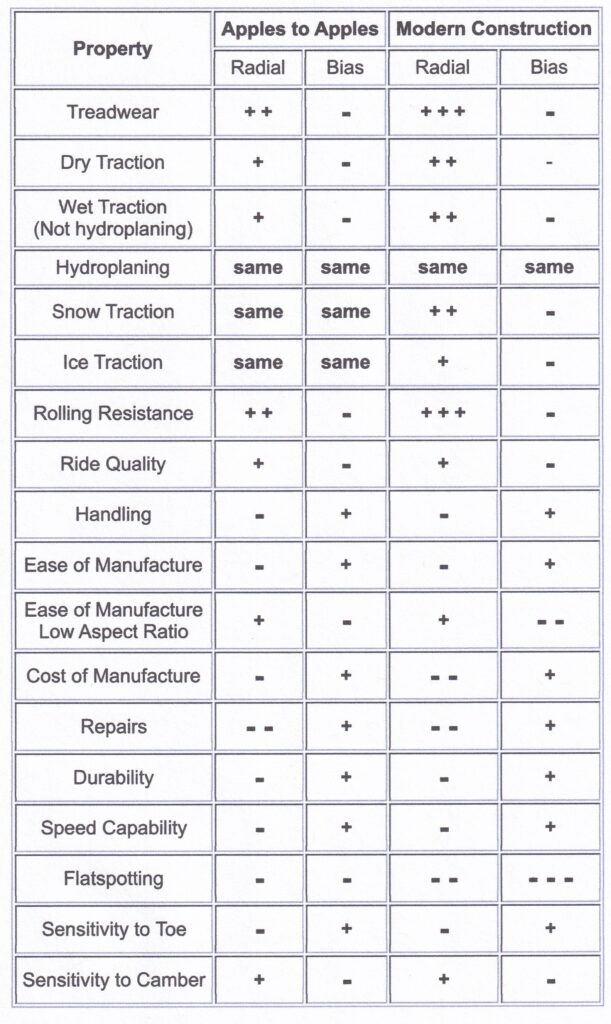

This article is going to compare bias ply tires with radials. While I will be referencing passenger car tires, the comparison would apply to any type of tire. There’s a summary at the bottom of the page, but read the introductory paragraphs first. They explain how I am organizing this.

Everyone needs to be aware that each of the properties listed below can have a wide range of values. It is quite possible to design a tire of one type to exceed the other type in a certain property just by careful selection of materials and design elements. Hydroplaning is one such property as hydroplaning is almost exclusively about the tread pattern – grooves and such.

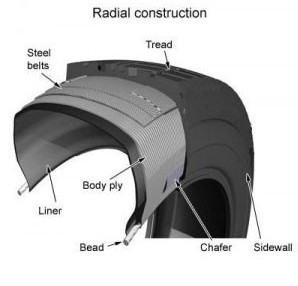

Modern radial passenger car tires have a steel belt.

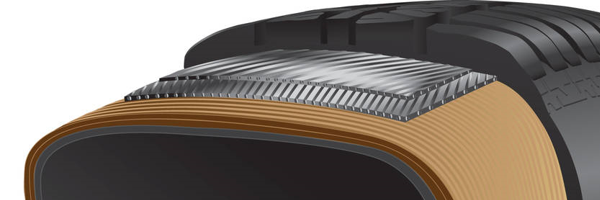

A belt is at least 2 plies of some sort of fabric under the tread, about the same width as the tread, with the strands oriented at a slight angle to circumferential. 15º is typical.

Radial tires need that belt because the only other thing holding the tire together circumferentially is rubber, which is fairly weak.

After trying belts made of various materials including the same fabric as the body plies, the industry has settled on steel wire.

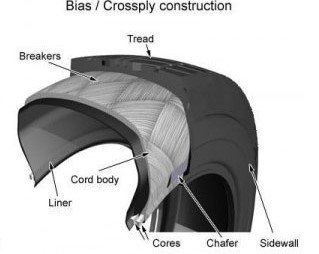

A bias ply tire doesn’t have a belt. If it did it would be called a bias belted tire, which has a combination of the best and the worst properties of both worlds!

