|

B

arry's Tire Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Analyzing Failed Tires: Part 2: Fun Analyzing Some Examples: So let's have some fun and try to analyze some failures from the internet. First, I recommmend folks don't try to analyze why a tire failed without having it in front of you. Even though I've done a ton of analyses, I know enough to know that nothing replaces being able to see the whole picture - and no amount of photos will be able to do that! With that said, let's have some fun with some examples I've pulled from the web!! |

|

Read the write up starting about post #29 Car Talk: Driving with a slightly bulged tire is dangerous I hope LoudThunder doesn't mind me using this as an example. Notice that while I commented above this post, I didn't comment on this failure at all - because the issue was over and settled by the time it was posted. Not only would I be commenting on a single photo, but I would also not be adding anything of value to the conversation.

|

|

So onto the analysis: Notice that the top belt has partially detached and split along the cord path. The bottom belt appears to be intact.

Further the top belt has that "hairy" appearance you get from a series of tears. If the failure weren't so localized I would say it was a belt-leaving-belt separation - the most common kind of failure for a steel belted radial tire. But |

|

|

|

|

NEXT: This tire has a circumferential split through the mid-sidewall. The split only goes about 135°. The rest of the sidewall has a different color in the same mid-sidewall area about 1" wide around the entire circumference including the area of the split. Notice the red crust above the sidewall split near the edge of the tread lugs. |

|

|

Here's a close up. Notice that the cords are unraveling, not cleanly cut. It's clear that the difference in color of the sidewall follows the cord split. In that area, the sidewall also appears abraided. There is also some writing on the sidewall that is cut off at the color difference. Conclusion: This is a run flat. There is likely a puncture somewhere in the tire. Further, the red crust is likely the Antioxidants coming to the surface and to my mind that indicates heat. So I think the puncture resulted in a slow leak and the sidewall split was where the sidewall contacted the road surface. |

|

Cuts vs Tensile breaks, vs compression failures. Need photos. |

|

|

Let's start with the obvious Tread: The tread is smooth; It has no pattern! These are frequently called "Slicks". Since most racing takes place when the weather is good, there is no need for a tread pattern. Less tread in contact with a dry road surface means less grip. A tread pattern is absolutely needed for wet weather (and dirt and snow, too!). But some of you may point to what you learned in high school physics: Friction is independent of the size of the area of contact. But what they didn't tell you is that this friction theory (aka Amontons' Second Law of Friction) doesn't apply to textured surfaces, and especially doesn't apply when one of those surfaces is made of a soft material - and a tire on a road surface has both! The (relatively) soft rubber penetrates the texture of the pavement and additional grip can be generated by tearing off bits of the tread rubber. |

|

That results in bits of rubber accumulating on the racetrack. These are usually called "Marbles", but I prefer the term "Clag", popularized by David Hobbs of F1 and broadcasting fame. This gets picked up by the tires, but expelled during cornering, so they tend to accumulate off the racing line.

|

|

|

But when the racing is suspended - such during a yellow flag situation, the tires will pick this stuff up. So it has to be removed - and the best way is with a putty knife with the help of a heat source, such as a blowtorch. And it has to be removed to reveal the important tread depth indicators - sometimes called "Dimples" (In the red circle). Those are molded into the tire during manufacture to provide a way to tell how much tread rubber is left. |

|

Speaking of tread rubber, racing tires use a tread rubber that is different than street tires. This would be a good time for me to say: "I am not a rubber chemist!!" If you are one, please contact me at I could use some help with filling in this gap in my knowledge. Anyway, if I have this correct, racing tread rubber compounds include resins, which get sticky when heated. That means that not only is the tread surface sticky, so is the clag! |

