|

B

arry's

T

ire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Match Mounting: Here's what you should get from this webpage:

|

|

What is Match Mounting? Nothing is perfectly round - and that includes both tires and wheels. But if you can match the high point of the tire to the low point of the wheel, the assembly will be "rounder". For wheels, it is pretty simple. They have runout, which is the variation of "out-of-roundness". You can measure it and find both the high spot and the low spot. Note: The photo to the left isn't the best way to measure wheel runout. The tire doesn't fit on the outside. It fits on the inside - and there are 2 places where the tire touches the wheel - and Yes! - they can be different! So the best way is to measure BOTH bead seat areas on the inside and average them. That means the tire has to be taken off!

|

|

Tires work slightly differently than wheels. It's called "Uniformity", and while "Out-of-Round" is part of this, there are also differences in stiffness around the circumference. This is also called "Force Variation". In order to measure tire uniformity, tire manufacturers use a TUG machine (Tire Uniformity Grader). To the right is a photo of one. The last time I checked (about 2005), these were $600,000 machines. It is pretty common for tire manufacturers to have several dozen of these at the end of the assembly line and they measure every tire produced. A TUG is much too expensive for a tire shop, so several companies have produced more affordable machines that mimic the same process - the most prominent is Hunter Engineering. They call their version "Road Force®" instead of force variation. |

|

|

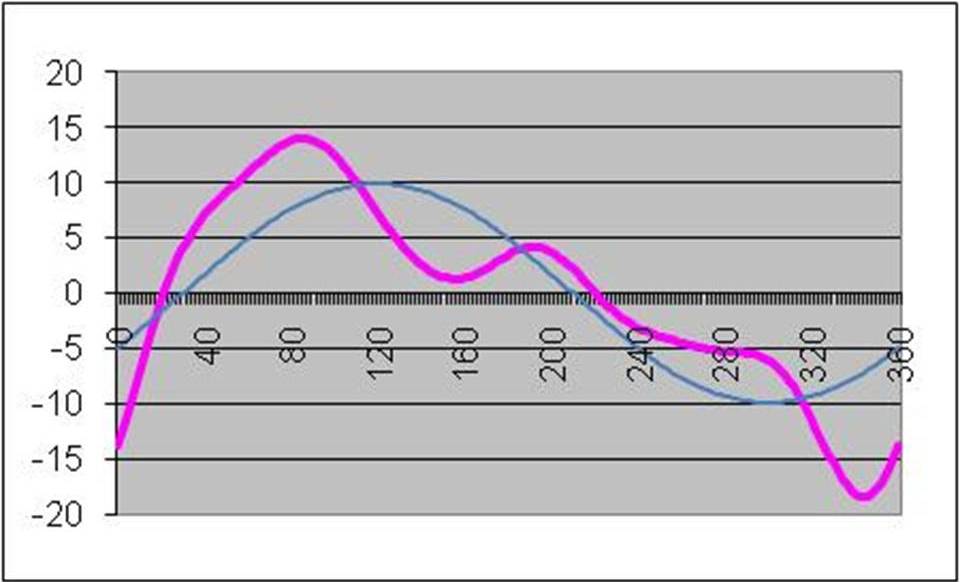

Basically, the uniformity of the tire is measured and the waveform received is broken down mathematically into once-per-revolution, twice-per revolution, three times-per revolution, etc. sine waves. The pink line is an example of a raw waveform with the blue line being the best fit first harmonic sine wave. We call this First Harmonic (R1H), but there are Second Harmonics (R2H), Third Harmonics (R3H), etc. The letters in parathesis are shortcuts for identification purposes. (R1H = Radial 1st Harmonic.) Please note that uniformity can also be measured in the side to side direction (Laterally), and at the footprint in the fore/aft direction (Tangentially). We use a similar notation (L1H), T1H), but these forces are generally not as large as the radial (up and down) forces and also don't cause as many issues. |

|

That's because vehicle suspensions are most sensitive to the radial first harmonic. Spring-Mass-Damper systems (which is what a vehicle suspension is!) have a resonant frequency - that is, there is a frequency where the movement is not damped out. In cars, that resonant frequency usually occurs in the 50 to 70 mph range (80 to 113 kph). Please note: Balance also works once-per-revolution. Static balance is in the radial direction and dynamic balance is in the lateral direction. Further, higher order harmonics - R2H, R3H, etc. - are usually much lower in value than the first harmonic. So even though they are felt at lower speeds (R2H: 25 to 35 mph (40 to 56 kph), R3H: 17 to 23 mph (27 to 37 kph), etc.), they are usually small enough to get lost in the "noise" from the road irregularities. |

|

|

For vehicle manufacturers, ride quality is very important, so they all match mount. To the right is a photo of one where the wheel runout low point is marked with a green sticker and the tire high point is marked with a long yellow sticker. This is a Ford - because of the shape of the tire sticker. BMW uses a white dot on the tire. Toyota uses a red dot. There is very little commonality as to what the vehicle manufacturers require. As a result there is also very little commonality in both wheel manufacturers and tire manufacturers. Did you notice the spot of green paint right above the long yellow sticker? I suspect that is how the tire manufacturer identified the high point. |

|

There used to be a time when many vehicle manufacturers required their wheel suppliers to put the valve hole at the low point. Vehicle manufacturers no longer do that - perhaps because both wheel manufacturing and tire manufacturing have improved and it's now difficult to make the valve hole without disturbing the runout of the wheel. So while you may see recommendations to match up the red dot on the tire with the valve hole, this is old advice and no longer applicable. Please note: It does no harm in doing this, but there is very likely no benefit. |

|

|

|