I will not be comparing bias belted tires as you hardly see these nowadays.

Sometimes bias tires have breakers, which are similar to belts except that breakers have the same angle as the body plies. Breakers are usually the same fabric as the body plies, but occasionally other materials are used, such as steel wire. For the purposes of this article, the comparison will be to bias tires without breakers.

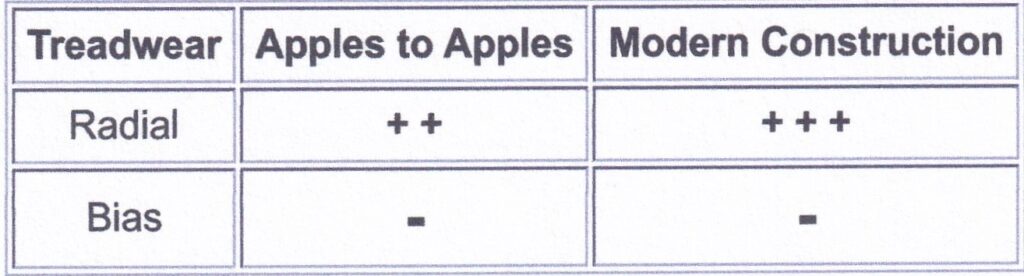

This is not going to be a completely apples to apples comparison as I am going to compare steel belted radial tires to bias ply tires without breakers. There are even more differences in modern tires. Radials are usually made of polyester body plies, steel belts, and if they have them, nylon cap plies. I am not including cap plies in any of the comparisons.

By contrast, bias ply passenger car tires – when they are made (Rarely!!) – would have nylon body plies. So I am going to make 2 comparisons:

An apples-to-apples comparison (same materials, except for the steel belt in the radial), which I am going to call the “Apples” Comparison, and a comparison to the way modern tires are built, which I will call the “Modern” Comparison.

Update July, 2025:

It has been pointed out that I should address Bias Belted tires.

There are 2 ways to do BB tires.

- On bias tire equipment. Here the belt is only at a bit of a different angle than the body plies. The net effect is that the belt is less effective – so whatever I say below about the effect the belt has, would be diminished in a BB tire.

- On radial tire equipment. Here the belt angle is substantially different than the body plies. The effect the belt would have is virtually the same as in a radial belted tire. Which doesn’t make sense to do as you only gain a stiffer, more responsive tire – and you can do that in a radial tire, soooooo??

OK, so here goes!

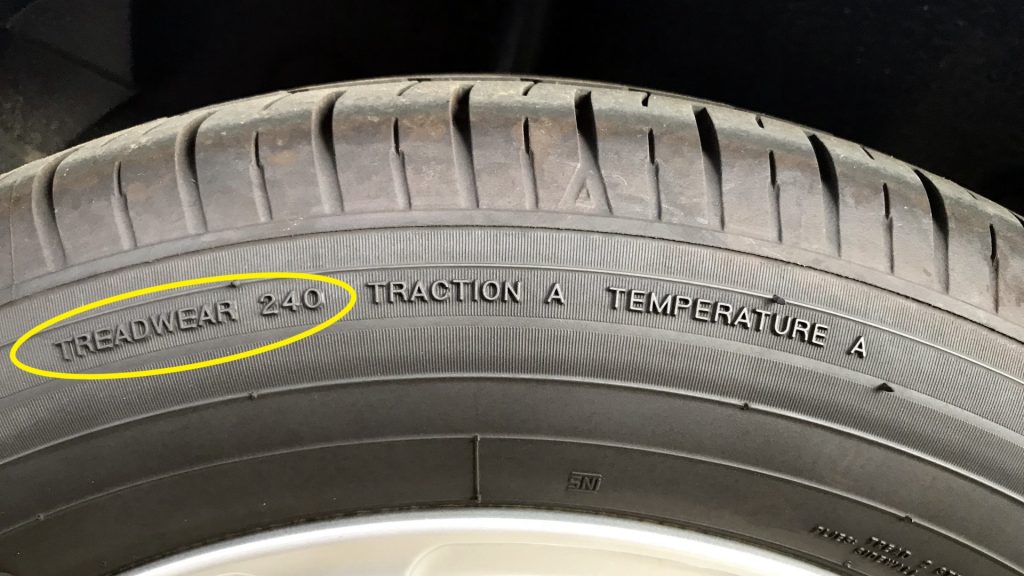

Treadwear:

This is where the radial really excels. That belt really stiffens the tread area, so the tread rubber wears very slowly compared to a bias tire. This is especially true for the modern comparison as the modern radial can use a much longer wearing tread compound than the by ias tire

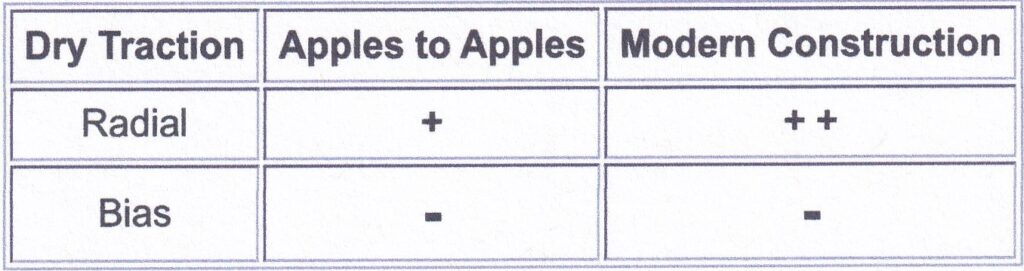

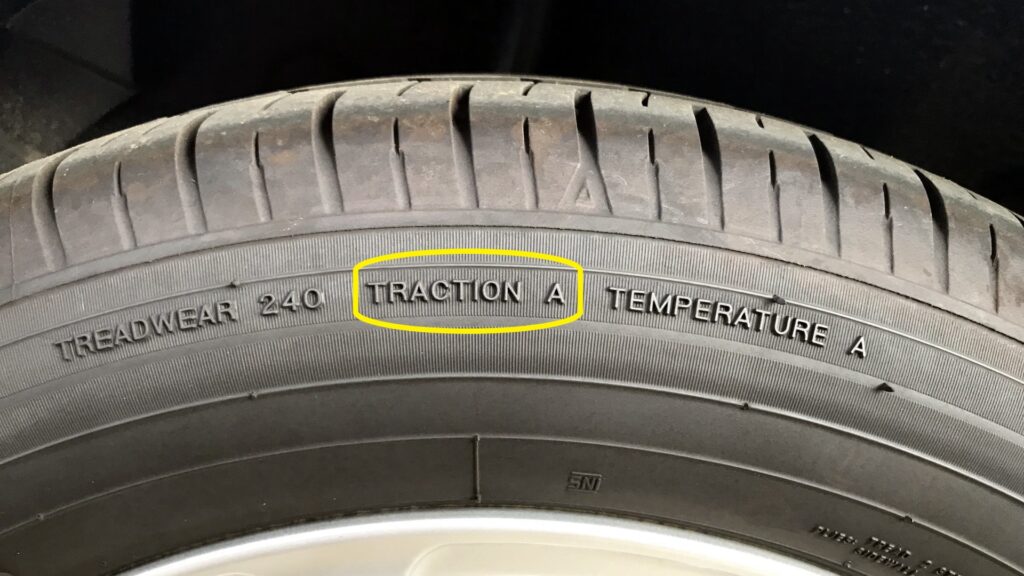

Dry Traction:

That stiffening belt works here as well, just not as much.