|

|

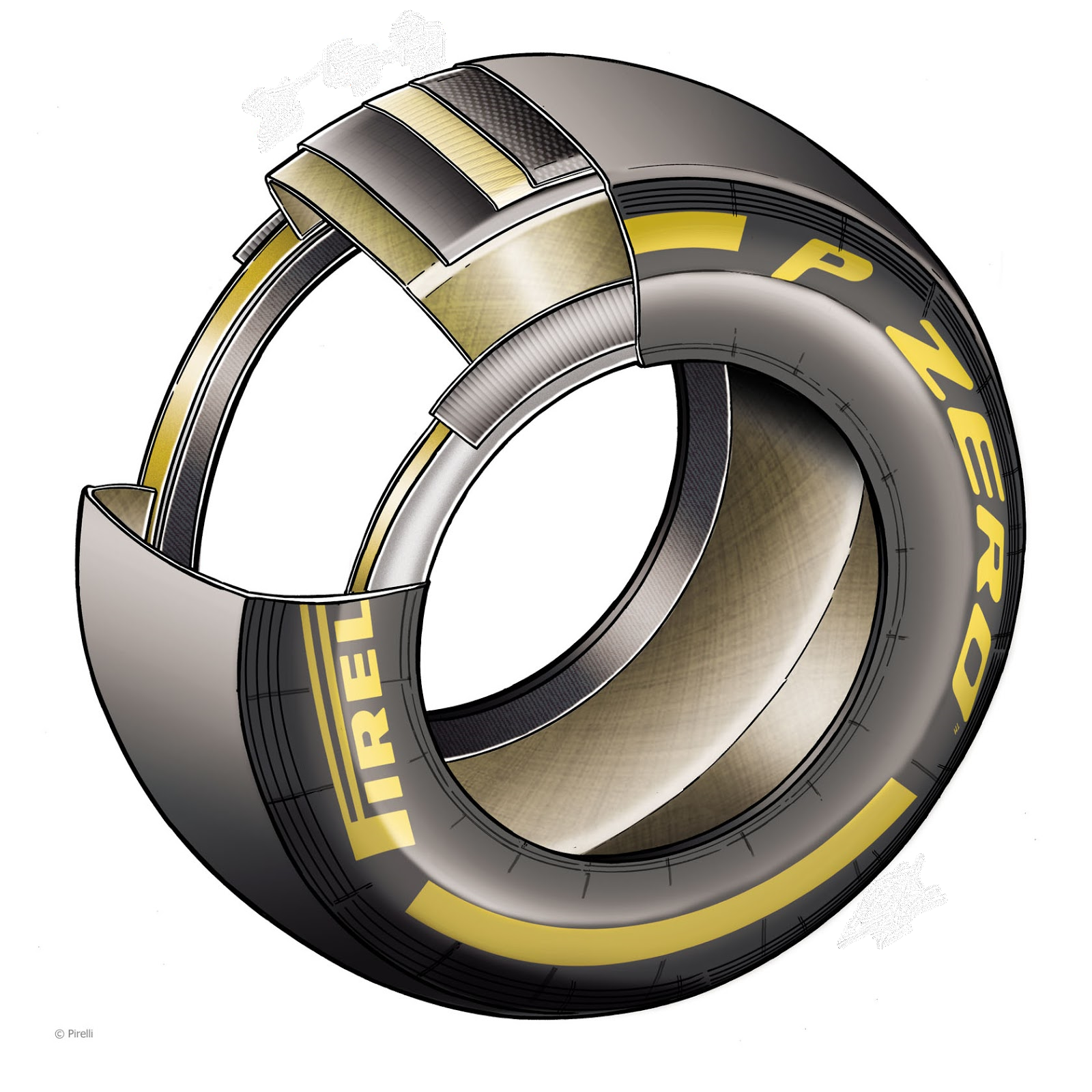

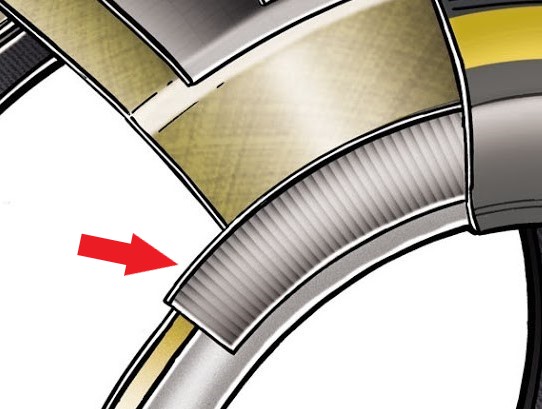

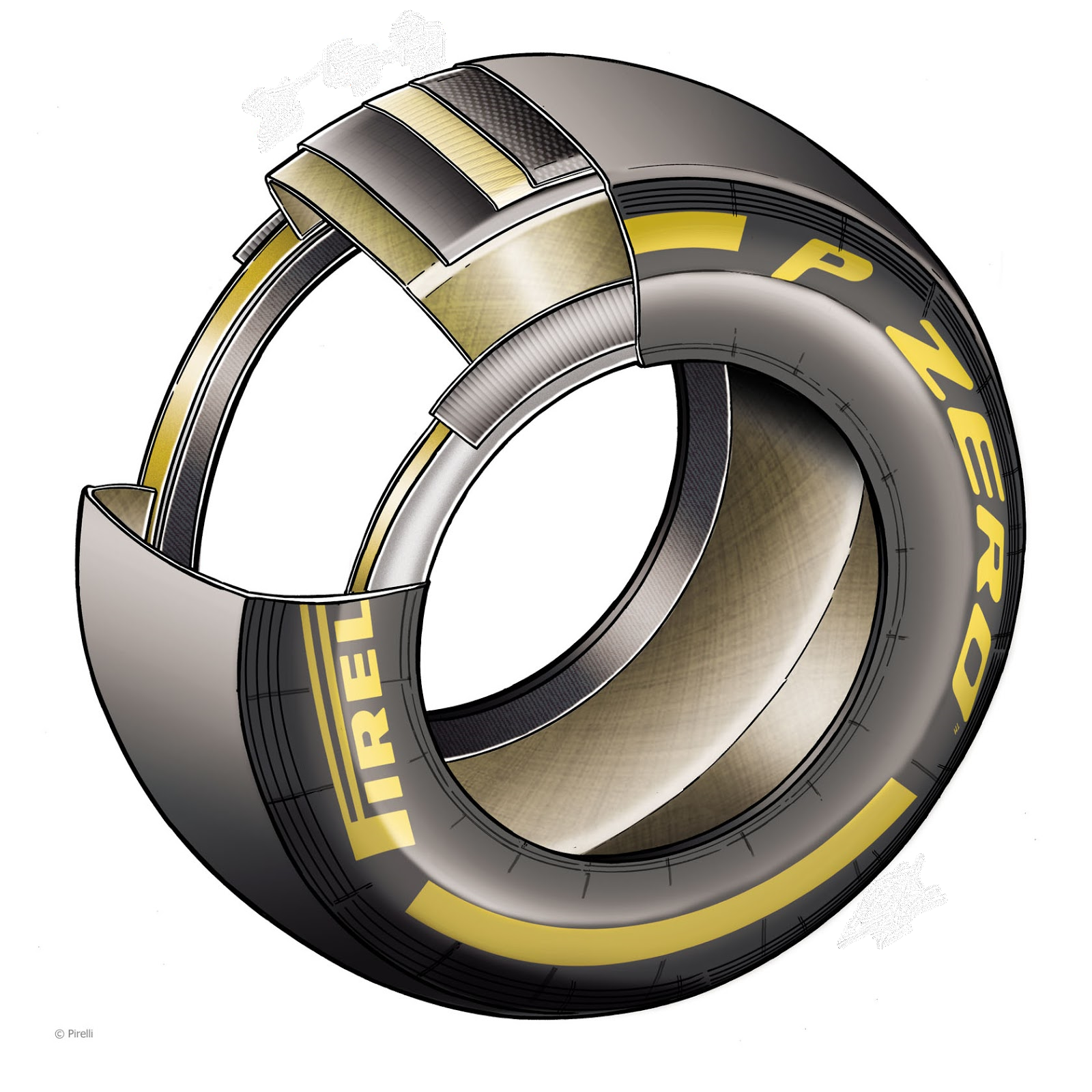

Sidewall: The sidewall is also different in racing tires. Since it is better for the tire to quickly react to steering input, they make the sidewall stiffer. There are a number of ways to do this. The image to the left is the same Pirelli F1 tire image above, but I've pointed to a thing in the sidewall. I think Pirelli is being deliberately vague here, but I would call this a "Chipper", which is a combination of a "Filler" and "Chafer" - both of which are parts of regular tires. The chipper is a fabric insert, usually at an angle (that is, neither radial, nor circumferential.) It greatly stiffens the sidewall. These are sometimes used in RunFlat tires. Further, street tires need to be protected from curb rash (as it is sometimes called). A layer of rubber is applied to the outside of the sidewall. Technically that layer of rubber is "The Sidewall" and what is underneath it is in the "Sidewall Area". Racing tires have no need for such protection, so they don't have such a feature. |

