TRX Tires

By the late 1970’s, the transition from bias ply tires to radials was more or less complete. The typical aspect ratios were 80, 78, and 75, with 70 series considered low profile. It was known that the lower the aspect ratio, the better the handling, but the worse the ride. The TRX was developed to address this issue.

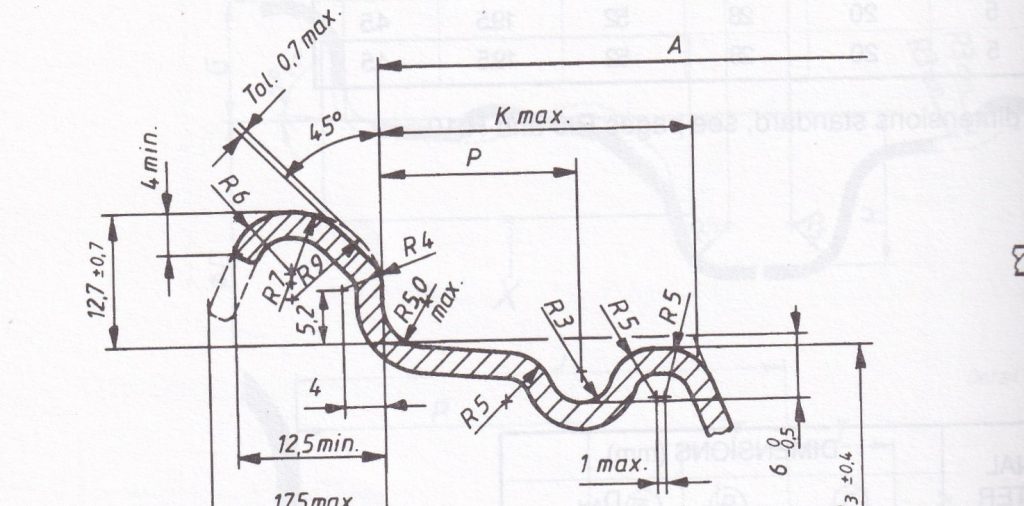

Michelin developed a tire/wheel combination that had an angled and lower height flange that increased the amount of the sidewall flexing, resulting in a better ride. Because of the different flange, Michelin designed the wheel to come in metric diameters. That way it would be obvious which tires were designed for that special flange.

Ya’ see, it was common for tires to be sized in inches for both width and rim diameter. When radials came onto the market, it was the Europeans who led the way – and they decided to use metric units – except that wheel diameters in inches were carried over – I suppose so that the transition would be easier.

So the first radials were sized like this: 205R15 – a mix of metric and English units. Even lower aspect ratios were a mix, like this: 185/70R13. This has been carried over to the present day.

The only thing special about TRX tires/wheels was the flange. It was shorter and angled. (See the 2 images to the right, the TRX on the top.) This allowed more flexing of the sidewall and resulted in a better ride.

The sizing convention at the time (and still today!) was width/aspect ratio, bias ply/radial, rim diameter. Like this 205/70R15. Because TRX tires had a different flange configuration, these were specified as all metric – like this:

205/70R340

The wheel diameters were standardized at 340mm (13.39″), 365mm (14.37″), 390mm (15.35″), and 415mm (16.34″).

I think it is obvious that when the car manufacturers sourced these TRX tire/wheels, that the first sources for tires was Michelin. It took a while, because of the development costs, but other tire manufacturers did eventually produce appropriately sized tires. But it didn’t last very long.

Today, the only source of these tires is Michelin – in their vintage series.

But as these things go, shock absorber manufacturers figured out ways to soften the ride without making the handling too sloppy, so the TRX innovation became redundant.

By 1985, the thing had run its course. It lasted 6 or 7 years, depending on how you want to measure it. Looking back, it should have been obvious that the answer to the ride problem was reducing the size of the forces being transmitted to the chassis, not reducing the forces being generated as there is a limit to how small the forces could be generated, but no limit as to how much of those forces could be prevented from being transmitted to the chassis.

PAX Tires

For as long as I can remember, car manufacturers wanted to eliminate the spare tire. Not only would that save weight, but the jack and related handling equipment would no longer be needed.

A number of solutions were tried, mostly just reducing the weight and size of the spare itself. Every one of these has shortcomings.

Among those ideas was the use of a wheel within the tire, slightly smaller in diameter than the inflated tire, which would come into play if the tire lost air pressure. Lots of technical issues with that idea.

