|

B arry's Tire Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Analyzing Failed Tires: In this article, I'm going to tell you how I analyze failed tires. By "failure" I mean a structural failure not caused by an outside source. I prefer to see the whole tire - inside and out, unmounted, and as many pieces as are available. But I realize that many people don't have a choice about the conditions for the inspection. I'll do the best I can to take that into account. First Step: Look for a puncture!!

Punctures are harder to see from the outside, therefore more difficult if the tire is still mounted. But if you have no choice, look very, very carefully. I suggest your eyes should be no more than 12" away from the tread surface, and look at the circumference at least 3 times. Trust me, as I have missed a few and learned the hard way! If you find a puncture, it is quite likely that you've found the source of the problem. |

|

General Principles: Tires are laminated composites. Laminates tend to fail between layers - and this is especially true for tires. In fact, we use the term "Separation" a lot when describing tire failures. That's because that is usually what happens - the layers separate from each other. Composites - a combination of a structural component surrounded by a matrix that holds the structural elements together. They tend to fail where the matrix bonds to the structural element. In tires, the structural elements are typically some sort of thread (cord) or cable (wire) and the matrix is rubber. As composites, tires rarely fail within a layer - that is, within the composite. The appearnce will be the cord or wire being mostly intact and (mostly) detached completely around the cord from the rubber matrix. The cord might be clean of rubber or it might have bits of rubber attached. Just be aware that sometimes a crack will follow the cord and the rubber will be more or less cleanly peeled off the cord or wire. If the failure is between the cord and the rubber, this is usually a adhesion problem. If you have a tire failure that isn't a separation or a composite adhesion problem, suspect an external cause. We usually call these "Road Hazards", and these are of 2 types: Cuts or Impacts (blunt force)