|

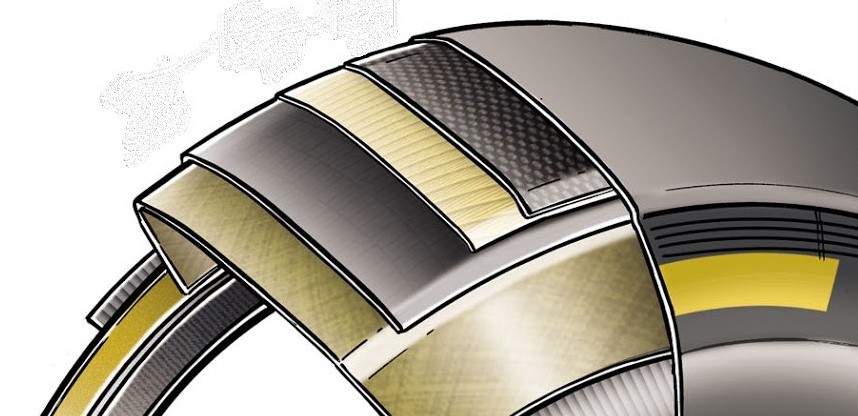

The Belt Package: Please note that this only applies to radial tires. There are no belted bias tires in track racing. And here is where this gets interesting for a tire engineer! In a street tire, the belt package has a number of features to get the tire to survive ten of thousands of miles. But racing tires only need to surivive a hundred miles or so - and that changes everything. Again, the image from Pirelli's F1 tires - and, again, they are being deliberately vague - but a sharp eyed tire engineer will notice those inserts aren't present!! From experience, I know that adding those rubber inserts EXTENDS the miles before the belt package starts to fail! I've looked very carefully when the TV shows failed racing tires, and it is clear they don't have those inserts. But what is also clear is that the 2 belts aren't always steel. Sometimes the top belt appears to be kevlar. I assume they do this because kevlar is better for high speeds. |

|

|

Other Stuff: Innerliner: Street tires use a layer of butyl rubber on the innermost surface of the tire because butyl is less permeable to air. But since racing tires only need to maintain pressure for the length of the event, it is not uncommon for racing tires not to have that layer. Please note that the image from Pirelli doesn't show a separate innerliner layer. (Boy, is this image useful!!) Radial Tires: It is not uncommon for radial racing tires to have as much as 15° bias to the plies - as opposed to more or less 0°. |

|

What about Dirt? Or Drag Racing? Dirt racing tires tend to be larger, using less pressure than paved track tires, have a soft sidewall and a tread pattern. It is common for dirt racing tires to be regrooved to provide a sharp edge that bites better. |

