me to dig a little deeper was a YouTube video that specifically mentioned them. Somehow there was a connection to a new electric vehicle, Lucid. Tire Rack does indeed cary them. But as I feared, there is a lot of potential confusion. If you only go by the numbers in the size and don't pay attention to any of the letters or the load index, it would be easy to put on the wrong type of tire. This is especially troublesome as HL tires are expensive. While I'm not going to experience it, this could mean trouble for both consumers and tire dealers. ************************************** The other thing about HL tires is that they appear only on EV's that were designed from the start to be EV. That was not what I had the impression was the purpose of HL tires. Weird!! *************************************** I was doing some research and the YouTube algorithm decided I needed to see videos about dots on tires. I took a look at a few. Boy, was I disappointed. I think only one of them got it right. Several were way far off. Sort of makes you wonder! ******************************* June 1, 2025 The YouTube algorithm decided I wanted to see lots of videos about EV tires. But it had an unintended result. It's clear that Hankook has given a bunch of YouTuber content creators some incentive to promote their EV tires - mostly likely free tires. It's what I would do in their place. Here's the problem I have with this: Part of the sales copy includes some bogus technical reasons to buy these tires over regular tires. One of them is that is that somehow regular tires aren't suitable for EV's - which not true. The tire doesn't know what is powering the vehicle - gasoline, diesel, or electricity - so whatever benefits a particular tire gives is the same regardless of the powerplant. Another is the claim that tires designed for EV's have more load carrying capacity. Sometimes this claim is hinted at, rather then being explicit. This is just not true as the load carrying capacity of a tire is set by the Tire Standardizing Organizations, and they don't delineate a difference. But I will admit there is some advantage in noise and rolling resistance for EV specific tires, and that EV's benefit more than ICE engined vehicles. I go into more detail on my webpage about EV tires. ******************* I see where Continental is closing its Malaysian tire plant which it acquired from Sumitomo - AND - Apollo is closing its plant in Holland which it acquired when it purchased Vredestein. In both cases, the plants are old - so it reminds me that one of the problem in the world today is that it is more cost effective to start with a brand new manufacturing facility than it is to modernize an old one. This doesn't count the fact that many governments are willing to offer incentives to build new plants in their area. Which means that employees of old plants out to lunch. This is not going to change . Even when the wages in some places become more in line with the rest of the world. I noticed this pattern back in the 1970's - and, yet, here we are. ******************************* According to Tyre News UK, as many as 20% of the tires in the UK may be running below the 1.6mm minimum. This is a bit more than I expected. Given that the UK is a pretty rainy place, I'm having trouble imagining that drivers wouldn't notice the hydroplaning. On the other hand, maybe not many people in the UK drive at speeds that would generate hydroplaning.****************** May 1, 2025 The April 7, 2025 issue of Tire Business, a publication devoted to news about the tire business, had an article about a group that was going to build a tire factory in the US to build 3rd tier private brand tires. What I found interesting is that making tires is a machninery intensive process, and that means a lot of money upfront - long before the first tire is made. Usually established companies build new plants, so someone starting from scratch is remarkable. Not only do they need the machinery, but they need expertise to install the equipment, run the equipment, design the tires, set up the rubber chemistry, etc. That is a formidable task. They are going after a segment of the market where performance isn't as important, but still ...... Even 3rd tier tires have to perform at a certain level - albeit lower than name brand, premium tires. I am pretty sure I could provide the necessary expertise from the engineering design point of view - and I am sure I could find people to fill the necessary expertise in all the other ares, but it would be expensive and time consuming to find them all. This ought to be interesting. The company is American Tire Works and they are building the plant in Tulsa, OK. The article didn't say what brands they were going to produce, but private brands are usually built alongside name brand, premium tires, utilizing basic construction of those same premium tires, but with compromises made in the tread to reduce the cost - both rubber and engineering. Startup was stated as perhaps as early as 2027. **************** Tyre News (UK) reported on April 8, 2025 that the Thailand government is investigating an allegation that a tire manufacturer in China was shipping whole tires to Thailand and rebranding them as being made in Thailand. Given the reputation for Chinese made tires, it is understandable that Thailand would be concerned.The article implied that the investigation was triggered by a report by the UK government. ********************** The NASCAR Cup series went back to Bristol where a year ago, tire problems were