|

|

|

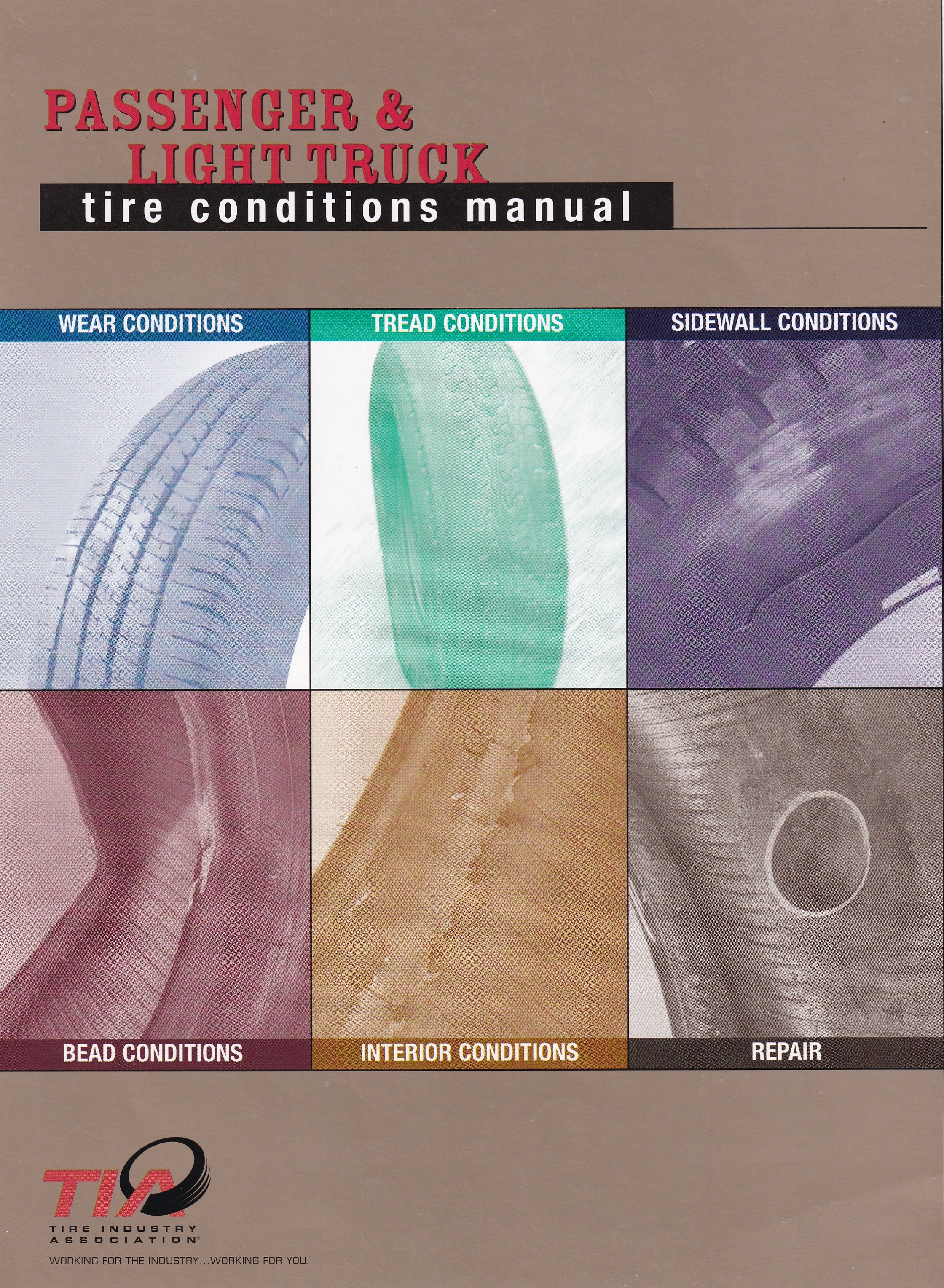

To the left is an image of the most definitive manual on analyzing tires. It is published by the Tire Industry Association (TIA), which is an organization of tire dealers, tire manufacturers, and related industries. The organization specializes in training and this manual is one of their resources.

The book has many, many pictures of tire conditions, along with an explanation of how to handle the situation. Not only does it tell you what the problem is - if there is one that can be remedied by the consumer - but by implication, whether the problem is caused by an external source - or not. I hope it is obvious that if the problem has an external source, it wasn't caused by a manufacturing condition (aka "defect") or a design related issue - which I will explain in more detail at the bottom of this page I had a hand in writing this book and it was a lot of work by many people. I have referred to it frequently since it was published. Here's how to get one: TIA: Passenger and Light Truck Tire Conditions Manual |

