|

B arry's

Tire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

|

|

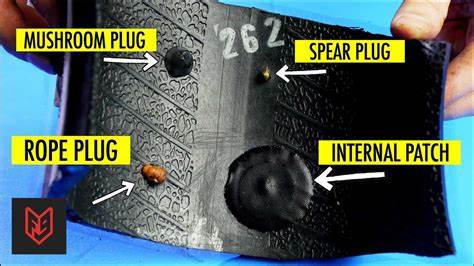

Repairing Tires: First, while I am not a fan of plug-only repairs, they are sooooo prevalent, I feel obligated to offer some tips to make the plug repairs more successful:

|

|

|

I'm going to divide the rest of this into three parts:

|

|

To the right is an image of a wallchart published by the US Tire Manufacturers Association (USTMA) covering the procedure to repair passenger and light truck tires. Do not bother to download this image, as it is not detailed enough to actually be read. Instead, buy the wallchart ($3.00) here: USTMA Publications

|

|

|

Summarizing:

|

|

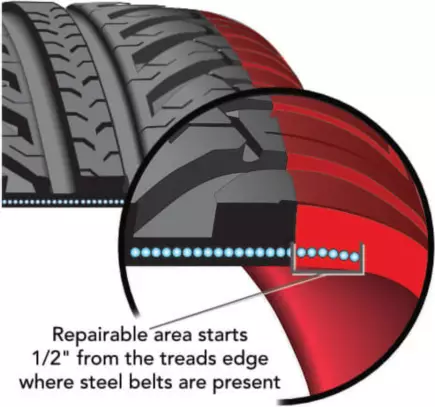

Why? The edges of the belts is the most highly stressed part of the tire and damage in that area has an elevated risk of a failure - very bad!!

The repair has to reinforce the area around the damage and prevent stuff from entering the damaged area. By itself a plug doesn't reinforce the damaged area and by itself a patch doesn't prevent stuff from entering the damaged area. The damaged area has to be reinforced. So no tube by itself. |

|

|

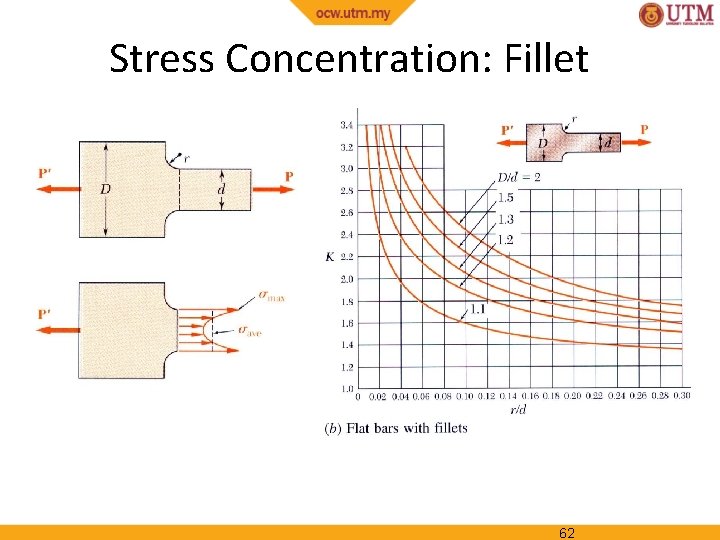

Why ream out the hole? Stress Concentration! Here's a link to a good explanation: Mechanical Booster: Stress Concentration Short Version: Sharp Corners = Bad! Rounded Corners = Better. A nail penetration is like a crack - it has at least 2 sharp corners. Plus, you need to be sure that there isn't anything in the hole when it gets plugged! |

|

So why not repair the sidewall? Because the sidewall goes through a complex motion as it goes through the footprint and repairs in that area tend not to hold up. Unfortunately they tend to fail at high speed - Very Bad!! |

|

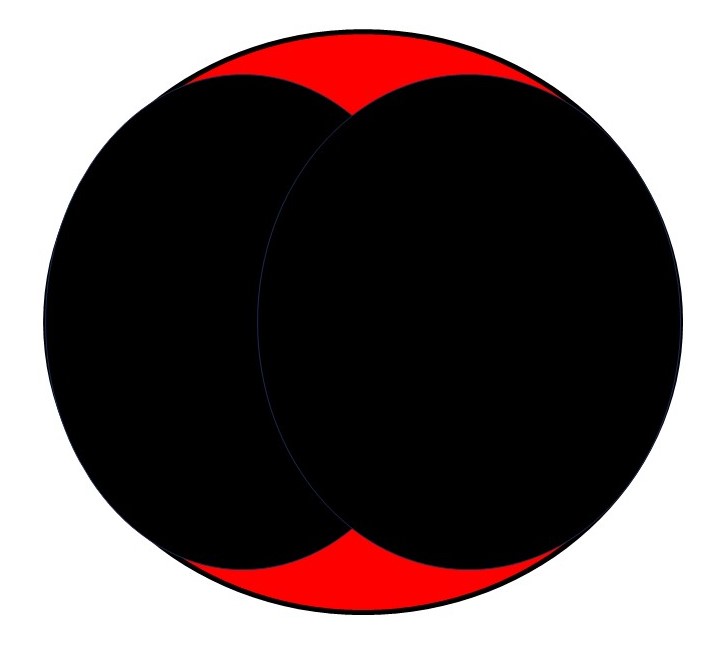

The thing that bothers me the most about plug-only repairs is illustrated below: To the top-right is a photo showing someone using a plug to repair a tire. Notice that the plug is doubled over. To the right that is what a doubled circular plug (distorted) would look like in the hole (exaggerated). Notice the red area, where the plug would have to deform in order to seal! That means there will be opportunities for a leak. |