the key issue for the race. This year was quite different. Even though there was lots of tire wear during practice, the track applied a traction compound to the track and that completely solved the tire wear problem - to the point where tires lasted entire stages. Tire falloff (what they call the difference in lap times between new and worn tires) wasn't very high. There wasn't even an advantage to replacing tires early to get track position. I suspect that Goodyear got so burned last year, that they brought a fairly wear resistant compound, but what I found really interesting was how effectve the traction compound was. I suspect there will be more experimenting, both here and at other tracks. ****************** April 1, 2025 No April Fools gag this month ****************** In April, 2024, (see below), There was a lawsuit filed against 6 tire manufacturers for price fixing. That lawsuit has been dismissed by a US Federal Court Judge. There is still an investigation taking place in Europe. ******************** It's now April, 2025 and the California Energy Commission hasn't published anything relative to the rolling resistance regulations they previously indicated would go into effect January 1, 2028, with a followup on January 1, 2031. I admit that is 3 years in the future, and while the industry has indicated it would take 3 years to test all tires, and it appears they are now up-to-date, the longer the lead time, the better. Besides, I see no reason for the delay. I am returning to my doubt that this will ever happen. *********************************** March 1, 2025 Oh, boy! Georgie Cooper and Jim McAllister (his FIL) are going to go to a tire convention! Be still my heart! Oh, Crap!! They went gambling instead! ***************************** Just got my 2025 ETRTO Yearbook. I was particularly interested in how they handled HL tires. It turns out they had a separate table - both for the sizes and the Load Index/pressure. The list of sizes was way more than I expected. On the order to 50 different sizes. I have yet to hear about anyone having them in stock or an OEM using them. *************** February 1, 2025 The news said that the Dunlop brand name has been purchased by Sumitomo. Careful reading of the news release mentions that Sumitomo now owns the brand worldwide EXCEPT for parts of Oceana (Continental) and India (Ralston Tyre, 2 and 3 wheel only). It is unclear who owns the Dunlop rights in India for passenger car and truck tires. ***************************** January 1, 2025 I've seen several articles about various tire manufacturers partnering with some company on RFID (Radio Frequency Identification) chips. This leads me to believe they are still very much in the development cycle. RFID chips have been under development for decades. If I understand it correctly, the chips have trouble surviving the curing process. If they don't achieve nearly 100% survival, then the tire has to be scrapped - which doesn't make sense - or segregated to be sold as such. Given that there are still announcements on partnerships, I suspect the technology is quite a ways from 100%. ********************* The California Energy Commission published a document - in my opinion, very late!! - about the Sep 30, 2024 meeting calling for environmental assessments for their proposed regulation. I commented on this in October, so this is pretty slow on their part. Worse, the deadlines published in this document were long past. They didn't publish the RRC values. Again, how are people supposed to assess the environment impact if they don't know what those values are. In my opinion, what they will only be allowed to set as limits that aren't going to impact things very much. Otherwise there will be lawsuits, However, they did publish a schedule: Jan 1, 2028 for the first set of regulations, and Jan 1, 2031 for the 2nd set. That is a change from 2026 and 2028 respectively. They also indicated that they were adding categories and that the RRC values would be different for each category. I'm still very interested in what they propose for the RRC values, which they've promised to be issued soon - whatever that means. ********************* December 1, 2024 I ran across a YouTube video claiming that the Red Bull F1 team was accusing McLaren of injecting water into the tires at the start of the Brazilian GP. The claim is that Red Bull used to do that, but stopped. The claimed benefit was that the water cooled the tire. The problem I am having with this is that others have claimed that one of the reasons for using nitrogen is to prevent water from causing MORE pressure buildup, therefore changing the balance of the car. I don't quite agree that that is the reason for using nitrogen, I get that erratic pressure buildup could adversely affect the balance. So I am not buying this. I think Red Bull is complaining because that's what Red Bull does. (Meaning Christian Horner) ********************* November 1, 2024: According to Tyre News UK, Germany is going to require winter tires for all cars starting Oct 1, 2024. They define winter tires as having the Alpine (3PMSF) symbol. After that date, winter tires with only the M+S symbols will no longer be acceptable. The article did not give an ending date for 2025 - or any other year. ********************** Saw an ad in Tire Business Magazine where a Medium Radial Truck tire - the kind on over-the-road 18 wheelers - with an Alpine Symbol (3PMSF). I don't think there is a test for that, and I think this is a marketing ploy. It won't be the first time a marketing