|

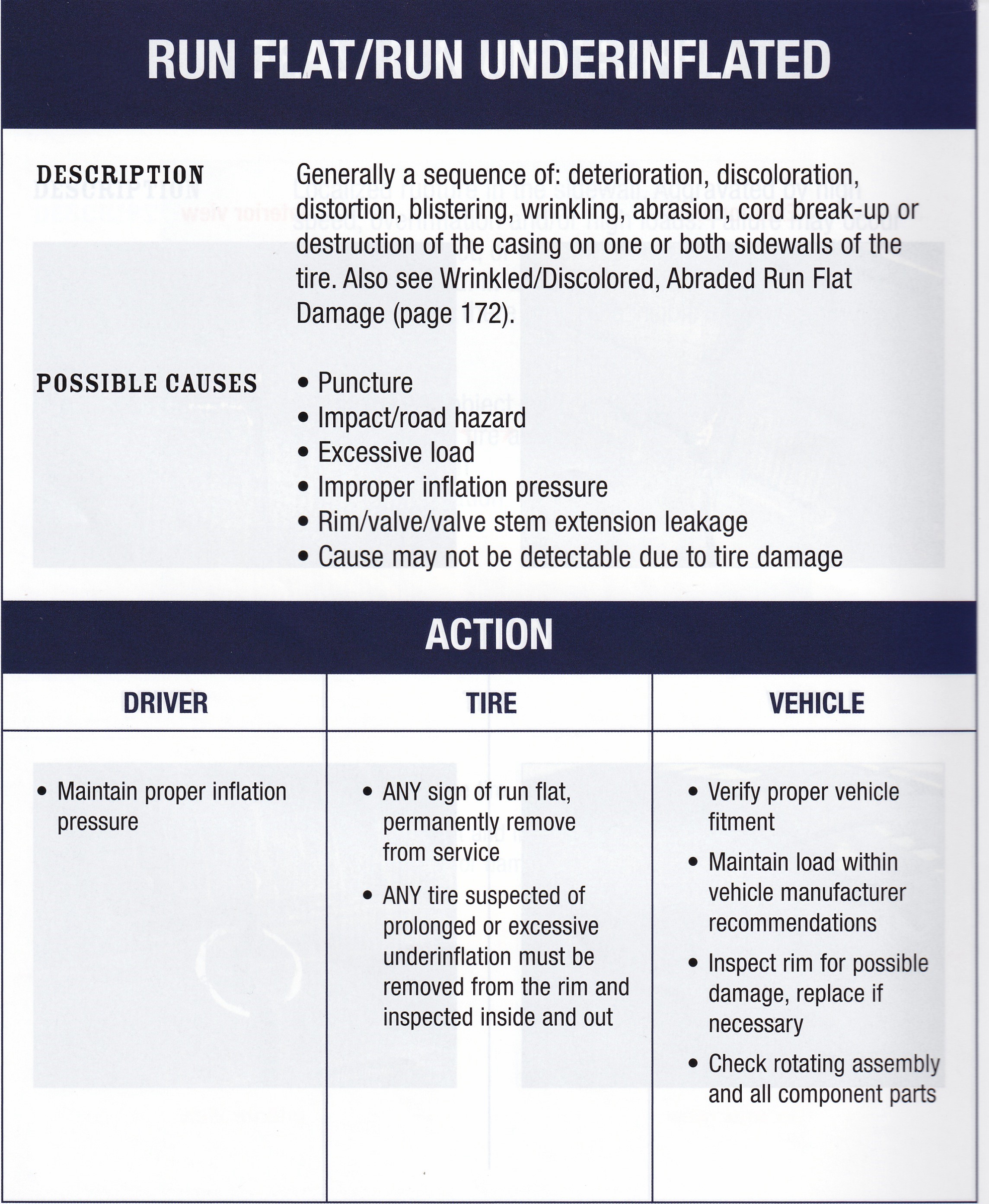

Yes! It's expensive ($285 as of the writing of this webpage), but if you are doing any kind of serious analysis of failed tires, it is essential - worth every penny! But look what you get: → → This is a page from the manual -