|

|

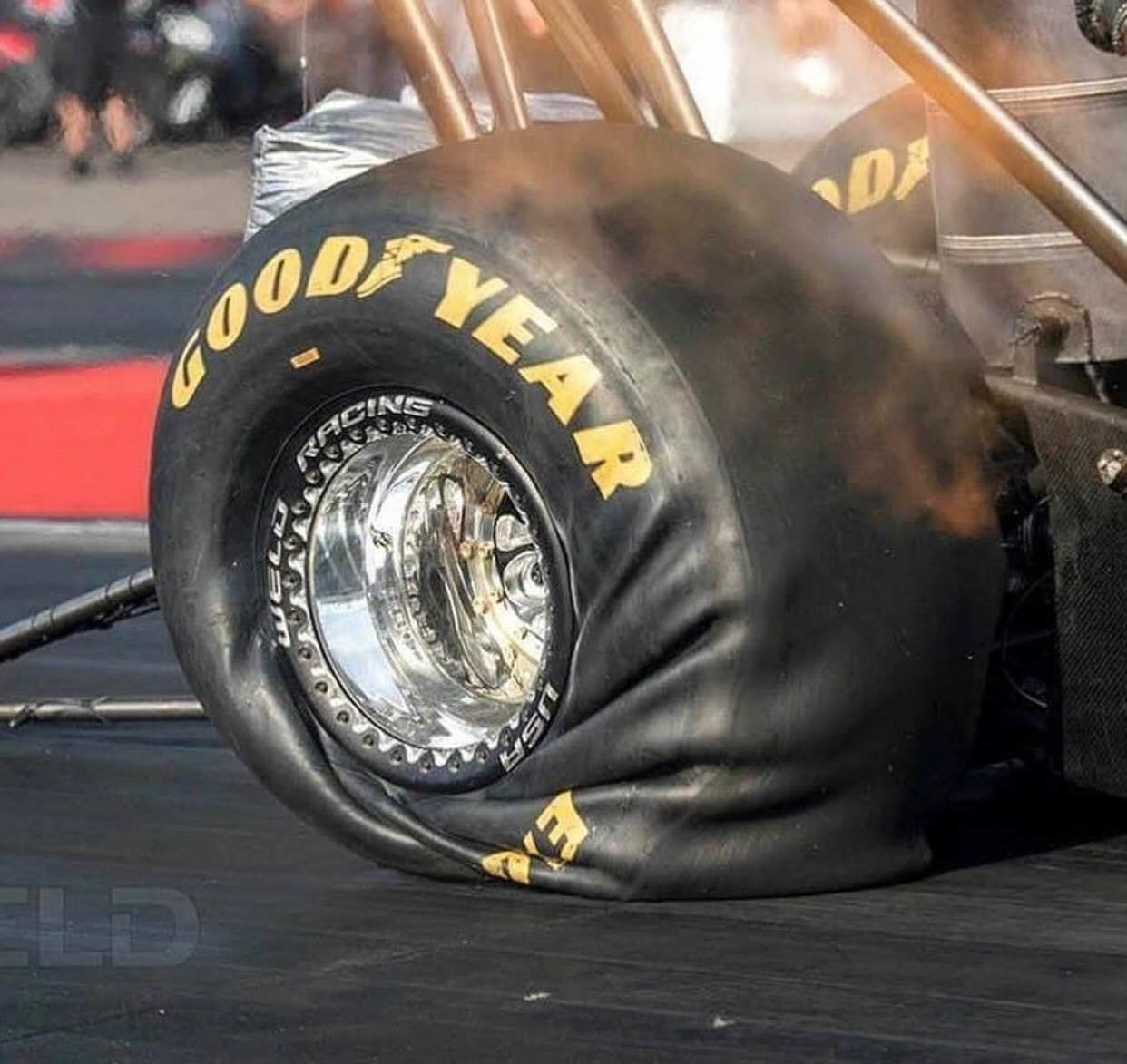

Drag racing tires are also large, have soft sidewalls, and use less inflation pressure. That results in the sidewall "wrinkling" during the launch process (We engineers call this "buckling"). The net effect is the tire "squats", with a larger footprint and absorbs a certain amount of rotational energy that smooths the transition from having no torque to have a HUGE!! amount ot torque applied. |

|

It is not uncommon for sanctioning bodies to mandated a "Spec Tire" - that is everyone has to run the same exact tires. Formula 1, NASCAR, IndyCar all do this. This is the result of several incidents where tire manufacturers were competing in the same series - the most infamous is the 2005 F1 Indy race. Short version: Michelin had problems and the FIA wouldn't accomodate them, so only 6 cars (out of 20) took the starting lights. Long version: Wikipedia: 2005 US Grand Prix |

|

|

But there are others: The SCCA limits certain "stock" classes to tires that have at least a 200 UTQG treadwear rating. This prevents the tire manufacturer from developing a tire with a super sticky tread compound. The reason this works is that the penalty for violating US federal regulations is soooooo much more severe than what the SCCA can impose. Plus sometimes there are minimum inflation pressures or maximum camber angles - both of which are to prevent tire failures. |

|

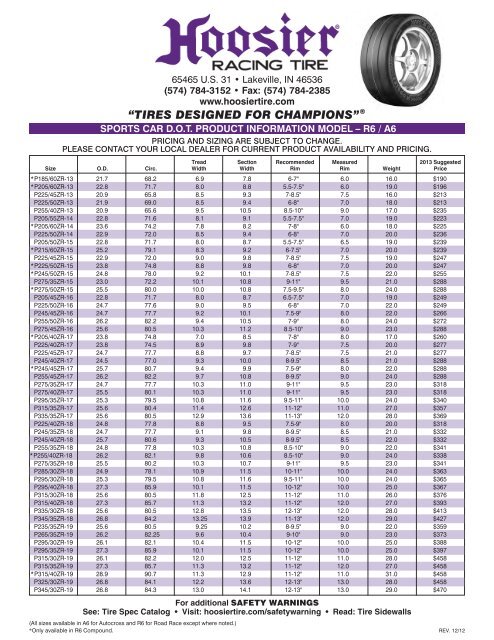

Some loose ends: Racing tires don't have to follow government regulations. That means not only don't they have a DOT number, they aren't tested for compliance to the regulations. So the specs have to be obtained from the manufacturer. They usually don't follow conventional sizing. When they don't, the overall diameter of the tire is usually part of the size. |

|

|

https://community.cartalk.com/t/driving-with-a-slightly-bulged-tire-is-dangerous/181365/31 |

|

|

|