department made stuff up! ******************** Just ran into a problem with how tire load carrying capacity is designated. The Europeans use Load Index and the US uses Load Range. Worse, there is a difference between Passenger car tires and tires designed for light trucks. The US uses the letter "P" in front of the size for P type tires and "LT" for medium duty pickups and vans. - BUT - The Europeans don't use any letters at all!! They use Load Index - and it's a bit difficult to explain and worse to actually work with. The tire industry needs to fix this - but they won't. A completely new system would need to be invented. Too much invested in the current systems. *********************** October 1, 2024: The NASCAR Bristol race took place late in Sept. It was at night and much cooler than the earlier race. The tires performed like they always did - some drop off, but the track rubbered up and there weren't any issues. If I were Goodyear and NASCAR, I would do a lot of testing before next year's day race.********************** California has set up a meeting to review possible environmental effects of their proposed rolling resistance regulations - which have yet to be published. I don't know how they expect people to comment on a proposal they haven't published, but oh, well!! Nevertheless, that is movement and unexpected. ********************* September 1, 2024: I stumbled across a YouTube Short on the tires of the reconnaissance aircraft, the SR-71. https://www.youtube.com/shorts/MFLzHgUe7TY The verbiage was explaining why the tires on the SR-71 are silver, and not black. The reason is that there are aluminum flakes imbedded in the rubber to reflect the heat. That triggered the engineer in me. That means it is trying to reflect radiant heat - and that also means the compartment where the tires are stored during flight, doesn't get that hot - just the surface of the compartment. The verbiage also said the tires were inflated with nitrogen to over 400 psi. I've heard of pressures like that for other aircraft, such as the Space Shuttle.But the video had close up photos of the tires and here's what I noticed. The tire size is 27.5 X 7.5 - 16 (about the same as a 190/75-16). That's pretty small! 22 PR (Ply Rating). Car tires are done a little bit differently, but 22 PR would be 11 times stronger. That makes sense given the 400 psi inflation pressure. NYLON - the usual ply cord for bias tires. 239 Knots = 275 mph. I suspect that means the tire is rated for 275 mph for ground speed for landing or take-off. Reinforced tread. I suspect that means extra plies under the tread. Cut Resistant. I suspect that is why the it seemed to have wire filaments coming out of the tread. I am such a Geek!! ************************************* Related to the above: The YouTube algorithm decided that since I watched the video about SR-71 tires, it would show me SR-71 videos - AND - one of them was another about the tires: https://www.youtube.com/shorts/8kwyNT0lzpM This one said that the rubber was made with aluminum flakes to ABSORB heat during landing. What?? Why would you want to ABSORB heat? In tires, rubber has an upper limit above which the tires start to degrade, eventually melting and/or catching fire.So you usually want to expel heat. Note: Rubber also has a lower limit where below that temperature, the rubber will crack. So that lead me to look for more videos on the subject - as well as think this through as a forensic engineer. What else could I pickup? If I were the design engineer, why would I want to change the rubber? It occured to me that if the original premise was right - that the aluminum is there to reflect radiant heat - then I only needed to do the surface, and a thin sheet of rubber with the aluminum flakes applied over the tire in the last step of the building process would work. It could also be a paint-like coating applied either before or after curing. I found several more videos, and one of them showed the tread surface had worn into a black surface - just like there was a thin layer of silver over the surface!! There was one that said only the rear tires were silver and they were BF Goodrich tires. That makes sense in that the SR-71 was developed in the 1960's, and BFG was known as an aerospace company (including tires) in that timeframe. Just an FYI, BFG was merged with Uniroyal in 1985 and then the merged company bought by Michelin in 1990. Another FYI, the SR-71 was retired in 1989, but revived in the 1990's, and retired again in 1999. I caneasily see Michelin producing the tires through their former Goodrich plants and specs! Please note, I could read the brand on the sidewall in one of the videos. It said the rubber was silver for strength reasons (That doesn't make sense) It also said the tires were inflated to 415 psi with nitrogen to prevent explosions (not exactly - Nitrogen won't suddenly release oxygen to a fire that is already there. They do this for ALL aircraft.) Editorial comment: It doesn't seem to matter, even people who know better, inadvertently propagate misinformation. And the type of misinformation seen in these videos is typical for any type of tire. ************************************ None of contacts I had last month resulted in anything. That seems par for the course. ************************ The NASCAR Richmond race with the different options for tires seemed like it worked more like INDYCAR than F1, where the difference was relatively mild. In contrast, the Michigan race, where there was only one option tire, there seemed to be