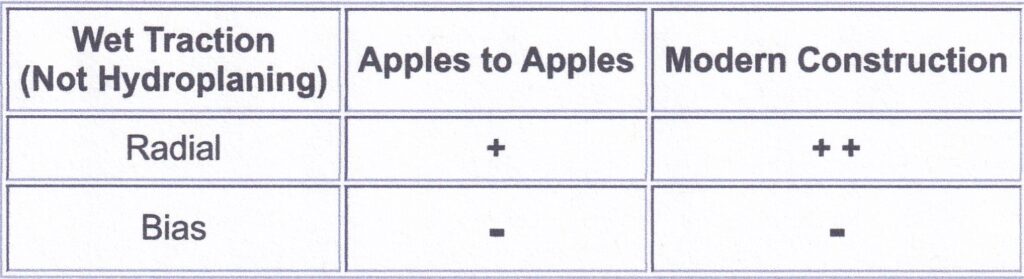

Wet Traction (Not Hydroplaning):

This follows dry traction as the tire thinks it is on a slightly more slippery surface. I will deal with the water surface tension (hydroplaning) next.

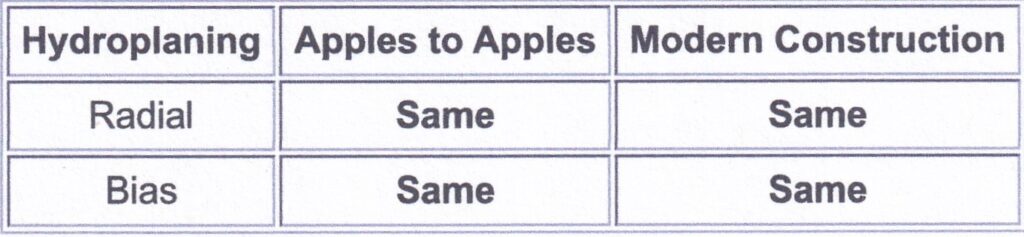

Hydroplaning:

That stiffening belt doesn’t really affect things as hydroplaning is more affected by tread pattern, water depth, vehicle speed, and tread depth.

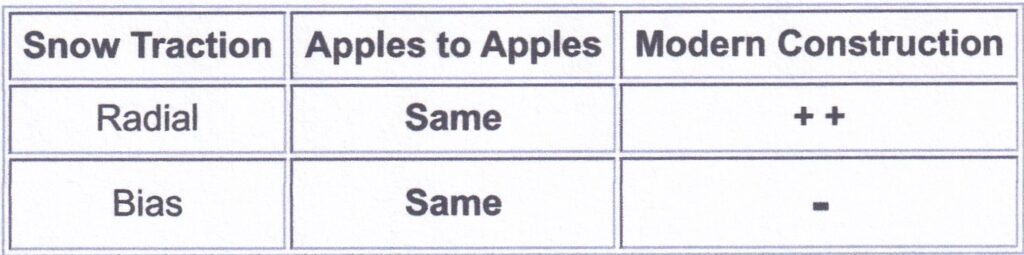

Snow Traction:

This property is mostly about the tread pattern – and as such isn’t different between construction types.

EXCEPT

The belt in radial tires allows for a more aggressive tread pattern with the loss of treadwear still being better than a bias tire. This is done by careful selection of the tread rubber compound.

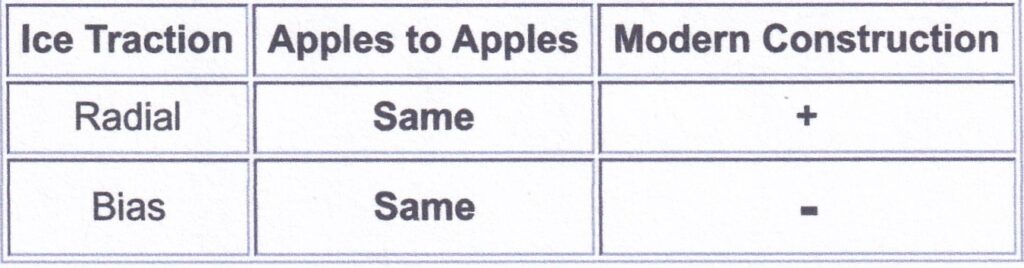

Ice Traction:

This is mostly about the tread rubber compound – and just like snow traction isn’t different between constructions

