|

B arry's

Tire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Force and Moment: |

|

Tire engineers use the term "Force and Moment" to describe how tires generate cornering forces. But it's not just forces being generated, there are also torques (moments) generated. So, upfront, I will confess that this area of tires is a weak spot for me. The good news is that I don't have to go too deep into the subject for this article - certainly not deep enough to cause a problem. |

|

|

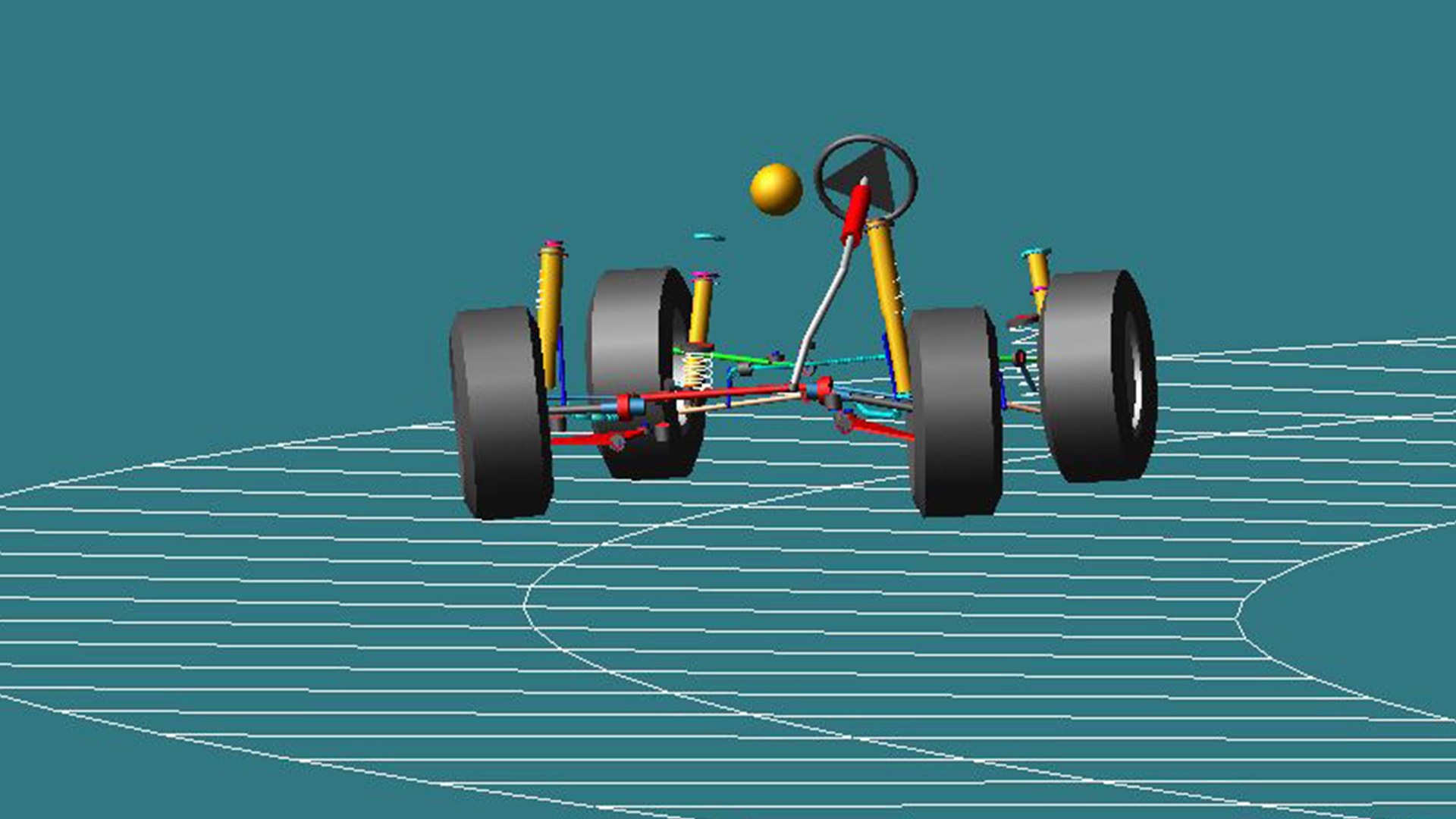

Nowadays all this is measured by machines purposefully built for this. Below is a YouTube video from MTS, showing one of their latest versions. |

