|

Barry's

Tire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Rubber Chemistry #2: Machinery used to Process Rubber for Tires: This is the second in a series of articles about the rubber chemistry of tires. I am NOT a rubber chemist and my knowledge is rather limited, so I could use some help. If you are a rubber chemist, please contact me at the email address above.

|

|

Mills: One of the most fundamental pieces of machinery involved in rubber processing is a mill. It consists of 2 rollers mounted horizontally and sometimes called "Horizontal Mills" to distinguish them from other configurations that are used for different purposes and usually have different names. I'll talk about those below. There is small gap between the rolls called the nip. Both rollers are powered, but the front roller is geared to rotate at a slightly faster speed, because the rubber will cling to the faster roller and the operator wants the rubber attached to the front roller so he can control it. Mills come in a variety of sizes, but most tire factories use fairly large ones - up to 60" wide. The one pictured to the left is a lab mill, used for small batches of rubber. This type of mill is useful when developing new rubber compounds and for quality purposes. |

|

These pieces of machinery are very dangerous as a person could get pulled into the nip. This was the source of many fatalities in the past and continues to this day, in spite of safety equipment. To the left is a video of a mill being operated. The first part of the video shows the mill with mostly broken down raw rubber. Notice the amber color. Be aware that this video shows a mill WITHOUT safety features to prevent personal injury. A few seconds into the video, the operator uses a knife to cut a slice of rubber that he rolls up, eventually cutting the ribbon of rubber, and carrying it away. |

|

At about 45 seconds, the video shifts to mostly processed rubber (because it's black!) and the operator adds a powder from a bag. This is called "Open Mill Mixing" and it is the way rubber used to be mixed way back in time. I suspect this method was used in Firestone's Decatur plant - the one involved in the Ford/Firestone controversy in the summer of 2000. I go into much more detail about the controversy here: Barry's Tire Tech - The Ford/Firestone Controversy Open mill mixing is largely gone from tire factories. However, horizontal mills are used to feed calendars and extruders. |

|

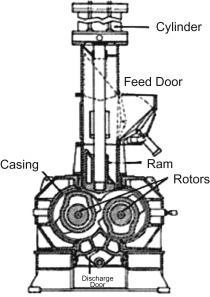

Banbury: A banbury is an internal mixer and similar to the mill, it has 2 rollers, but these are inside a housing and are shaped to shred the rubber. It is named after the man who invented it - Fernley H. Banbury - in 1916. They come in a variety of sizes, just like mills. The ones used in the factory are 4 stories tall, with the actual mixing chamber on the second floor. The opening into the mixer is on the 3rd floor, and a normal mill is on the first floor below the discharge door. These machines are much, much safer than a mill, and have almost completely replaced mills as the mixers. |

|

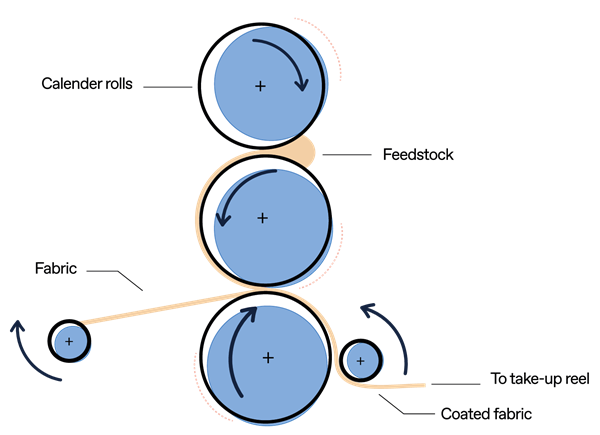

Calendars: Calendars are just like mills except the rollers are not positioned horizontally. Some are stacked vertically, which allows a thin sheet of rubber to be made, which can be pulled off the roller. |

|

|

To the left is an illustration of how a 3 roll calendar can produce rubber coated fabric. - HOWEVER, the fabric is only coated on one side! To coat the other side, the fabric has to be run through twice. - OR - |

|

A fourth roller can be added to feed another sheet of rubber, and the fabric can be coated in a single pass. A common configuration is called a Z Calendar, because the rolls are mounted in the shape of the letter "Z" (sort of!). Calendars are always fed by a mill. The mill heats up the rubber and mixes it some more. Frequently there is a conveyor where a continuous ribbon of rubber can be transported to the appropriate spot in the calendar. |