BUT

just like snow traction, the belt allows for the tread compound to work better

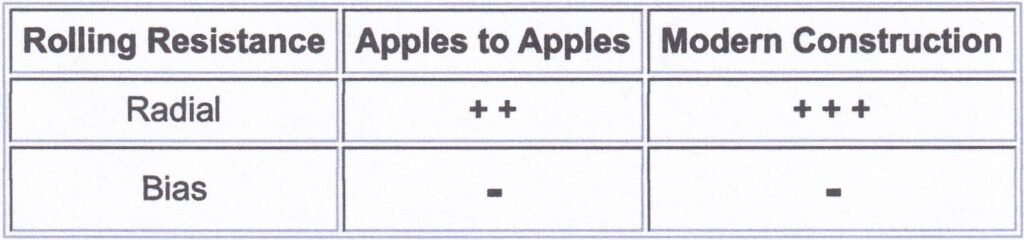

Rolling Resistance:

Another place where radials greatly exceed bias ply tires. Rolling resistance is the biggest reason radials got adopted so quickly – because of the 1973 OPEC oil embargo. (Goggle it for more information.)

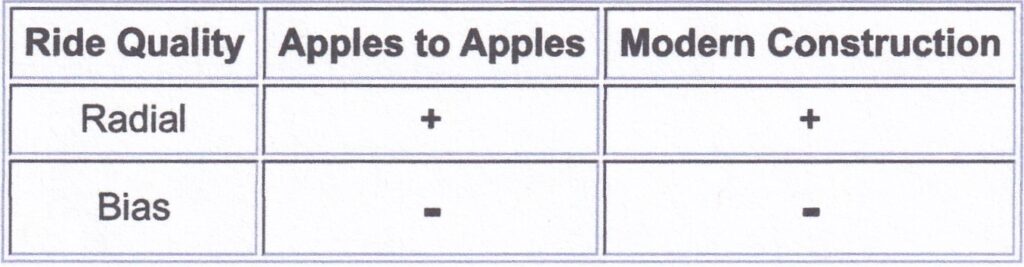

Ride Quality:

Here it’s the radial plies that help. The crisscross bias plies in the sidewall stiffen the sidewall.

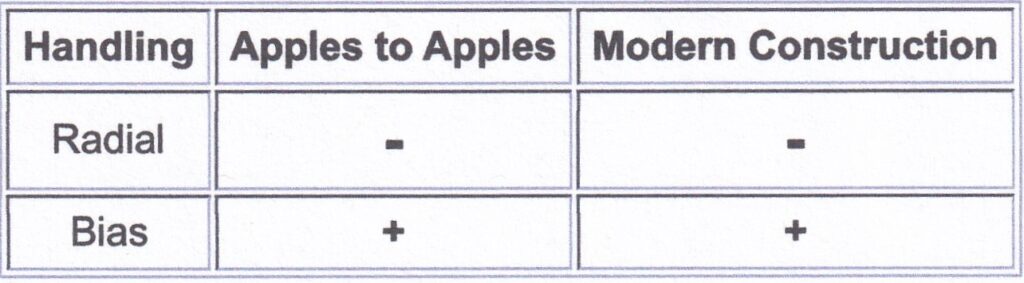

Handling:

This is how the car feels and how quickly the tire responds to steering input – and the bias tire with its stiff sidewalls does this better.