more fall-off. I think more work needs to be done on option tires for NASCAR (INDYCAR, too!) *********************** The August 26th issue of Tire Business reports that California may be close to issuing a regulation on tire rolling resistance. This is a surprise as it appeared they couldn't meet the terms outlined by the law that allowed them to do so. No details were put forward. ************************ August 1, 2024: A lot of things happened this month. I had several contacts from people who might offer future collaboration. These haven't played out previously, but maybe this time? ********************************** On the downside, I still haven't paired up with a rubber chemist, even though I had several people working on it. Oh, well!! ****************** NASCAR has announced they are going to try an option tire for the Richmond race. This is similar to what INDYCAR and F1. I think it works very well in F1 - not so much in INDYCAR. This should be interesting, especially considering what happened at Bristol earlier this year, where the tires weren't rubbering up the track surface and they got worn out - and when that happened the car suddenly lost speed. Looking forward to watch this! *********************************** I was contacted by a historian interested in the history of AlphaNumeric tires. These date from BEFORE the advent of FMVSS safety standards and therefore before the date code was standardized. I was only able to help him a little bit. ******************************** July 1, 2024: Another recall for missing date codes. This time Hankook. At least NHTSA is being consistent. *************************** Last month NHTSA was supposed to issue a new regulation covering rolling resistance in tires and how that would be displayed - according to a report of pending regulations published by DOT in Sep 2023. That has not happened. NHTSA has repeatedly postponed the issuing of the regulation starting in 2010.I expect them to kick the can down the road again. I think the only reason they published a date was because California was threating to issue their own regulation. It is now clear that California isn't going to do that. Speaking of California, the last action taken was to accept an agreement of confidentiality from the USTMA (US Tire Manufacturers Association) for a data file in Sep, 2023. That file contained an analysis of all the data presented to the California Energy Commission (CEC). Part of that analysis was sure to contain the fact that over 90% of tires currently for sale would be banned if the regulation went forward without revision - and that, of course, is not workable. Unfortunately, the law that the CEC was working against did not allow for any alternatives. Since I have not seen anything since then I suspect the issue is dead. I suspect the California legislature would need to issue another law to fix the problem - and I don't think they will. Meanwhile the state of Washington's legislature was working on a law very similar to the California law. They obviously ran into the same problem California did, but in this case the law never made it out of committee, so it's dead as well. *********************************** June 1, 2024: I don't know why I didn't comment on this earlier, but the USTMA announced on March 29th that a consortium of 30 tire manufacturers have identified 6 possible alternatives to 6PPD, an antioxidant and antiozonant, used by almost every tire manufacturer and other rubber producers. 6PPD has been linked to salmon kills in the US Pacific Northwest. The link to salmon kills was first reported in 2020, and efforts to ban the substance followed. The problem is the 6PPD is so widely used, so effective, and does not have good alternatives that a ban could cause major tire performance problems for consumers. It's been used since the 1960's. I'm glad the USTMA organized the search for alternatives and I hope for a good outcome, but I think this is going to take quite a bit of time. ********************************** Yet another recall due to missing date codes. This time it's Hankook. Rules be rules! ********************************** May 1, 2024: I stumbled across a video on Formula 1 tires. YouTube: How are F1 Tyres Fitted? It was hosted by Will Buxton (one of my favorites!) and conducted by Albert Fabrega (not a fan!). Albert is a technical expert for the F1 YouTube channel - not employed by Pirelli. Here's what I got out: ALL the wheels are the same. They are made of magnesium by BBS. They are fitted with an FIA sensor and it appears no other sensors are allowed. The sensor is 180° opposite the tire valve. The wheels seem to have an FIA specified wheel nut. That might explain why some of the teams have had trouble with them! Each tire has a white bar code on the sidewall. They also have one on the side of the bead similar to some tire manufacturers do for passenger car tires. They use conventional mounting equipment, but it is specially set up for F1 wheels and tires. Albert said they use a kind of glue on the beads and the rim seat, but I think he got that wrong. I think they use a paste-type mounting lube and they use that to minimize the amount they put on. They inflate the tire on a separate unit. It took 2 psi to seat one bead and 26 psi to seat the other. They inflate the tire up to 60 psi, then deflate it down to 45 psi. They then scan the bar code and the data about mounting is encoded to a computer. They didn't say what gas they use, but I'll bet it is nitrogen and I'll bet that they can't use anything else!

