|

B

arry's

T

ire

T

ech

This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Wheels, Rims, and Spiders! OH MY!: |

|

It's time I talked about those other things that make tires work - Rims. OK, before everyone has a conniption - The difference between a rim and a wheel is this: A rim is the hoop shaped part that a tire is mounted on. See an example to the right: |

|

|

In addition to the rim a wheel also a "spider". The spider is the part of the wheel that connects the rim with the hub - like to the left. Yeah, I know that one doesn't look like a spider, but sometimes it does and that's what I call it. Other words are also used to describe this thing - disc, center section, etc. Normally, the spider and the rim are integrated into the same part. But as demonstrated above, that isn't always so. |

|

Further, sometimes there isn't a spider at all! Here's an example: Notice the tabs holding the rim onto the hub. This is the way they did things in the past. (OK, OK, the hub on this truck is sometimes called a spider. But sometimes it's called a wheel. Confusing? You betcha!) I hope it's now obvious why most tire people talk about rims and not wheels: The rim is an important part from the tire's perspective. The rest of the wheel - not so much! |

|

|

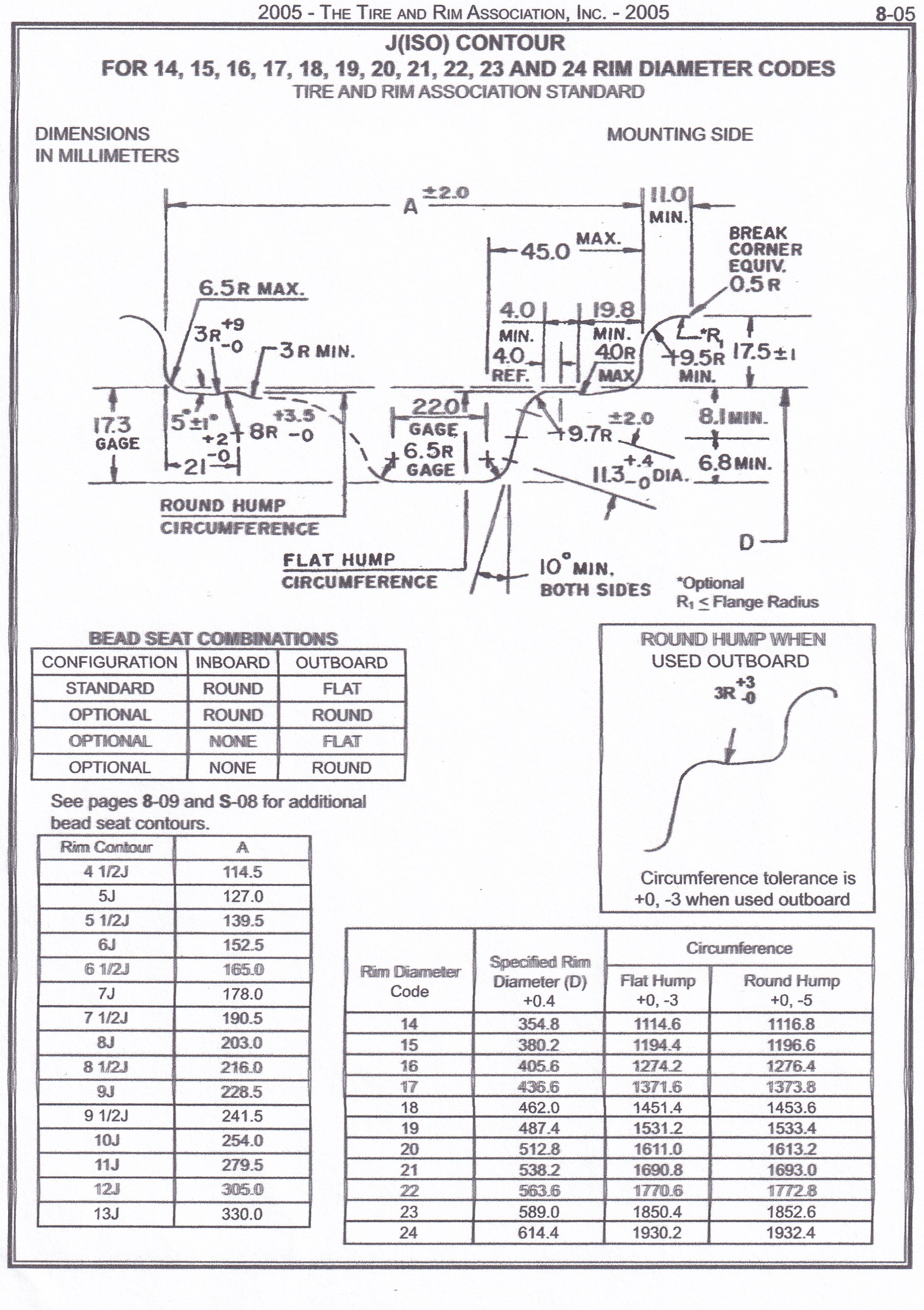

In order to make the rims compatible with tires, there has to be some kind of cooperation between the tire manufacturers and the rim (wheel) manufacturers. That's where tire standardizing organizations come in. I cover those here: Barry's Tire Tech - Tire Standardizing Organizations Among the things they publish are the contours of rims - but they only specify that part of the rim that affects the tire. To the left is a sample page from the 2005 Tire and Rim Association yearbook. First, note that the dimensions are in metric units even though the rim diameters are called out in even inch increments. They made that transition decades ago. (Some standards in English units have been grandfathered in.) Also note that the rim diameters aren't EXACTLY in even inches. For example a 17" rim is 436.6mm (17.189") Also note that not all the diameters are larger than the indicated dimension. Some are smaller. I do not know why that is. Further, the actual diameter is different for different kinds of tires. For example, a 15" car wheel is supposed to be 380.2mm (14.968"), while a 15" motorcycle wheel is supposed to be 15.080". That means that putting a 15" car tire on a 15" motorcycle wheel involves stretching the bead, making it possible to break the bead in the process - very dangerous! |

|

But I do know that the reason almost everyone uses even inch increments is historical. The first organization was founded in 1903 - and they were American and used English units. The other important thing is that different kinds of tires take different kinds of rims and each has its own standard. They distinguish those differences by using letters after the rim width. For example, a passenger car tire might fit on a 8.0JJ rim, but will not fit on an 8.00TG rim.