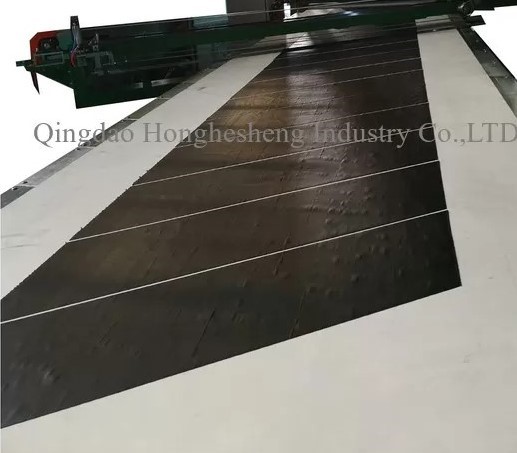

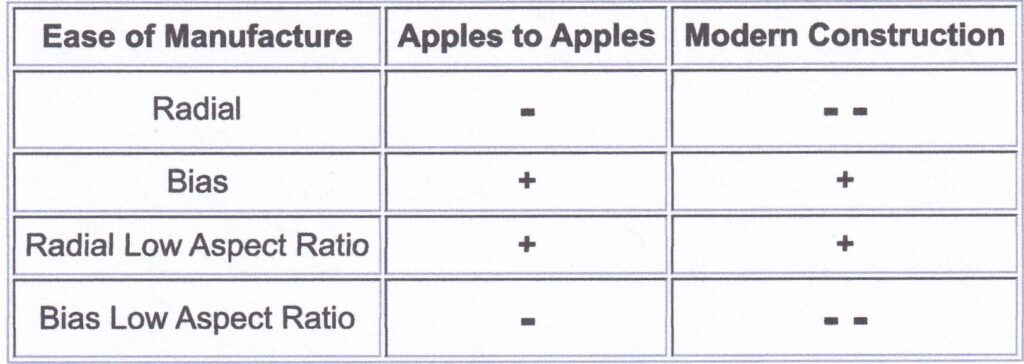

Ease of Manufacture:

Radials require additional equipment. Some of that equipment is for building and applying the steel belts to the partially completed casing, while some of that equipment is part of the mold. The belt doesn’t like being stretched, so it has to be applied separately from the body plies, and the mold is segmented so the tread pattern moves INTO the tread rubber.

The photo to the right shows a segmented mold laid out to show the segments and the bottom bead/sidewall ring.

There’s one peculiar thing about manufacturing bias ply tires – and it’s that because the ply material is cut at an angle, there is a limit on how high of an angle can be cut and how wide of things the building machine can accommodate.

What that means is that bias ply tires are extremely difficult to make with low aspect ratios.

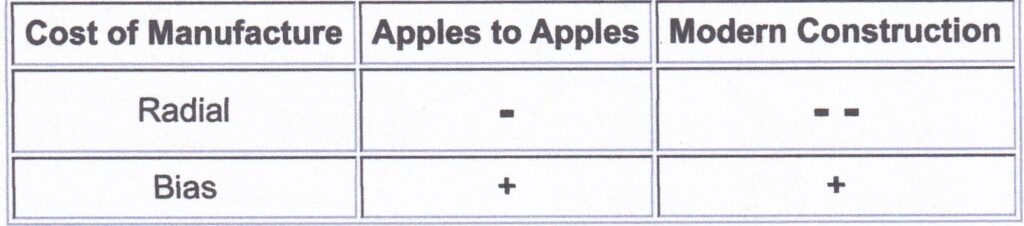

Cost to Manufacture:

In addition to the extra equipment, the materials used in a radial tire have to perform at a higher level.

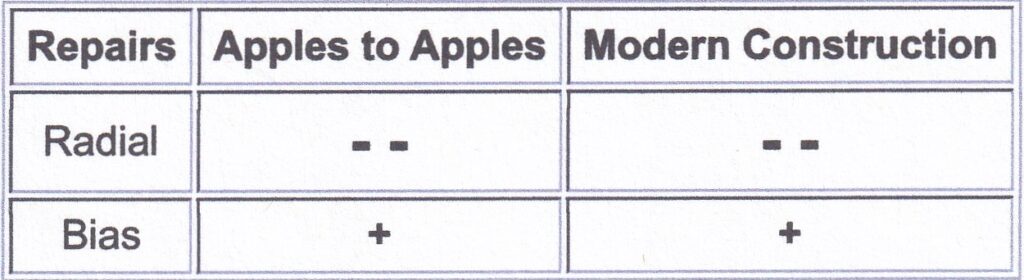

Repairs:

Bias ply tires are fairly tolerant of repairs – both plugs and patches.

By contrast, radial tires have 2 areas where repairs don’t work as well as they should – the edge of the top belt and the entire sidewall.

The edge of the belt is where the highest stress is. Repairs in that area could cause a separation – very dangerous.