- and our first lesson: |

|

|

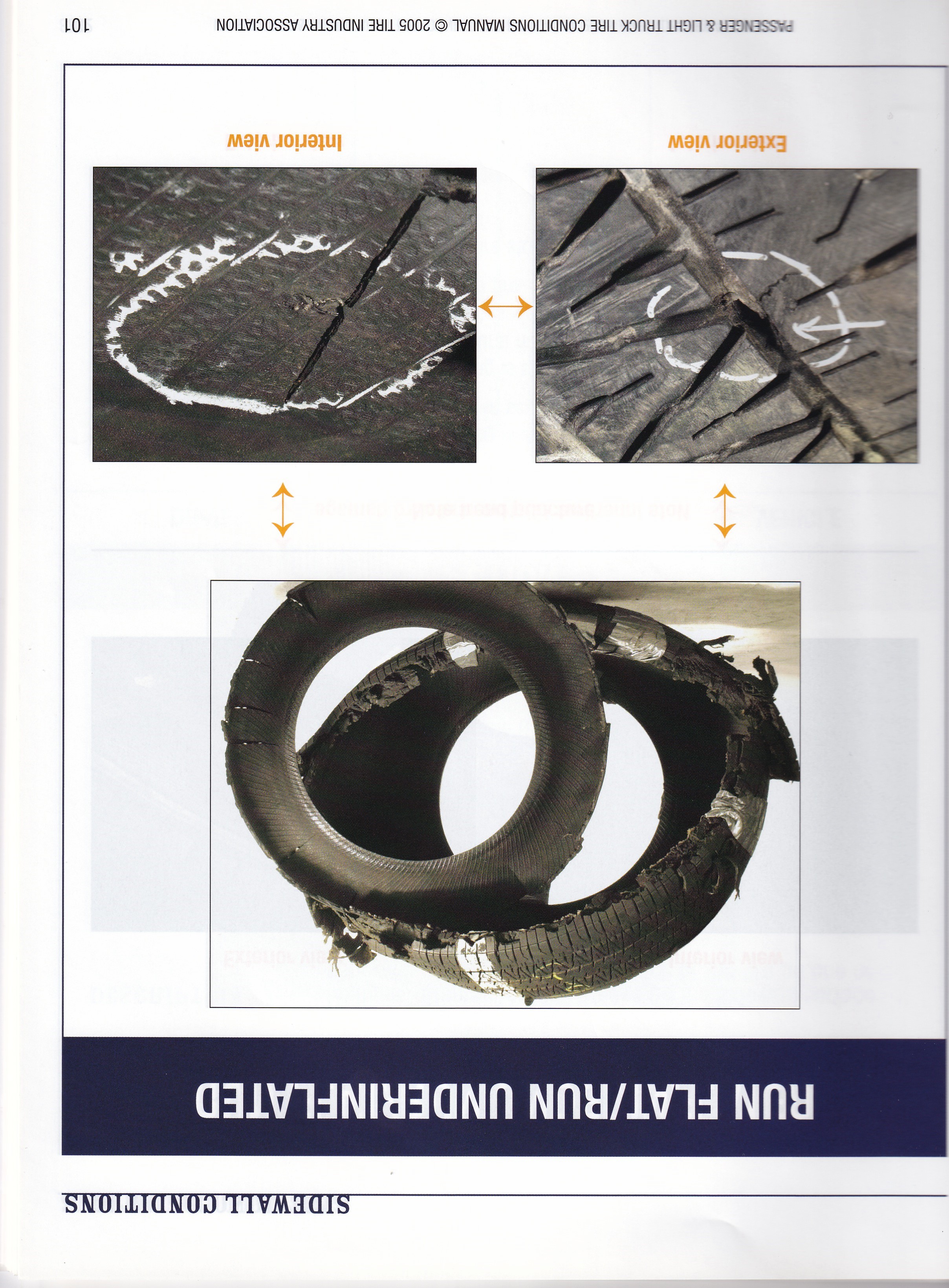

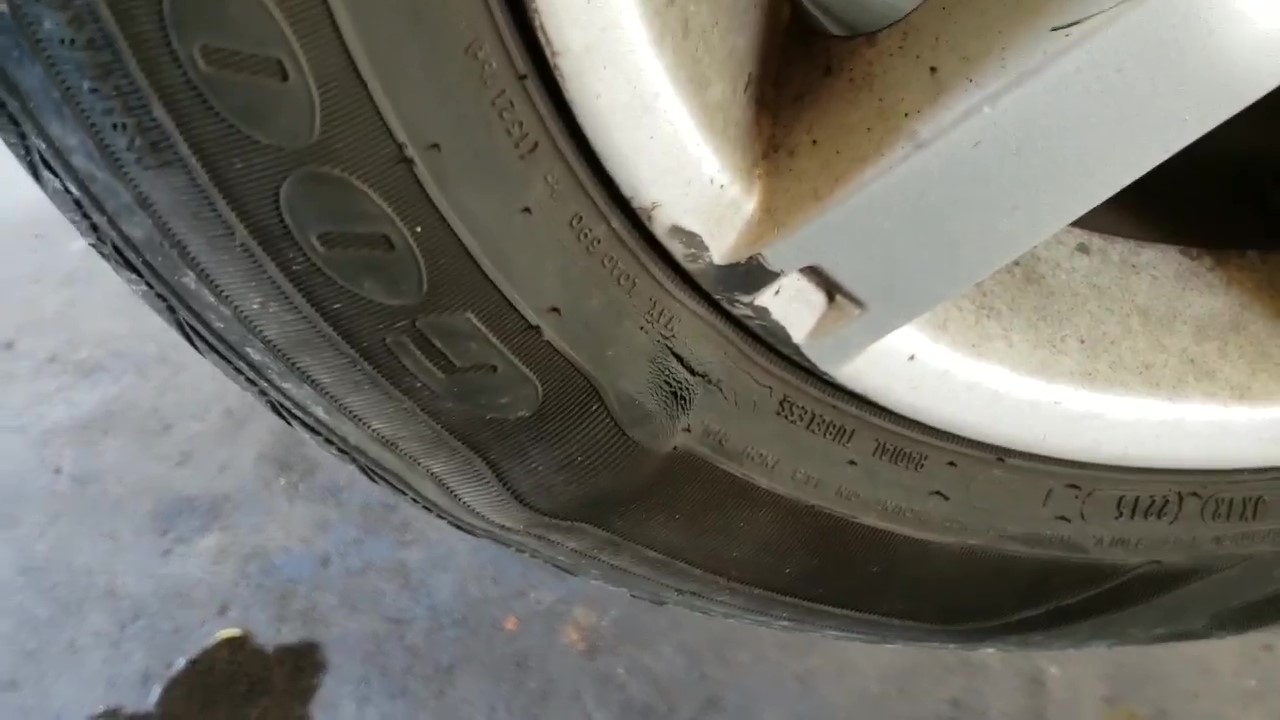

Run Flat Tires: Here's one of the photos. Run Flat means the tire was operated without the benefit of enough inflation pressure to keep the sidewalls from abraiding against each other. This usually means NO inflation pressure, but this can even occur with very low pressure! Notice that the tread/belt is a more or less an intact hoop. This is the most identifiable feature for this condition. Also notice that one of the sidewalls is completely detached. The variation is that both sidewalls can be detached, or just damaged. Then notice the photos of the puncture - inside and out! There's a 90% probablility that if the tire has this condition, you can find the puncture. What about the other 10%? The puncture was very likely in the area of the sidewall damage! And there are statistics to prove that. And - Yes! - a tire could have another source of the leak, but those are fairly rare. And this is caused by an external source - not a defect! And the only thing a consumer can do is try to avoid traveling where there is likely road debris! But the tire is scrap. It needs to be replaced. |

Let's look at some more Run Flats: |

|

|

|

The key to all of these is that the tread is basically intact in the form of a hoop, and only the sidewall is damaged, and the split is just south of the tread/sidewall junction. Confirmation would be if a puncture was found! Side Note: Keep in mind that all I am showing you are photos. There could be another issue in the part of the tire not in the photo. It's important to look at the entire tire. Also, it is not unusual to get contradictory information. Be aware of that! |

|

Impacts: To the right is an image of an aircraft tire failure. Notice that the failure is a V shaped opening. That V shape is very telling. Ya' see, this is a bias tire, and the ply fabric is oriented at about a 45° angle to the circumference. That opening is following the ply lines. Something weakened the tire to the point where the inside inflation pressure could start to break the ply cords in a zipper effect. The result is the opening you see. This is usually the result of a cut, but a dull object can start the cord breakage. There are variations on this theme: Y breaks, X breaks. |

|

|

To the left is a steel belted radial passenger car tire. This is also an impact break. Yes, it does look different, but the reason it does is because the plies are radial, but the belt is at an angle to the circumference. The failure is not following the steel belts, but failing along the ply cords - that is, radially! |

|

But the most common form of impact damage is broken ply cords and that results in a bulge. That is now a weak spot as the cords normally holding the inflation pressure in, no longer can - and while this tire didn't actually fail (as in lose air), it should be replaced. |

|

|

And if you have a mark on the wheel where the bulge is, even more proof the tire hit something. Be aware that sometimes the tire fails and those witness marks can be quite valuable in determining what happened. |