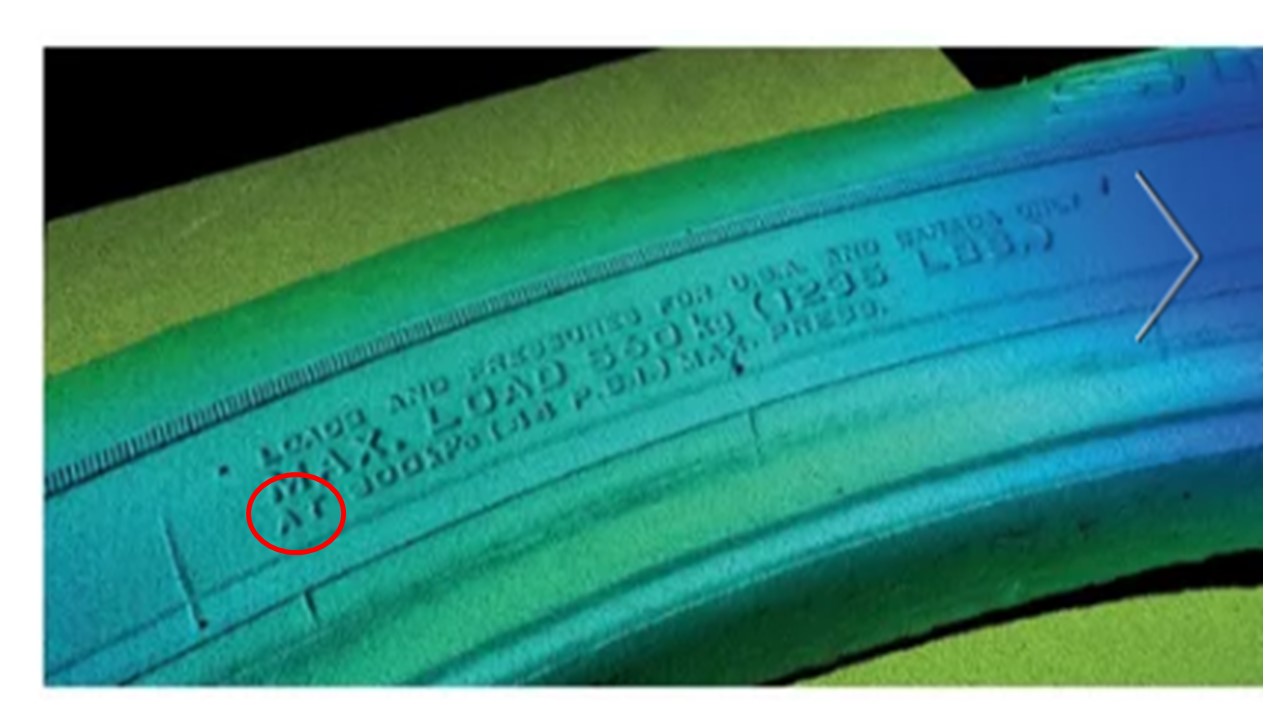

When the weekend is over, ALL the tires are sent back to England. They didn't say where they were made (I looked it up - Turkey! and they seem to ship them from there to the race.) Albert said, they dispose of them by burning them to make electricity, but another source says they burn them to make concrete. Burning tires to make concrete is a common way to dispose of tires. I've never heard of anyone burning tires to make electricity. ********************************** Every so often I am confronted by the fact that I am a Geek - specifically a Tire Geek I was looking at the latest issue of Tire Technology International and stumbled on an article about automated tire inspections. The article included a photo of a tire's load/inflation label - and it was wrong! Here let me show you:  It's the "AT" in the red circle. As a tire engineer I looked at the whole label and noticed that the max pressure is listed as 44 psi (300 kPa). That means, it's a standard load passenger car tire - and for those kinds of tires, the max load occurs at either 35 psi (242 kPa) or 250 kpa (36.3 psi), depending on whether the tire is specified according to The Tire and Rim Association (US based) or ETRTO (European based). In either case. It is permissible to inflate the tire beyond those 2 values - and the other alternatives are 44 psi or 51 psi. To my mind, the way to state this is either: "Max Load XXXX, Max pressure YY" OR "Max Load XXXX at 35 psi (or 250 kPa)". To do otherwise is misleading! /end rant **************************** In the Apr 8, 2024 issue of Tire Business, a trade magazine for the tire industry, there was an article indicating that "The Wheel Group", a company in California which distributes tires, has halted sales of its AMP brand non-mud-terrain tires because they didn't meet the US and Canadian standards for the Alpine symbol (aka 3PMSF). The tires did meet the European standard. As noted in my article on winter tires, there are 2 tests that can be used for the symbol. What I didn't know was that the US and Canada don't approve of the ABS braking test (aka UN ECE R117) . They only accept the ASTM F-1805 test. Interestingly, the company tested the tires using F-1805 and they failed! Apparently, they are planning on recalling the tires. I've updated my article to reflect the fact that the US and Canada only accept the ASTM test. ******************* Also in the April 8, 2024 issue of Tire Business was an article indicating the Michelin had ranked number 1 in several JD Powers surveys of OE tires. I have a problem with these surveys. They are an add-on to the vehicle manufacturers on initial quality. These surveys are the standard within the auto industry. HOWEVER, the problem with tire portion is that there is a "Halo Effect" - that is, if a tire appears on a vehicle with a high ranking, then the tires tend to get a high ranking - and vice versa. Nowhere in the survey is this accounted for. Michelin is known for being very careful to make sure its tires go on potentially high ranking vehicles, and avoiding potentially low ranking vehicles. They do this by the price they offer the car manufacturers. They are not supposed to do that, but they play this game very well! The good news is that I don't think most people pay much attention to the JD Powers surveys. ******************************* In the Apr 22,2024 issue of Tire Business, a trade publication for the tire industry, Pam Oakes pointed out that 5 states do not have any tread depth minimums! They are Montana, North Dakota, Arkansas, South Carolina, and West Virginia. It should be noted that the Federal government is not allowed to specify this, but they can specify what the tire manufacturers do during the manufacturing process - and they do. They currently require an indicator when the tires reach 2/32nds of an inch (1.6mm).