The sidewall in a radial tire goes through a very complex movement as the tire rolls through the contact patch. Bias tires spread that same movement over a larger area.

Further, plugs sometimes don’t seal at the outside surface, so it’s possible for water to find its way to the steel

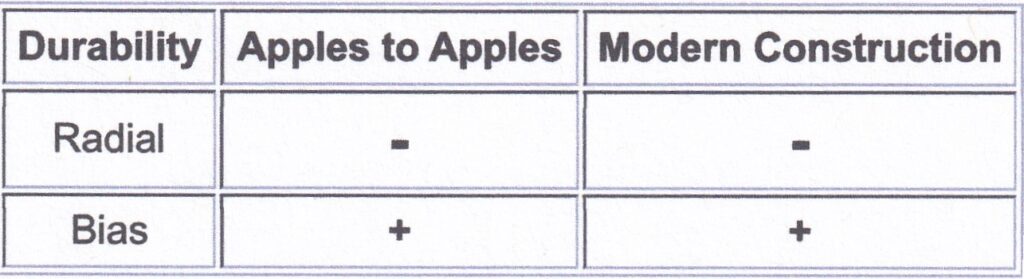

Durability:

This is how susceptible the tire is to a structural failure. The good news is that radial tires have improved so much, that there is only a slight advantage for bias tires.

When we tire engineers use the term “durability”, we never mean wear resistance.

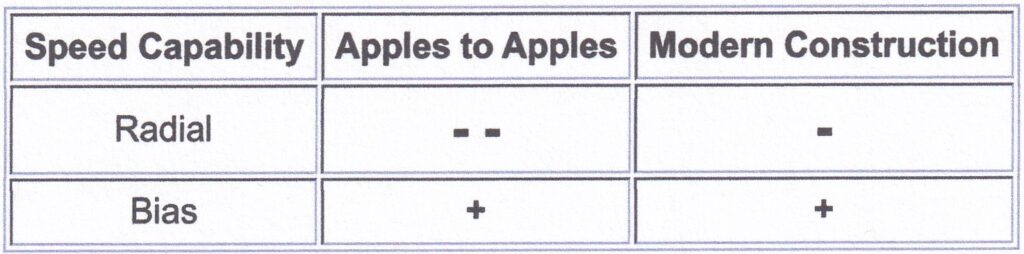

Speed Capability:

While radials can be made with very high speed capability, it requires cap plies (the higher the speed, the more cap plies). It’s the belt trying to be thrown off by the centrifugal forces. I am not doing that comparison!

By contrast, a bias tire, while affected by those same centrifugal forces, resists a bit better because they don’t have that additional mass.

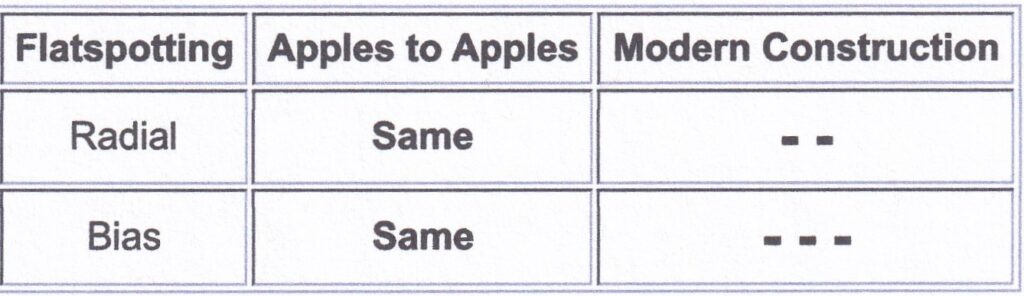

Flatspotting:

Modern bias ply tires use nylon – and nylon is prone to flatspotting. That’s because nylon has a glass transition temperature in the operating temperature range of a tire, so when the tire cools down after operating, it takes the shape it is in – with a flat spot at the contact patch.

Modern radial tires only use nylon for cap plies, so they are also prone to flatspotting, but since they use less of it, the effect is smaller.

The good news is that unless the tire sits for a long time, nylon flatspotting is temporary.