|

|

Another thing about a plug only repair is that no one looks inside - and you might find something like this: That dust is the innerliner, which is supposed to hold the air in. Notice the abraded area just above the dust. By wearing through the innerliner, the tire doesn't hold air for very long! |

|

How many repairs can a tire have? Every time a tire is repaired, the risk goes up. Tire manufacturers are somewhat nervous about repaired tires - for 2 reasons:

As a result the USTMA says to contact the tire manufacturer - and tire manufacturers usually have a policy that repaired tires don't have a warranty! In other words, no one wants to be responsible for repaired tires, including those that actually do the repairs! So I am going to give you some guidelines. These guidelines are just that: Guidelines! Repair tires at your own risk!

|

|

|

What about speed ratings? Again, it's going to be difficult to get straight answers because of the legal liability. So more personal guidelines:

|

|

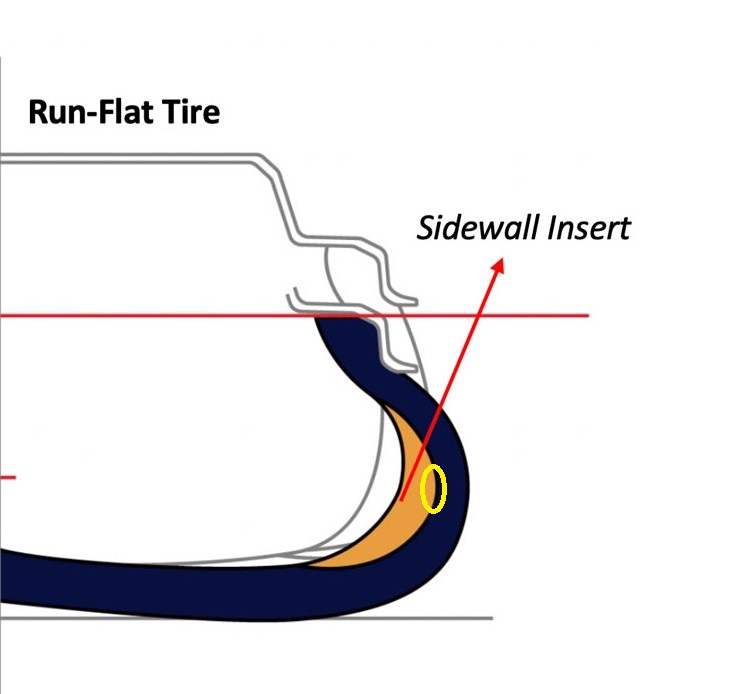

What about RunFlat tires? Here my webpage on RunFlat Tires: Barry's Tire Tech: RunFlat Tires Short Version: When operated without inflation pressure, RunFlat tires can develop a separation in the middle of the sidewall. (area circled in yellow) In a regular tire, you can see such a failure, but because of the thickness of the insert, you can not see this damage in a RunFlat tire. For this reason, some tire manufacturers do not authorize repairs on their RunFlat tires. They want you to replace the tire, fearing the RunFlat tire may have failed. Please note: tire manufacturers that DO authorize such repairs are merely accepting the risk - not that they are building a better tire. Below is a link to Tire Rack's webpage on the subject. Source: Tire Rack: Can RunFlat Tires be Repaired? |

|

|

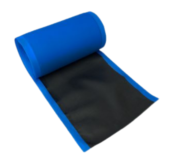

And now for something completely different: Section Repairs: This a type of repair that rarely gets talked about. Partially because it is only applicable to bias tires, partially because it is expensive to do. So this type of repair is done mainly on mining tires, particularly the big, expensive ones. Look at the size of that hole! Repairs like this take time and money to do. It just isn't cost effective to do them on small tires. |

|

|

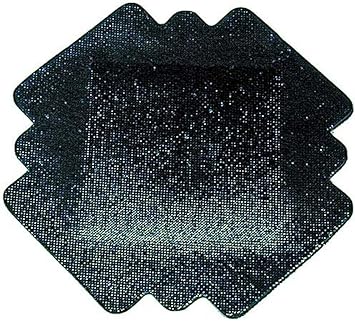

To the left is a section repair patch. Notice that it is several layers thick. Below that is a roll of tread rubber. The patch would go inside - reinforcing the damaged area - while the tread rubber would be used to fill the hole. |

|

Barry's Tire Tech - Main Page |