|

B

arry's

T

ire

Tech This is a series of articles on the technical aspects of tires, their care, and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Misalignment: |

What you should get from this page:

|

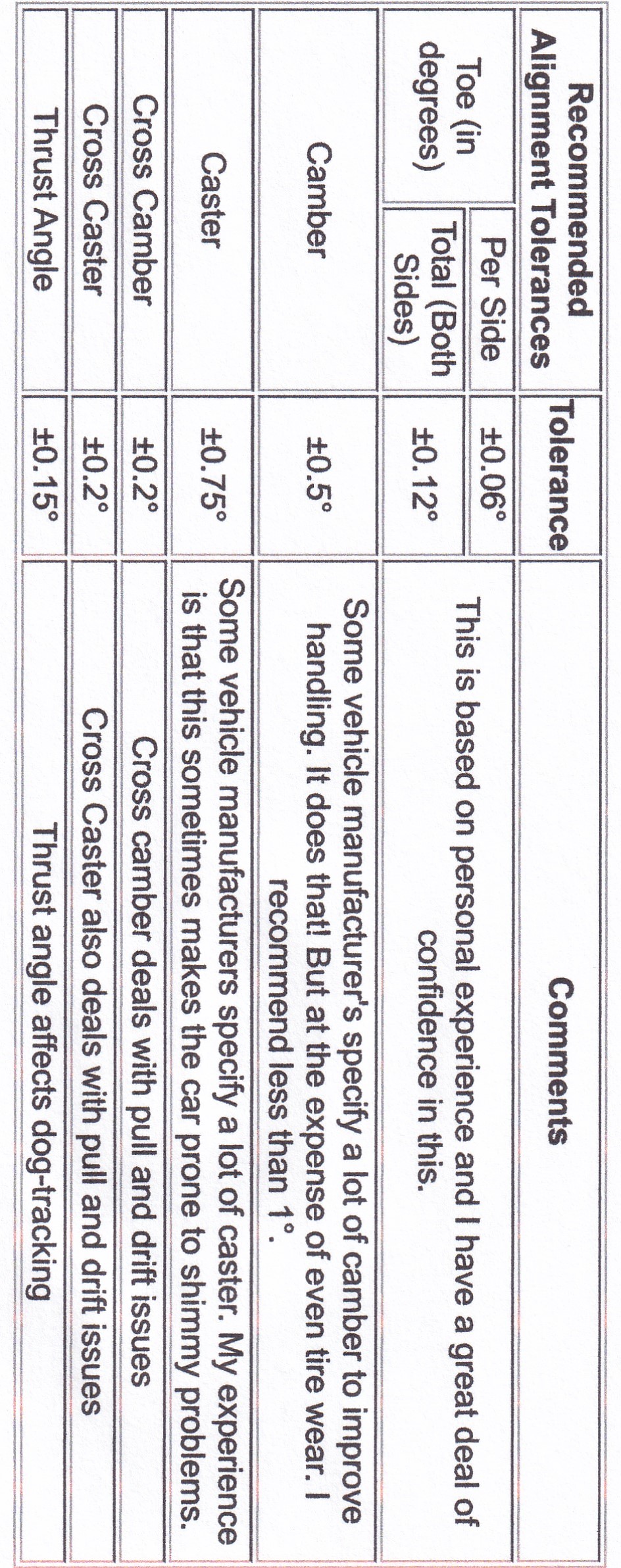

To aid in this, I've created the chart below. Right click on the chart, Open image in new tab, and once the new tab is open, print it out and take it with you. Please note that it is possible that after this was written, the tolerances might be changed - and likely to what I've published below.

|

|

Misalignment causes so many issues - and it shows up in so many different topics - that I am giving it its own page with the idea that I would reference this page instead of typing in the same exact words over and over again. Other people have done a much better job of explaining alignment than I can. Here are a few links to some of the better ones:

The biggest issue in alignment is toe. Toe not only causes tires to wear fast, but it also generates irregular and uneven wear (and therefore, vibrations and noise). |

|

BUT there is one thing that those links don't talk about: Caster adds to camber when turning. Caster causes the tires to lean more (or lean less) as the steering wheel is turned. Positive caster adds negative camber and negative caster adds positive camber. (Kind of backwards isn't it?) So I am of the opinion that a street car shouldn't have a lot of camber, but should have some caster. Fortunately, most alignment specs have enough caster (in my opinion) regardless of how much the camber spec is.