|

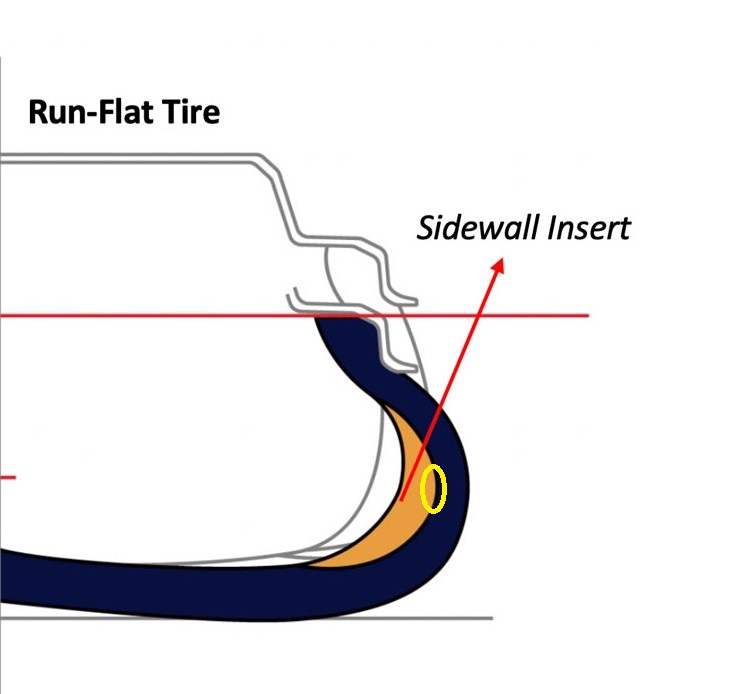

Belt-leaving-Belt Separation To the right is an image of the infamous Firestone ATX, which in 2000 resulted in a HUGE!! recall. I refer this whole debacle as the Ford/Firestone Controversy. I go into more detail here: Barry's Tire Tech - The Ford/Firestone Controversy This is the most common type of structural failure for a steel belted radial tire. That's because the most highly stressed area in a steel belted radial tire is the rubber just under the top belt at the edge of the top belt.