|

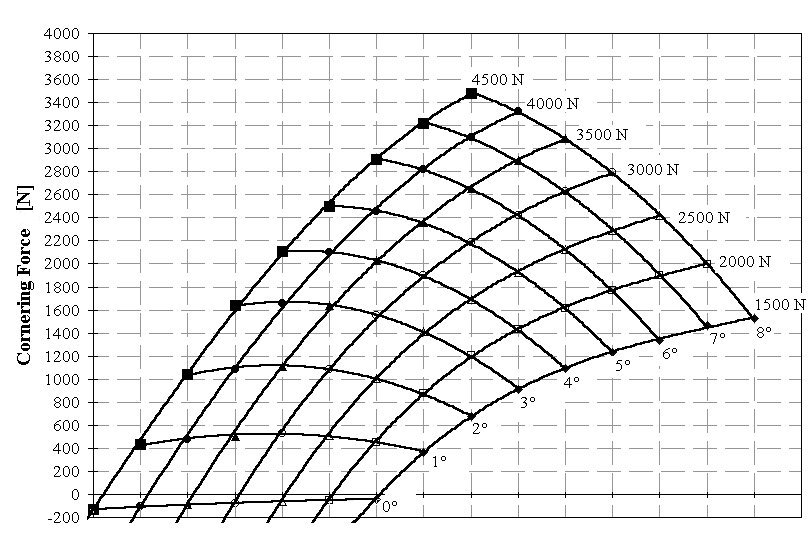

In the old days, the machines generated a series of graphs called "Carpet Plots". Nowadays, the output is a computer file - which can be used by a computer modeling program to describe how a vehicle would perform using that tire. This is both cheaper and faster. |

|

There are also ways to measure these on-vehicles or using a trailer. |

|

|

So why measure the Forces and Moments of tires? Handling! Handling is NOT how much cornering power a tire can generate. Handling is how it feels. What you want is something that feels predictable - and the more linear the carpet plots are, the more predictable the tire feels. |

|

Back when measuring F&M was done on less sophisticated machines, it was discovered that tires that are near the maximum load capacity had issues - AND that larger tires (load capacity-wise) had more linear carpet plots and therefore felt better. This occurred in the early 1980's. Car manufacturers subsequently started specifying larger tires. Please note that I think there have been 3 times car manufacturers increased the tire size. This one was the 2nd. The first was when radial tires were introduced (for looks!), and the last one was because of the Ford/Firestone tire recall debacle. |