|

|

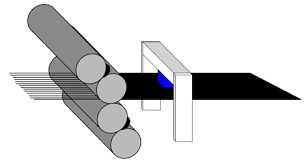

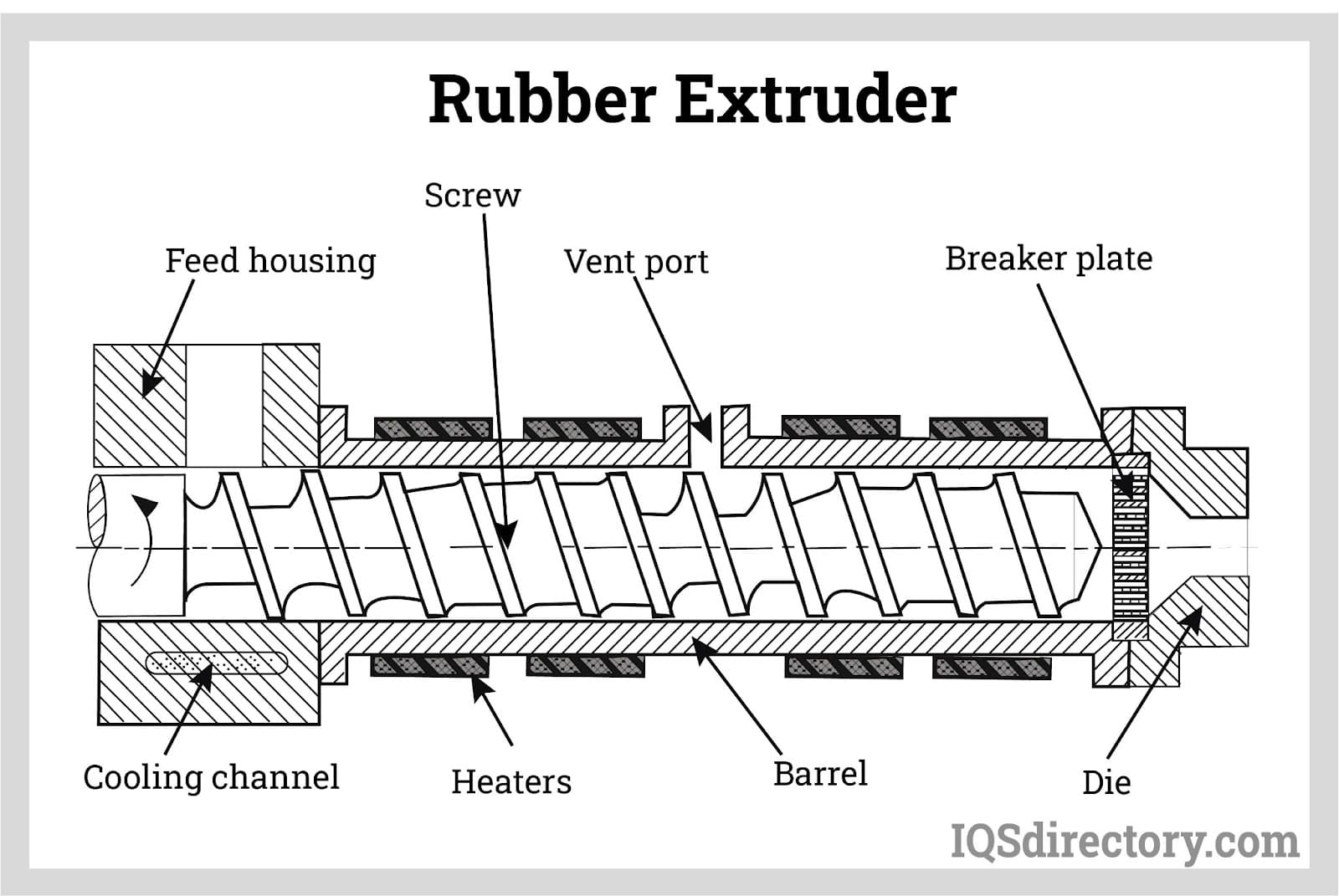

Extruders/Tubers: An extruder is a machine with a screw inside a housing that pushes rubber through a die. It is much like a meat grinder, except there is a gap between the screw blades and the die. Early versions of these extruders had a type of die that created a tube and the name "Tuber" stuck. I'll refer to these as tubers from this point forward as it is what I have always called them. A tuber is used to make shaped rubber slabs. Most frequently they make tread rubber because the shape needed is fairly complex and far from uniform. It is not uncommon for several tubers to be linked together so a rubber slab with different rubber compounds can be made as a single piece - like for both the tread and the sidewall.

|

|

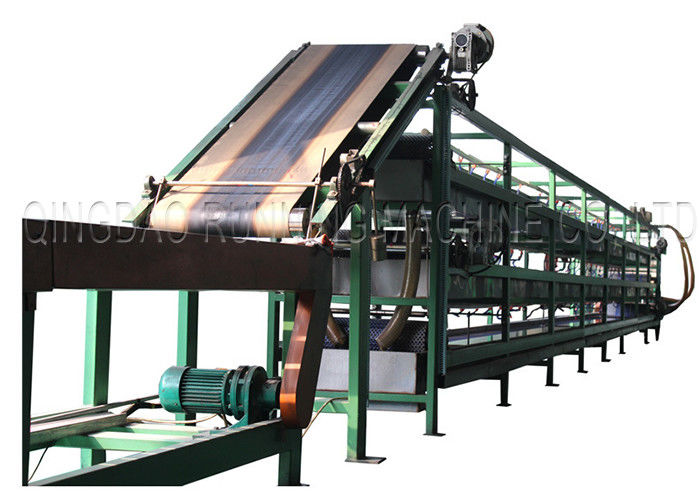

There are other pieces of equipment also involved with rubber processing, but some are usually involved with transporting or storing. Here are some not involved with storage and transporting. Festoon: a device at the end of a calendar, especially a fabric calendar, that allows the fabric to cool while under tension. Wig-wag: A device after a banbury that allows the rubber to cool after it is stripped off the mill. It's called that because the machine wig-wags back and forth when unloading the rubber onto a skid. Cooling Tunnel (and there are various names for this thing): A LONG conveyor line immediately after the extrusion head, where the extrusion is drenched with cooled water. It's long because rubber is an excellent insulator of heat, and it takes a long time for rubber to cool. And you want the rubber cooled so that when you cut it to length it doesn't shrink ( except it does shrink because the extrusion is PULLED through the cooling tunnel!!) Please note the device to the right is a cooling tunnel, but without all the shields to prevent water spillage. |

|

|

|