|

|

|

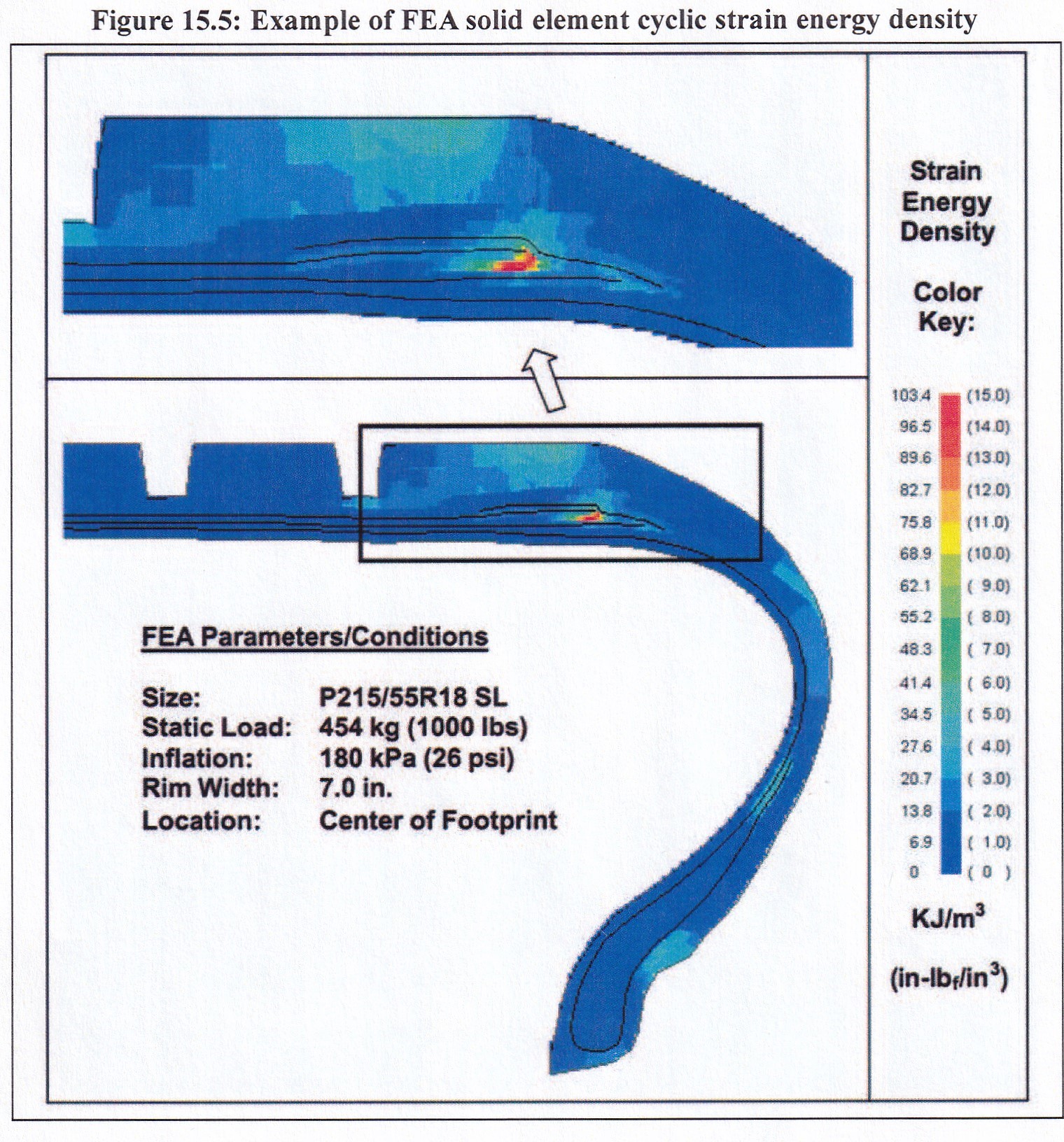

To the left is a image of the output of a computer model analyzing the amount of strain energy in a tire. I won't go into detail of what strain energy is, but suffice it to say a high strain energy is where failures would start. Notice the red area. It's under the top belt at the edge. This is where tread separation failures start. To make matter worse, this is also where the most internal heat is generated. In other words - the hottest part of an operating tire. That heat causes the rubber to breakdown faster. That's why inflation pressure is important. It not only reduces the strain energy, but the amount of heat generated as well. |

|

The sequence of failure is:

|

Here's a tire with a flap:

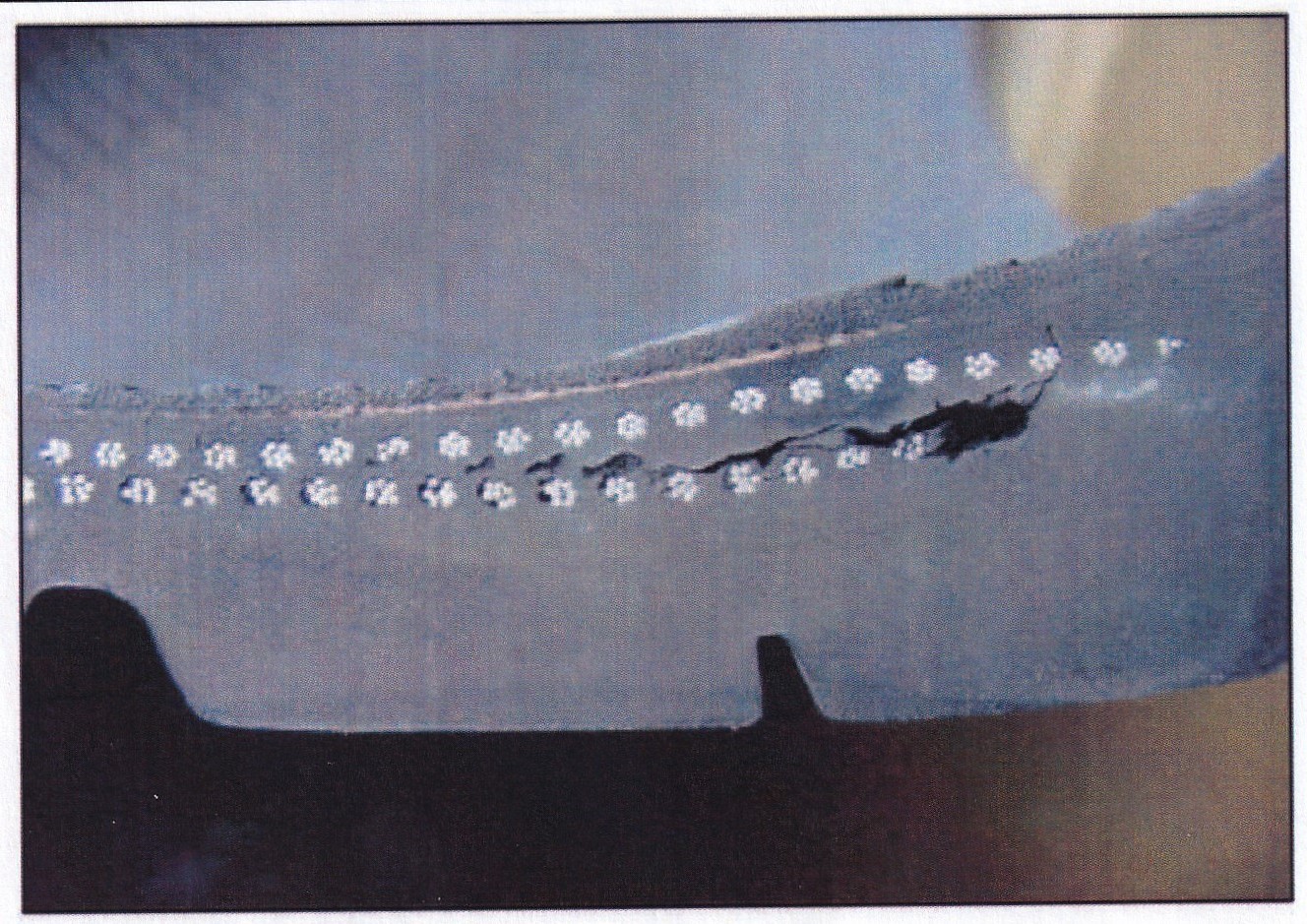

And here's the "hairy" area.

|

|

Here's a photo of a tire section with a tread separation. Notice the separation is largest at the edge of the top belt (In the photo, the section is upside down with respect to the way we normally identify "top" and "bottom".) and has even grown outwards a bit. Also notice the separation has grown inwards along the wires of the bottom belt, but isn't quite completely separated. In an intact tire, this would not be visible. |

|

Some variations: |

|

Here the flap has not yet been created. There is just a tread bulge.

|

Here the tread and top belt has partially detached.

|

Same here:

|

|

This is what you get if the tire has cap plies. The reason this looks different is because the cap plies do a good job of preventing the tread from bulging - so the bulge takes place on the sidewall. Also, no flap!

|

Complete tread/belt detachment.

|

|

|

So what can be done to avoid a tread separation ? 1) Inflation / Load!

2) No old tires! Doing those things won't prevent a tread separation, but it will minimize the chance. |

|

But to be fair, most tread separations, although fairly rare, are caused by an inadequate design - meaning there is something wrong with how the materials are specified. (Sorry, fellow tire engineers!) That could mean what we tire engineers call "Construction" - OR - the rubber chemistry (aka as "Compounding"). Tread separations are hardly ever caused by a manufacturing defect. (except that lawyers use the term "defect" to include design issues!) Design issues can not be determined by analyzing a single tire. There has to be a pattern of failures without identifiable causes. That's why informing NHTSA and the tire manufacturer is important! Both these places have people who analyze data to see if they can spot trends. |

|

|

If you think you have a design related issue, contact NHTSA and the tire manufacturer:

Contact the tire manufacturer through their 800 number. Use Google! Why? Because NHTSA is a place where the accumulated information can be sorted out. While a single tire failure is not enough to trigger a recall, it's a start. And contacting the manufacturer MIGHT get you a new tire and/or some form of monetary compensation. But the real reason is to give the manufacturer an opportunity to see trends. |

|

|