|

|

|

I am of the opinion that the published vehicle manufacturer's alignment specs are too wide - by half. In order to get good tire wear and avoid noise, the alignment has to be within the inner-half of the allowable range. |

|

Many years ago, I worked in an area where a major tire manufacturer dealt with consumer issues. Our rep to one of the Japanese vehicle manufacturers asked me to examine some tires that had some irregular wear on the outside shoulder of an All Terrain tire we were supplying. He forwarded some samples to me and I concurred with him: Alignment was the source of the problem. Needless to say, that did not go over very well with the vehicle manufacturer. |

|

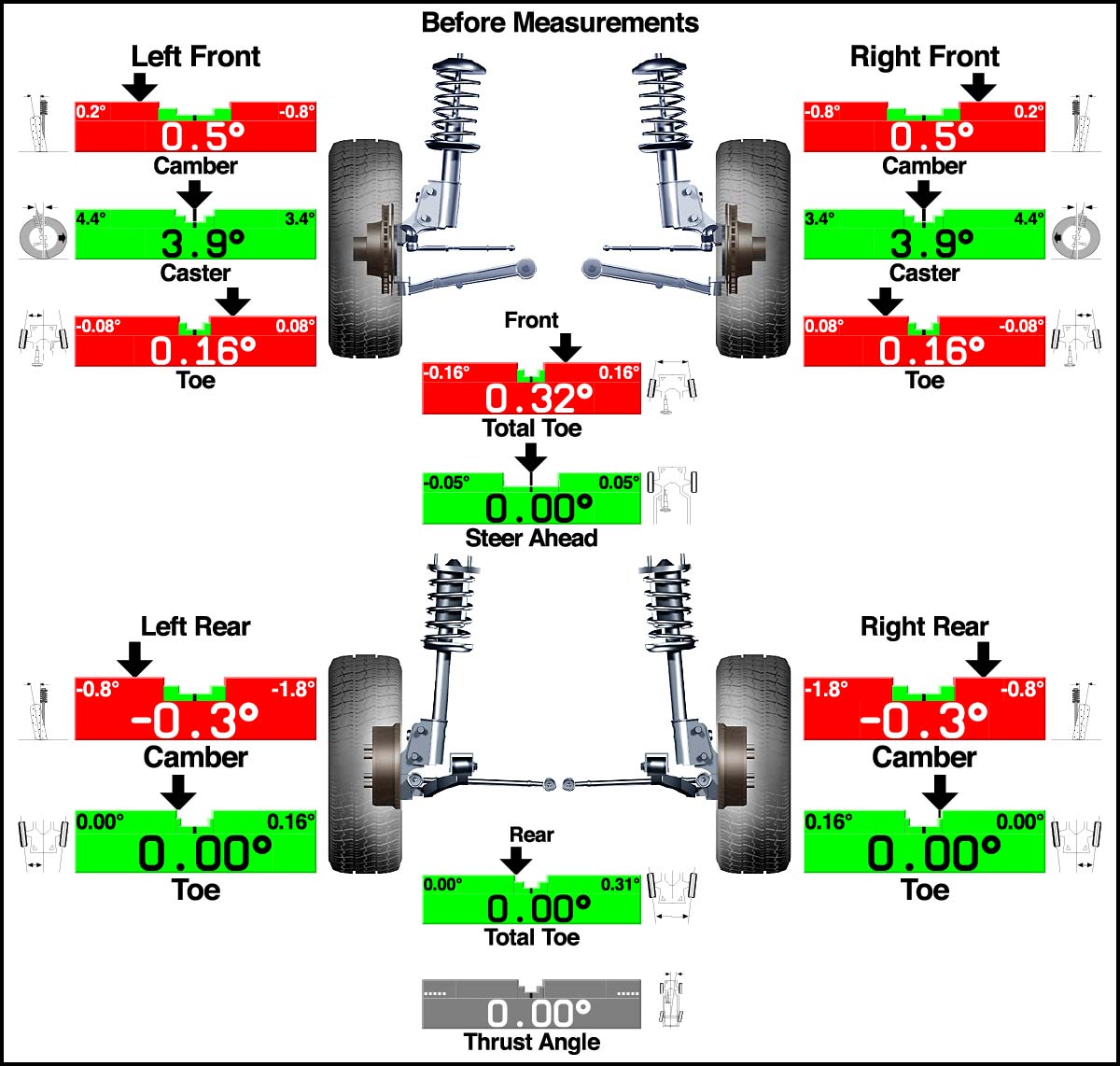

In order to provide data to support this position, we started asking vehicle dealers who called in to get authorization to replace tires to do an alignment and provide us with a copy of the "BEFORE" settings. Unfortunately, we didn't get a lot of copies, but there was one very interesting outcome: EVERY vehicle was either out of spec for toe or in the outer half of the tolerance for toe. NONE were near target value. |

|

|

Having spent many hours under my racecar to get the toe right, the tolerance they published seemed very wide. So I went to the library and looked up other vehicle manufacturer's tolerances for toe. I noticed that MOST of the tolerances were the same, BUT BMW's was half that - and so was the tolerance for several over-the-road trucks (18 wheeler type). Plus, those wide tolerances were the same as 40 years before when they put on bias ply tires - and I knew radial tires are more sensitive to toe than bias tires.

