|

B

arry's

Tire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Flatspotting There are 3 quite different things that are called "Flatspots".

|

|

Tires with Spot Wear: This is usually caused by brakes locking, but it can also be caused by skidding out. The tread is worn in one spot. Sometimes it is so severe that the plies will be exposed, like the example to the left. In theory, vehicles with ABS (antilock braking systems, which is most every vehicle today!) should not experience this wear, although it is still possible to get it if you skid out. As a general rule, the tire must be replaced. The exception is if no fabric is exposed and the vibration is tolerable. |

|

Irregularly Worn Tires: Sometimes tires do not wear evenly - that is, they wear irregularly. That produces high spots and low spots around the circumference of the tire. Some folks call the low spots "flatspots". I hope you can see why that is badly named: The spots have more wear. They are not just flat. The wear on the sample to the right is referred to as "diagonal wear" by folks in the know. Please note that there are other types of irregular wear that have been diagnosed as flatspots - incorrectly, in my opinion. This type of wear is caused by misalignment. Many times, there is a vibration, which is usually how this is discovered. The fix is to get an alignment. Unfortunately that doesn't fix the tire. Rotating the tire to another position can sometimes wear a new pattern on top of the old one and, perhaps improve the vibration. Unfortunately, this usually doesn't work. The alternative is to replace the tire. |

|

|

Out-of-Round Tires: OK, OK, the tire to the left is actually a flat tire - one with little or no inflation pressure - not a flatspotted tire. This is the best image I could come up with. This kind of flatspot does not photograph well. There are 2 different mechanisms going on here:

|

|

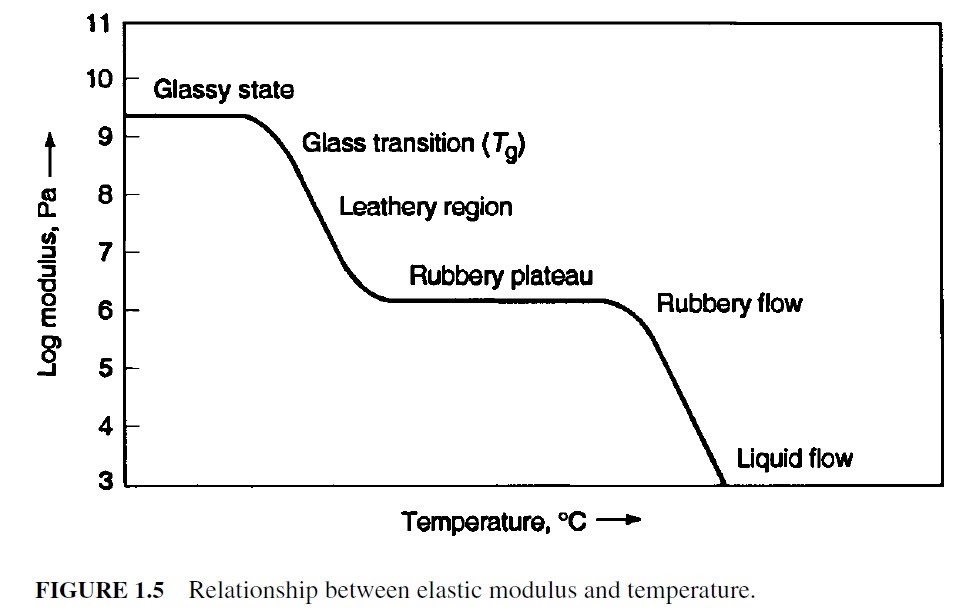

Glass Transition: Unlike what you may have learned, there are more than 3 states of matter (gas, liquid, and solid). One of those other states is a form of solid called "glassy". Amorphous materials - materials that don't have a crystalline structure - can transition back and forth between a glassy state and a viscous liquid state depending on the temperature. Rubber does this, but what is important here is polyamides also do it. Nylon is a polyamide.

For nylon, the glass transition temperature can be as low as 117ºF (47ºC). This is clearly within the range of operating conditions for tires. That means that once a tire rises above the glass transition temperature, the next time it cools it is going to take the shape it is in when it does so. Since this usually happens when the tire is at rest, that means a flatspot. The good news is that as soon as the tire returns to that temperature, it reverts back. The effect is temporary. |

|

|

So, you may ask, why don't tire manufacturers avoid using materials that have glass transition temperatures that are within the operating temperatures of tires. The answer is that they do - except for nylon. Nylon has this wonderful property of shrinking as the temperature increases, making it ideally suited in resisting centrifugal forces. So tire manufacturers have abandoned using nylon except for cap plies to cover the belts, thereby minimizing this effect. Plus there are ways to further minimize the effect. Here's the Wikipedia page on the subject of glass transitions. |

|

Mechanical Creep: This is where a material stretches (or shrinks) over time due to stress. Obviously the more the stress, the more the material stretches (shrinks). This is especially true of viscoelastic materials, such as rubber. So this kind of flatspot is caused by sitting too long in one spot. The result is that part of the tire is physically deformed - flatspotted - even after the tire is moved. This type of flatspot is more or less permanent. |

|

|

There are 3 ways to prevent this kind of flatspotting:

|

|

|