|

|

|

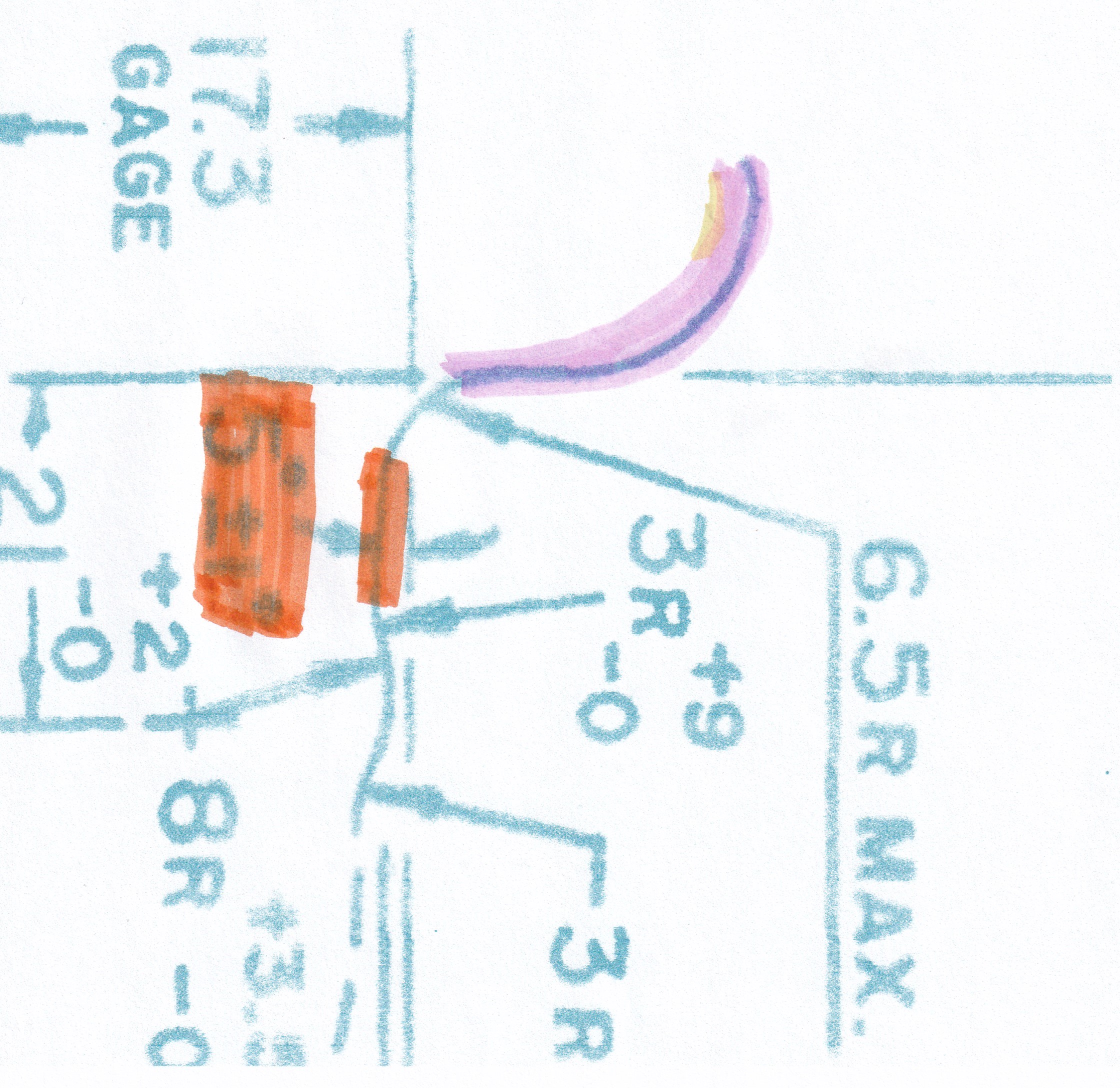

Let's look a little closer at the detail: Some nomenclature: I've highlighted the "flange" in pink, and the "bead flat" in orange and the space in between is called the "bead heel". I've also highlighted that the bead flat is tapered 5°.

Notice the "safety hump" just beyond the orange bead flat. That's to reduce the possibility of the tire being unseated, especially when the tire is low on air. It's the safety hump that causes that "Pop" when mounting the tire on the rim. That's also why mounting lube is important! |