But I didn't have enough data to feel comfortable that I had identified the source of the problem. And for those who are curious, the misalignment issue was hotly debated within the vehicle manufacturer's organization. I don't know what happened, but the problem did go away. |

|

About a year later, a different vehicle manufacturer had a similar complaint on a completely different vehicle and with a completely different tire. We again tried to get the same "BEFORE" alignment values - and, again, not much data, BUT the very same thing: Every vehicle was, at best, in the outer half of the toe tolerance. So while I feel pretty confident about the toe tolerance, I admit it is based on very limited data. |

|

|

To add to this, I used to be the technical rep to a major vehicle manufacturer. Part of my job was to address tire wear and drift/pull issues their dealers were having. In the process, I found out that their assembly plants were having problems meeting the published alignment tolerances. The vehicle engineers I worked with were aware of this and while they wanted to tighten the alignment tolerances, they knew this wasn't going to happen. The management at the assembly plant wasn't going to allow that! The argument from plant management was that they weren't meeting the current spec, so why change it and make the plant look worse. They were successful with that argument. This is the basis on my opinion. |

|

Please note: This was (and is) not the only time a manufacturer wasn't able to meet their own internal tolerances (and I'm talking about more than vehicle manufacturers here). Side note: It takes corporate management to mandate that manufacturing tolerances will be set by the engineers - with appropriate data, of course - and not by plant management. Plant management is allowed to complain and point out the need for new equipment, but they shouldn't be allowed to set the specs. Disclaimer: It is possible that some time after this is written that the tolerances for alignment may be changed - and likely changed to what I published above. For this reason, it might be prudent to look at the current tolerances for your vehicle and see where they stack up. See the chart above. |

|

So how does a consumer go about getting a GOOD alignment? The alignment tech has to be willing to do the work that all this might entail. Not every tech is willing to do this. Some techs even go so far as to think that if the vehicle manufacturer didn't provide for adjustment, then they shouldn't (or can't) - opting for a "Toe and Go" approach. They are wrong! For this reason, I recommend that consumers ask BEFORE:

The consumer needs to be prepared to pay for those additional parts - and it is certainly reasonable to ask how much they cost BEFOREHAND. |

|

|

What if you have irregular wear and that's why you're getting an alignment? One of the problems with trying to fix irregular wear is that you can't undo the wear that has already taken place. You can't do anything to reverse the wear. Any new wear pattern will be on top of whatever is already there. So generally fixing the alignment only fixes the source of the irregular wear and prevents the tires from getting worse. Replacing the tires is needed to get rid of the irregular wear and the vibration/noise associated with that irregular wear . And that's not quite true. Sometimes rotating the tires will allow noisy tires to develop a different - and less noisy - wear pattern. But, this doesn't work very often. |

|

Irregular wear names: For some reason, many otherwise knowledgeable people seem to misidentify certain types of irregular wear - and therefore, the cause. This is particularly true for "Cupping". While it is true that cupping wear is caused by out-of-balance and out-of-round tire and wheel assemblies, as well as bad shocks, it is common for many people to misidentify other types of wear and call it cupping wear. This is because bias tires used to be really susceptible to cupping wear - AND - back then, tire balance issues, out-of-round conditions, and bad shocks were pretty common. |

|

Not only are radial tires less susceptible to cupping wear, but bad shocks, out-of-balance and out-of-round tires are much, much less common nowadays. What I am trying to say is to be aware that some folks have bought new shocks unnecessarily - and since vehicle alignment is usually part of the shock install, the problem could have been fixed with just the alignment. This is speculation on my part, because I have never been directly involved in such situations. |

|

|

To conclude: It is now common for vehicle manufacturers to NOT put adjustability for camber and caster into their suspensions. Unfortunately, over time car chassis sag, they get tweaked by accidents, and there is always metal fatigue.As a result there are many manufacturers of camber plates and eccentric bolts that can make adjustability possible. Needless to say, those aren't free, but there should be no excuse for not using them to fix a vehicle that has alignment issues! Insist on it! But the right way to do this is BEFORE the alignment, not after. Plus many alignment techs know it takes more time and effort, so they are reluctant to do this. It just makes sense if the alignment tech knows he is dealing with a discerning client. He may refuse to deal with such customers, but those that choose to do so, should be rewarded for their efforts. Be happy to pay for a job done well. |

|

|