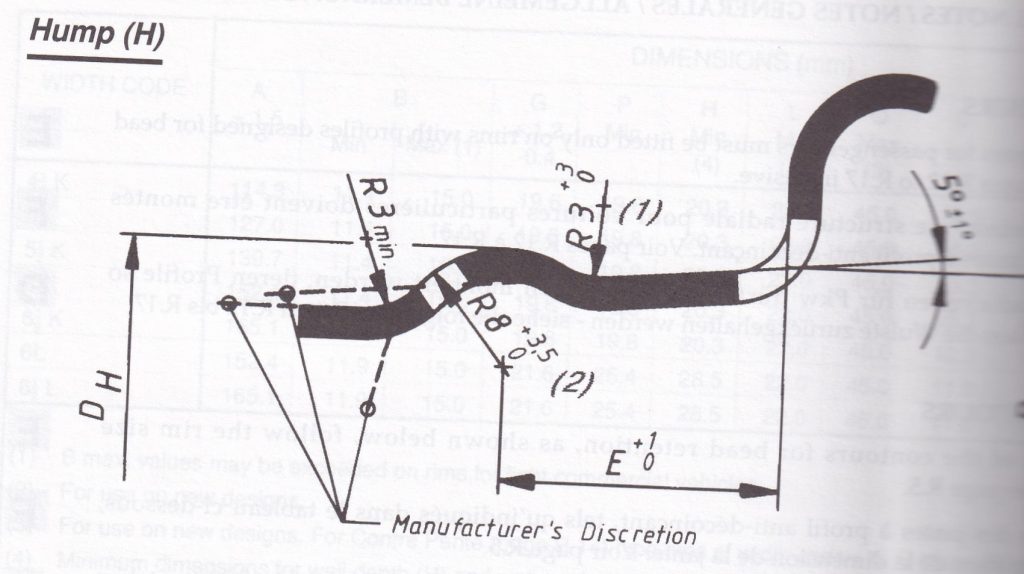

But, WAIT!! Michelin had a better idea. (See the photo to the left) Their idea was to create a special wheel that made it easier to mount that special inner wheel.

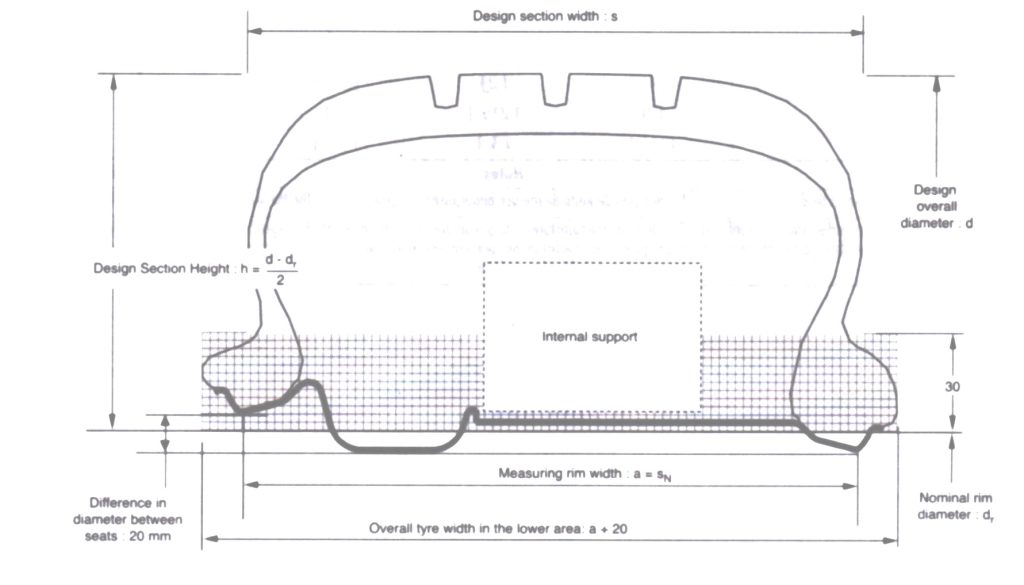

The problem was that not only did the tire still need to be mounted on that special wheel, so part of that wheel needed to be a smaller diameter, but to prevent the regular tire from coming off the wheel, the flange was completely different. In regular wheels, there is what we call that the drop center. But since the inner wheel was where the drop center normally was, the drop center on a PAX wheel was very close to the bead seat.

Overall, that required special equipment to handle mounting the inner wheel and the tire – and that required special training.

The PAX system featured a special wheel with an inner support ring, slightly smaller than the inflated tire’s diameter, to allow driving on a flat tire. This required a unique wheel design and tire mounting process.

Further, even the tire was different. There were 2 different bead seat diameters. So to prevent a mixup, the tire sizing was specially labeled like this:

245-680R460A

Where:

- 245 = width in mm

- 680 = overall tire diameter in mm

- R = radial

- 460 = inner wheel diameter in mm (outer wheel diameter was 40mm larger)

- A = asymmetrical

That means the tire could only go on the wheel a certain way.

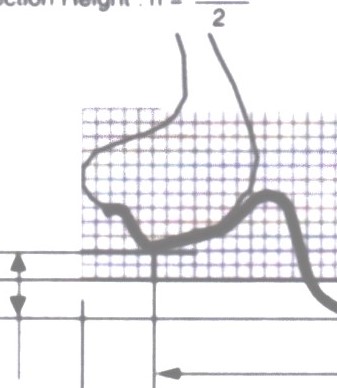

PLUS notice the lower image. That’s the bead area. It’s got this huge bulge, very different than anything I’ve never seen. I suspect that is a flange protector. But it appears to be vital to the wheel/tire fit.

Introduced in 1997, the PAX system was adopted by manufacturers like Honda (on the Odyssey) and Nissan (on the Quest) in the mid-2000s, primarily for special-edition minivans. However, the system’s unique requirements posed challenges:

- Specialized Equipment: Standard tire shops lacked the equipment and training to service PAX tires, forcing owners to rely on dealerships for maintenance, including flat repairs.

- Limited Availability: The system’s complexity and incompatibility with conventional tire/wheel setups meant that the tires had to be special ordered – which took time..

After approximately four years, Honda and Nissan discontinued the PAX system due to its impracticality and the burden it placed on owners and service providers.

Editorial Comment

Both TRX and PAX systems introduced innovative tire and wheel designs but faced challenges due to their incompatibility with standard systems. While TRX became redundant due to advancements in suspension technology, PAX’s complexity and reliance on specialized equipment limited its viability, making it a short-lived experiment in tire innovation.