|

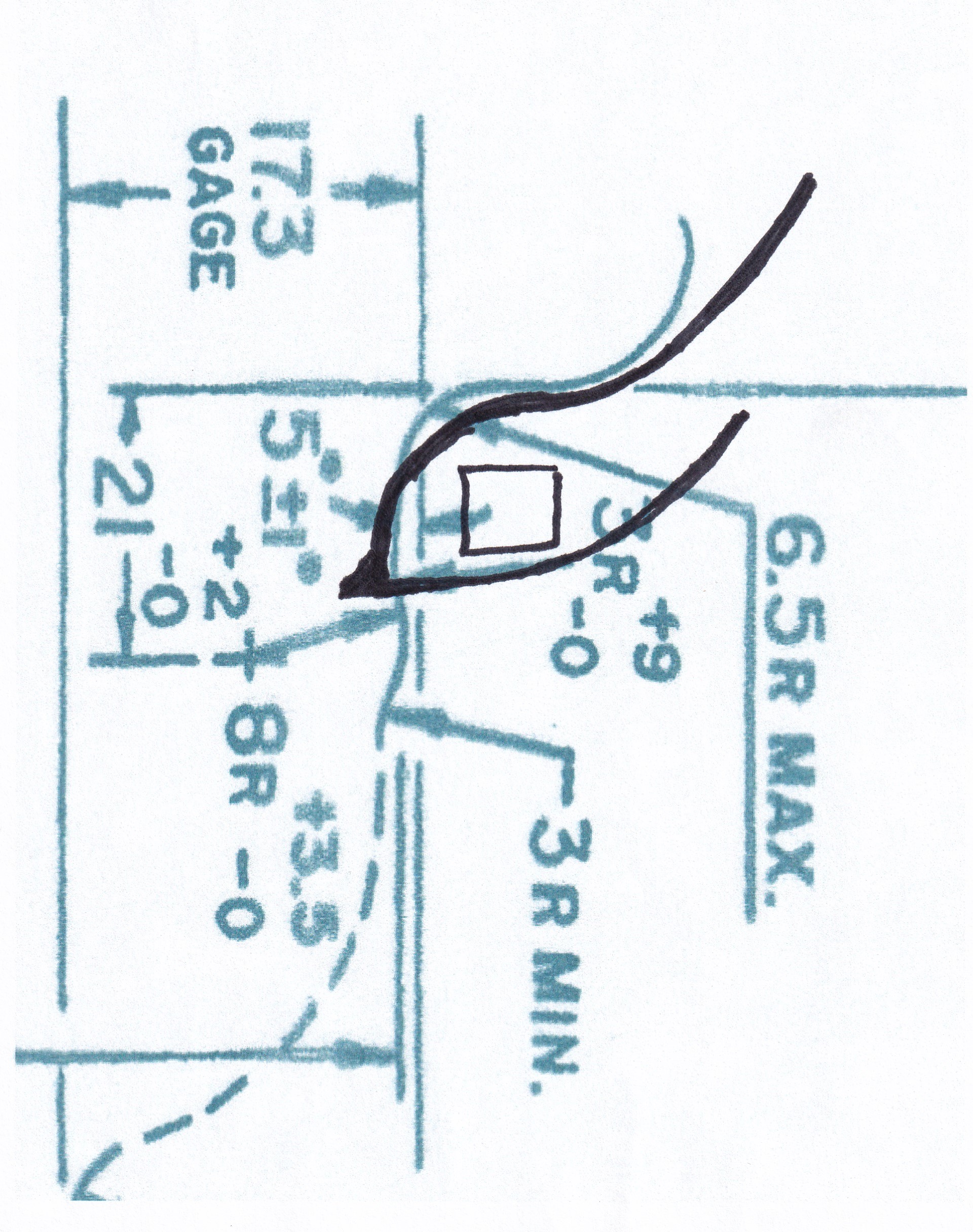

This is the same area as above, but I've added (in black) the way the tire bead would sit on the rim. (Please note, I've exaggerated the differences.) Notice that the bead is smaller in diameter (meaning an inference fit!), the tire bead taper is MORE than 5°, and the bead toe has a triangular shaped rubber ending. Every tire manufacturer does this differently and they don't all use all of those features. I hope it is obvious that the tire sealing takes place on the bead flat, not along the flange. Notice that the bead heel has a larger radius than the rim, so there is a gap between the bead and the rim at that location. This is intentional, to make sure the bead fully seats against the flange. And I hope it is obvious why we tire folk refer to the bead as having a toe and a heel. |

|

|

To the left is an old style rim known as a "Split Ring" (sometimes called "Split Rim".) Notice the split in the flange at about 90°. That is intentional. It allows the separate flange ring to be buttonhooked over the rim with the tire bead preventing the spilt flange from coming off - the split flange ring being slightly smaller in diameter than the place where it seats. There were several variations of this. But from time to time, one of those flange rings doesn't seat properly - especially if the ring is old and worn - and the flange can suddenly and explosively come off. Many people have been fatally injured - which is why these types of wheels aren't produced any more. (But old, rusted assemblies still exist! Be careful if you encounter one of those!) |