She also noted that some states require 4/32nds. ****************************** Stumbled across a YouTube video where Michelin was unveiling its latest airless tire. The video said that Michelin expected to have a tire marketed within the next year. The problem is that they have been saying that for 30 years. There are technical issues that don't seem to be solvable. ******************************* I got a notice of a recall by Goodyear of 82 tires for - get this - not having a date code. This does not affect how the tires would perform. I get that the tires aren't compliant to the regulations, but "Really?". I suspect this is NHTSA exercising their regulatory muscle and I suppose they needed to do that to make sure tire manufacturers are paying attention. ******************************* April 1, 2024: Tire Business reports that 6 tire manufacturers have been sued in a class action civil lawsuit in both New York and California for price fixing. They are Bridgestone, Continental, Goodyear, Michelin, Nokian, and Pirelli. This is on the heels of the EU raiding 5 out of the 6 for antitrust activities - Goodyear, not being raided. I suspect I'll have to write an article about how I think tire pricing works. ************************ I am writing this the day after the NASCAR Bristol race and it was all about tires! First, enough tires were worn to the cords that I could tell some things about the actual construction of the tires - namely the tires have a single circumferential cap ply, the belts aren't steel (probably Kevlar). I'm not sure about this, but it maybe that there was only one belt. This doesn't make sense to me, but I think it might be possible, albeit with a lot of plysteer. (See my webpage on Force and Moment.) If you didn't watch the race, the tires were wearing pretty fast because the track surface (concrete) was not "rubbering up" - meaning the rubber wasn't getting imbedded into the macrotexture of the track so that at least part of the surface the tires was running on was the rubber being abraded off the tires, which is what normally happens. It appears that everyone was surprised by this. NASCAR wound up releasing another set of tires to the teams to make sure the teams had enough tires to last the race. (They started out with 9 sets, plus a set from qualifying, plus the set from NASCAR, for a total of 11.) What happened was that the cars were capable of running much faster at the expense of tire wear, and you could burn off the right side tires in a few laps - either the front or the rear, depending on how the car was handling. If I were Goodyear, I'd be assigning the fix to the rubber chemists. To my eye, the compound was too dry (You should take this with a huge dose of salt, because rubber chemistry is a weak point for me.) HOWEVER, it made for a very interesting race. It challenged the drivers and the crew chiefs in ways they never imagined they'd be. I hope Goodyear doesn't change things too much because the sight of a front runner suddenly dropping back because he burned off his tires really spiced things up!! March 1, 2024: Apparently India limits the imports of tires to its market. The latest is that they have now added 70 tire make/models to their mandatory quality standards and taken them off the exempt list. I don't understand how this works. ************************************** Tire Business reports that Bridgestone is suing Apollo tires over the use of the name "Pinza". Bridgestone claims that the use of names ending in "nza" are characteristics of BS tires citing Potenza, Turanza, and Alenza as examples - and that this name creates confusion. BS brought a case before over the name Milanza by Federal Tires. BS lost in the lower courts, but won on appeal. I find this fascinating, but have no idea how this will play out. ************************ The European Commission raided tire manufacturers Bridgestone, Continental, Nokian, Michelin, and Pirelli claiming antitrust activities. I don't know what to make of this. It is interesting who was not raided - Goodyear. Tire Business intimated that whistle blowers can get beneficial treatment for such activities.

******************** One of the problems I didn't anticipate when I started writing this blog was having to backtrack - fill in the details of some past issue so I could do an update. This next one is such an issue. The Washington state legislature adjourned without acting on a piece of legislation that would authorize their commerce department to set rolling resistance standards for tires sold in the state. That means the issue is dead and won't be acted upon unless a new bill is proposed at the next session. I doubt that will happen. So here's the background: A bill was proposed in the state of Washington that would authorize their commerce department to require the publication of tire rolling resistance for tires sold in the state and to potentially set minimum standards. This proposal sounds very much like what the state of California has proposed, but California is very much ahead of Washington in the process. The California Energy Commission (CEC) has proposed a regulation authorized by a law passed by the California legislature. The proposed regulation was announced in February, 2023 and comments solicited. The USTMA (US Tire Manufacturers Association) commented that the proposal would eliminate 99% of the current tires being sold and was therefore unworkable. The USTMA has subsequently supplied the regulators with data to help the regulators understand the issues. That was 6 months ago. I suspect the CEC will abandon the effort. In the meantime, NHTSA (National Highway and Traffic Agency), the US federal agency the sets tire regulations has said they will issue a rule for consideration in June, 2024 - HOWEVER - they have said they would do this starting in 2009, and keep kicking the can down the road. I expect that to continue. I go into more detail here: Barry's Tire Tech: Draft Framework of California's Replacement Tire Efficiency Program **************************** A friend of mine - Roger Marble - published a new post on his website RV Tire Safety: RV Tire Safety The one dated Jan 24, 2024. I don't know why it took me so long to notice it. But here's the thing: Roger and I have had a conversation on this issue and I decided not to pursue the point.- letting my webpage serve as my rebuttal. There's a part of me who wants to comment on the post, but I don't think it will serve the greater good. In essence our difference is over what actually holds up the load in a tire. I wrote up a whole webpage on the subject: Barry's Tire Tech: Footprint. Roger is stating it's the air pressure, not the sidewalls - and I state it's the sidewalls and the pressure stiffens the sidewalls. But I see his point. He's saying that folks should not judge a tire by the stiffness of the uninflated sidewall - and he's right!! The inflation pressure has way, way more effect. For example, a RunFlat tire has a really stiff sidewall - much stiffer than a conventional tire - and you only get a bit more harshness and no more load carrying capacity. So in the big scheme of things, he is emphasizing that inflation pressure is very, very important - and much more important than the sidewall construction. I am not going to dilute his message. |

| |