|

|

B arry's

Tire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Retreading: |

|

Retreads have an undeservedly bad reputation - partially because early retreads DID deserve it, but they no longer do - and partially because of a huge misunderstanding. Ya' see, many folks think that if they see a failed truck tire along the interstate, that it's a retread failure. But if you can see wire, then the carcass failed, not the retread. But the entire picture is that truck tires are routinely retreaded - many times (I've heard up to 6!!) and it is likely that the failed tire is a retread, it's just that the retread portion of the tire is not what failed. |

|

|

Further, at least in the US, all retreads have to meet the same DOT regulations new tires have to meet. That means the tire must have the letters "DOT" imprinted on the sidewall - and the obviously easy way to do that is to use tires that already have that marking and not to cover up that marking. Additionally, retreads have to meet FMVSS 117, which talks about what casings are not acceptable for retreading. Retreads also have to be marked with the retread plant code (starting April, 2025 it has to be 3 digits) and a date code (as of 2000 it has to be 4 digits in a week/week/year/year format). Editorial note: The above obviously does not apply to tires not used on US highways. Aircraft retreads have their own set of regulations. I am not familiar with those regulations and can not comment on them. |

|

Not all tires can be retreaded. Some tires are specifically designed to be retreaded - that is it is designed to be able to endure many, many miles of loaded service as well as be capable of being heated (cured) several times. Not every tire can do that. Typically truck and bus tires (TBR) - the over-the-road variety - and commercial aircraft tires are. Passenger car and light truck tires are generally not. Please note that I am not saying passenger car and light truck retreads are unsafe. I am saying that certain tires are designed to be retreaded and others are not. |

|

|

All potential retreads have to be inspected. The inspectors are looking for a good casing, so they have many reasons to reject the casing. Retreads have to be buffed to remove the excess rubber and to provide a clean and properly textured surface for the new rubber to adhere to. Please note: There are additional regulations on the use of retreads. Typically, they can't be used on the front positions of trucks and buses. Those regulations vary depending on locale. |

|

There are three methods tires get retreaded:

I'll talk about regrooving later. Please Note: The retread industry isn't very strict nor consistent when it comes to the use of the above terms. You will find different people use the terms differently than what I do. I've tried to be especially precise and I feel the need to warn readers about this problem. |

|

|

Cold Cap: While this is an old technique, recent innovations have made this method extremely popular and has almost completely transformed the retread industry. It consists of a precured slab of tread rubber - with the tread pattern already molded into the slab. See the image to the left. So this method is sometimes referred to as "Precure". Notice that the tread slab has a blunt edge (called a butt splice) and the tread slab has to be cut to length. Under the precured tread slab is a thin sheet of uncured rubber. |

|

Notice that the grooves in the tread pattern are not going to perfectly line up. That doesn't seem to be a problem, although I don't have first hand knowledge on that. In this method, not much heat is needed as the only thing that needs to be cured is that thin rubber layer under the tread rubber. This is the preferred method for retreading truck/bus tires as this is quick and the tire doesn't get a lot of heat history. While I don't know this for fact, my experience says that the rubber in precured treads can be quite different than what is used in molded rubber. I suspect that means a more dense and longer wearing rubber could be used. But a quick read of claims by retreaders using this technique don't make the claim of better mileage, so I am likely wrong. |

|

|

If a large fleet of trucks or buses is involved, the tire sizes are generally the same for the entire fleet and the retread plant can be set up fairly close to the truck/bus maintenance garage, making the whole process very effective financially. |

|

Hot Cap: A hot cap is just like a cold cap except the rubber is uncured and is put in a mold to get the tread pattern - sort of like regular tires. There are 2 ways the rubber is applied: As a slab or spiraled on as a thin strip (See the photo to the right). Then it is put in a mold that is basically a ring, This is the way most aircraft tires are retreaded. If the rubber is spiraled on, this method has the advantage of not having a splice that could open up under extreme shear stress, such as a landing. But it has the disadvantage of adding heat history to the tire - which for aircraft tires isn't a big deal. However, it is a bigger deal for truck/bus tires. |

|

|

Remold: As the name implies, this method is very close to what happens during the curing of new tires. The retread is buffed not only to remove the tread, but it also lightly buff off the sidewalls - enough to remove all the markings. The finished retread looks very much like a new tire. This is the preferred method of retreading passenger car tires, because the retreader wants HIS name on the sidewall, not the name of the casing manufacturer. Plus, this allows the retreader to use many different brands for casings. To the left is a remolded tractor tire. Notice that the mold goes all the way down the sidewalls. A Hot Recap would only go down to the sidewall/tread junction. |

|

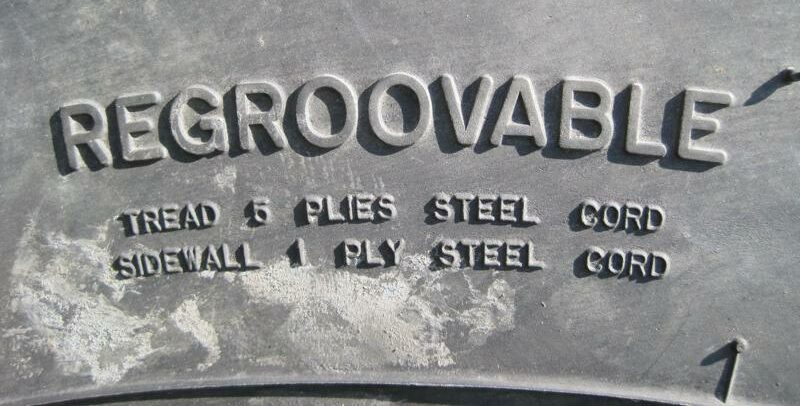

Regrooving: This is not actually a retreading process. The only reason I am talking about it in this article is that it is frequently associated with and done by retreaders. As the name implies, it is taking a tire and cutting new grooves into the tire. In general, the tire has to be designed for this - by being made with thicker tread rubber. Regrooving a tire not designed with this extra rubber could result in exposing the fabric (belt?) - not good! Many Truck/Bus tires are regroovable - and it will say so on the sidewall. Why not make the tire with deeper grooves to begin with? Because deeper treaded tires wear faster and even though the net is more miles before wear out, using the regrooving method adds more miles than a deeper tread depth. The tool used is a heated U or V shaped blade, like to the right. (Please note that these tools are also used when racing on dirt to get a sharp edge.) |

|

|

Why don't they retread passenger car and light truck tires? Well, they do, but the cost of doing the retread is almost as much as making a new tire from scratch. Further, passenger car and light truck tires come in a wide variety of sizes - too many to be worth making equipment for all of them. Plus there is the problem of legal liability. Ya' see, whether we like it of not, accidents happen and some of those result in lawsuits. Since the profit margin on retreaded car tires is so low, the retreader is especially vulnerable. As a result, snow tires and off-road tires are the most likely tread patterns. |