|

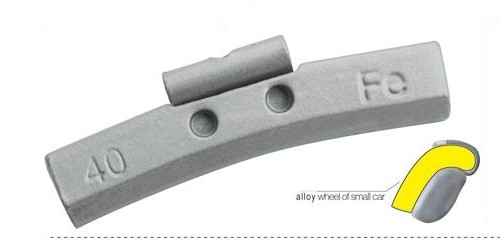

The last item to cover is balance weights. To the right is part of a chart showing the detail of one of the types of balance weights available.

Here is the whole chart. There are so many because there are so many different flange configurations. That part of the rim has never been specified by the tire standardizing organizations, but because rims used to be manufactured out of hoops of sheet steel, all the rim flanges had more or less than same contour where the weight would go. With the advent of alloy wheels, many different configurations of the face of the flange came into existence. These were later standardized, but not before there were 8 different configurations. (9 if you count versions where clip-on weights can not be used.) |

|

|

But some wheels don't have flanges that can use clip-on weights, so they use tape-on weights. These come in several styles. Some are designed to clear the brake parts, so they are thin. They also can be put behind the wheel spokes. But this configuration requires more weight, because of the smaller diameter and being closer to the centerline of the wheel. |

|

Update: Mar, 2024 I forgot to include a chart showing an application chart. Here's one that covers 2005 to 2018 US vehicles. |

|

|

|