|

|

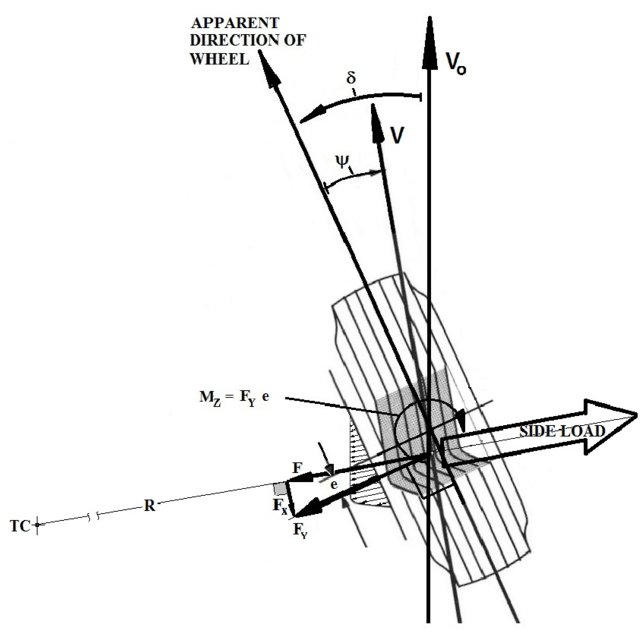

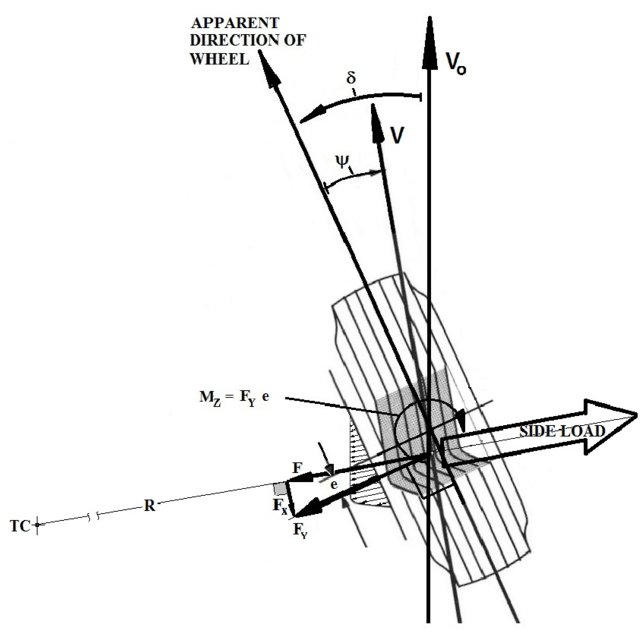

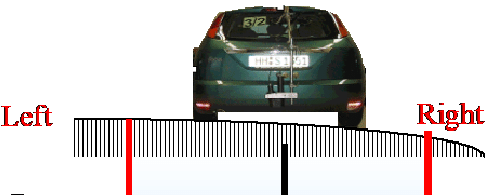

You saw this image at the beginning of this article, but there is one thing I want to notice: The footprint is off center from the pivot of the suspension. That offset generates a torque around that pivot point. We call that torque the "Aligning Torque", because the torque causes the steering wheel to return to the center (relaxed) position. But the tire's relaxed (zero force) position isn't when it is pointed straight ahead. Put another way, the tire, when pointed straight ahead generates a small side force - and we call that "Plysteer", because it's caused by the fact that the plies are layered - one going one direction, with the next going the other direction. In the tire industry, we call that "Angle Left" and "Angle Right", because of which hand the angles point upwards towards. |

|

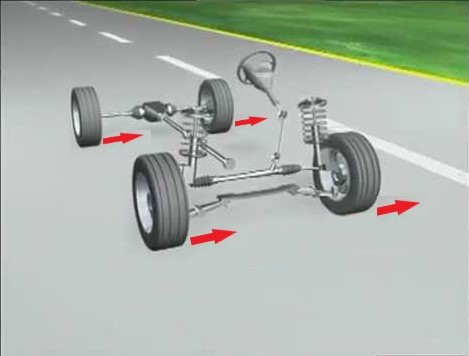

The odd thing about Plysteer is that when the steering wheel is pointed straight ahead, all 4 tires are pushing the car sideways, like in the illustration to the right. This causes the vehicle to "dogtrack". Some instead use the term "crabwalk". You'd think this would cause a problem, but the amount is much smaller than cornering forces, so a little bit of steering wheel input can compensate - so small the driver doesn't notice. |

|

|

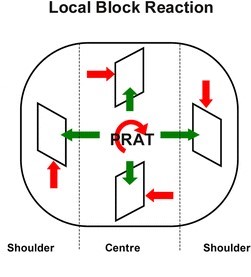

But there's more: Residual Aligning Torque! Because the tire is being distorted when rolling, a series of forces is generated in the footprint. Those forces cancel each other out - EXCEPT there's a torque left over. Usually Plysteer and Residual Aligning Torque are combined into a single term - PRAT - and handled as a single problem. Some car manufacturers deal with PRAT by specifying small values for tires that are supplied to them. But others deal with it by having different alignment values left-to-right on their vehicles - typically camber. |

|

But roads have a slight amount of crown in them so the water runs off. Some folks call this "road camber". For vehicles that drive on the right side of the road, the road crown counteracts PRAT. Side note: For vehicles that drive on the left side of the road, PRAT would ADD to the slight force trying to move the vehicle to the left. And this is what I don't understand: Why isn't this an issue in the UK, Australia, and Japan? I suspect it's because the values are so small - and perhaps this is why some car manufacturers have different alignment values - so they can adjust the alignment depending on the location of the vehicle. |

|

|

|

And lastly, one of the reasons I say I am weak in F&M is that I don't understand why some car manufacturers specify a low value of PRAT given that they must know that ordinary tires have high values of PRAT and their vehicles could get a bad reputation of sometimes having funny steering issues. I wonder if the reason there doesn't seem to be a problem is that the PRAT value has to be VERY high for there to be a problem and only rarely do tires get PRAT values that high. I wish I knew enough to explain this. |

|

|