In the case of the Apples to Apples Comparison, I’m assuming the same materials, so no nylon involved. In the case of the Modern Construction comparison, I am comparing S rated to S rated.

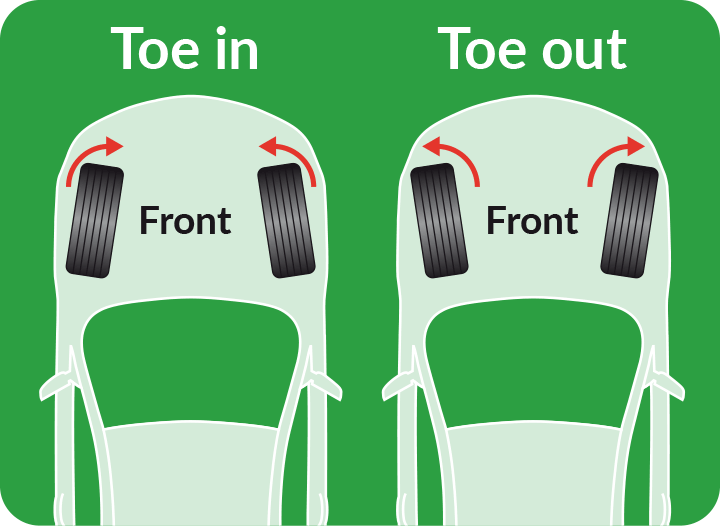

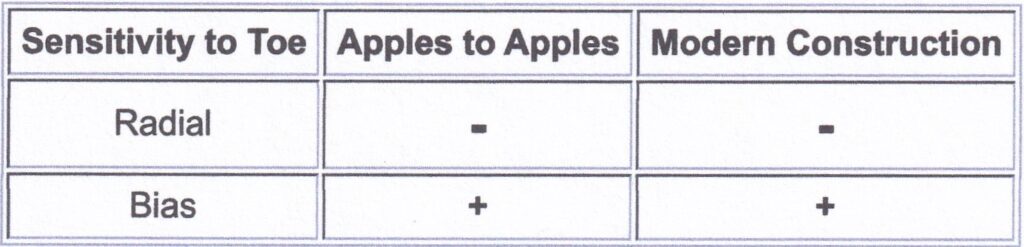

Sensitivity to Toe:

Because of the belt, radial tires are more sensitive to toe than bias tires. Only a few car manufacturers have recognized this and adjusted their alignment tolerances.

On a personal note, I think the toe on a passenger car should be within 0.1º (1/32 of an inch). Please note that the chart below reflects that sensitivity to toe is bad.

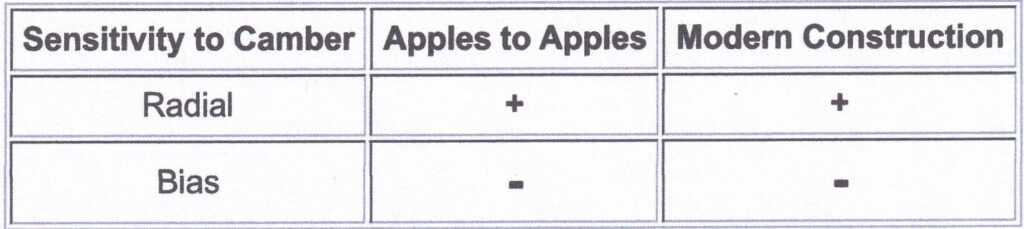

Sensitivity to Camber:

Because of their naturally soft sidewalls, radial tires are not as sensitive to camber as bias tires. Many car manufacturers take advantage of this by aligning their vehicles with a lot of camber.

On a personal note, many car manufacturers overdo the camber and it causes one sided wear especially if there is excessive toe. I think anything over 1º is excessive for wear purposes.

Summary Please note that this chart is organized differently than the charts above AND a positive sign means better for performance. This is particularly important in the last 2 entries, as sensitivity to alignment is a bad thing. Also, if there is no difference between radials and bias, I’ve used “same” in both columns. |