|

B

arry's

T

ire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Vehicle Drift and Pulls and Tire Conicity: What you should get from this page:

|

|

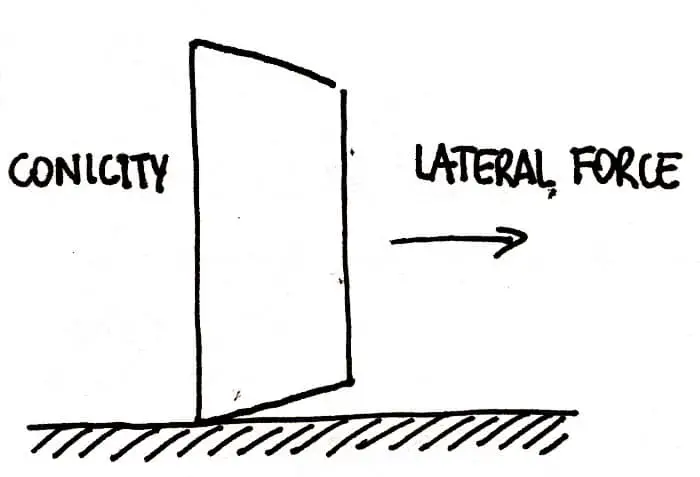

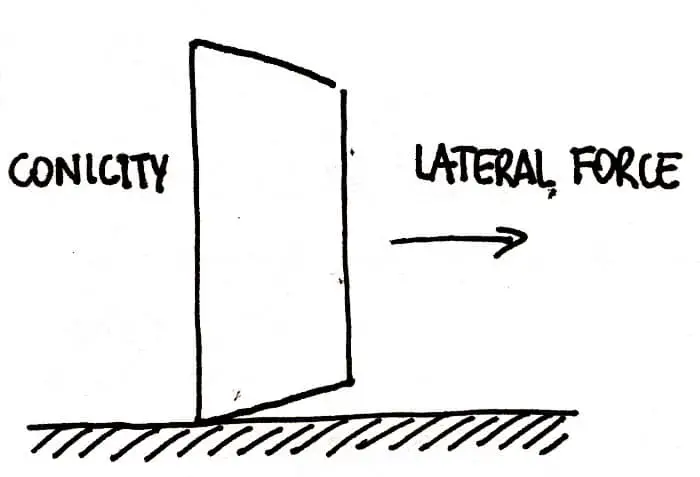

Tire Conicity: The root word is "cone". It's a tire property where the tire is exerting a sideways force when rolling. The force can be pointed inwards towards the vehicle (negative) or outwards, away from the vehicle (positive) - and of course, zero! This can only be measured when the tire is loaded and is usually expressed as a force (pounds or newtons). Tire manufacturers use a TUG (Tire Uniformity Grader) machine to measure conicity. This happens while the machine is also measuring uniformity (Uniformity is discussed here!). It can also be measured at a tire dealership by using a Hunter RoadForce Machine or something similar. |

|

|

The problem is NOT excessively high values! What causes a tire related drift or pull is the vector sum of BOTH front tires: So if both front tires are high in the same direction, there is no pull. Same with 2 low values (provided they are the same direction!) But if the front tires are High/Low, or even 2 lows in opposite directions, you could get a drift/pull. So it is possible to fix a drift/pull by simply swapping tires around until you get a combination such that both tires on a given axle are close in value. While this isn't usually a problem, some vehicles are somewhat sensitive to conicity. Just be aware that your vehicle might be one of those. |

|

HOWEVER! For practical purposes, conicity can not be corrected. So either the tires have to be properly paired, or the offending tire has to be replaced. Please note: A drift or a pull does not cause damage to the car unless it's the alignment that is the problem. A misalignment can cause a tire to wear quickly and/or unevenly, resulting in a high conicity value. That is usually the case where the drift/pull disappears when you swap front tires. Tire manufacturers are aware of the conicity problem. It can be somewhat difficult to fix, so many tire manufacturers are careful to sort tires into positive and negative stacks before they go into the warehouse, and only ship tires of the same direction to a given dealership. |

|

|

So what causes conicitiy? Belt Centering This is the one most commonly pointed out. Given how tires are made, it is somewhat understandable that improvements in consistency in manufacturing - especially new machinery - would improve conicity. |

|

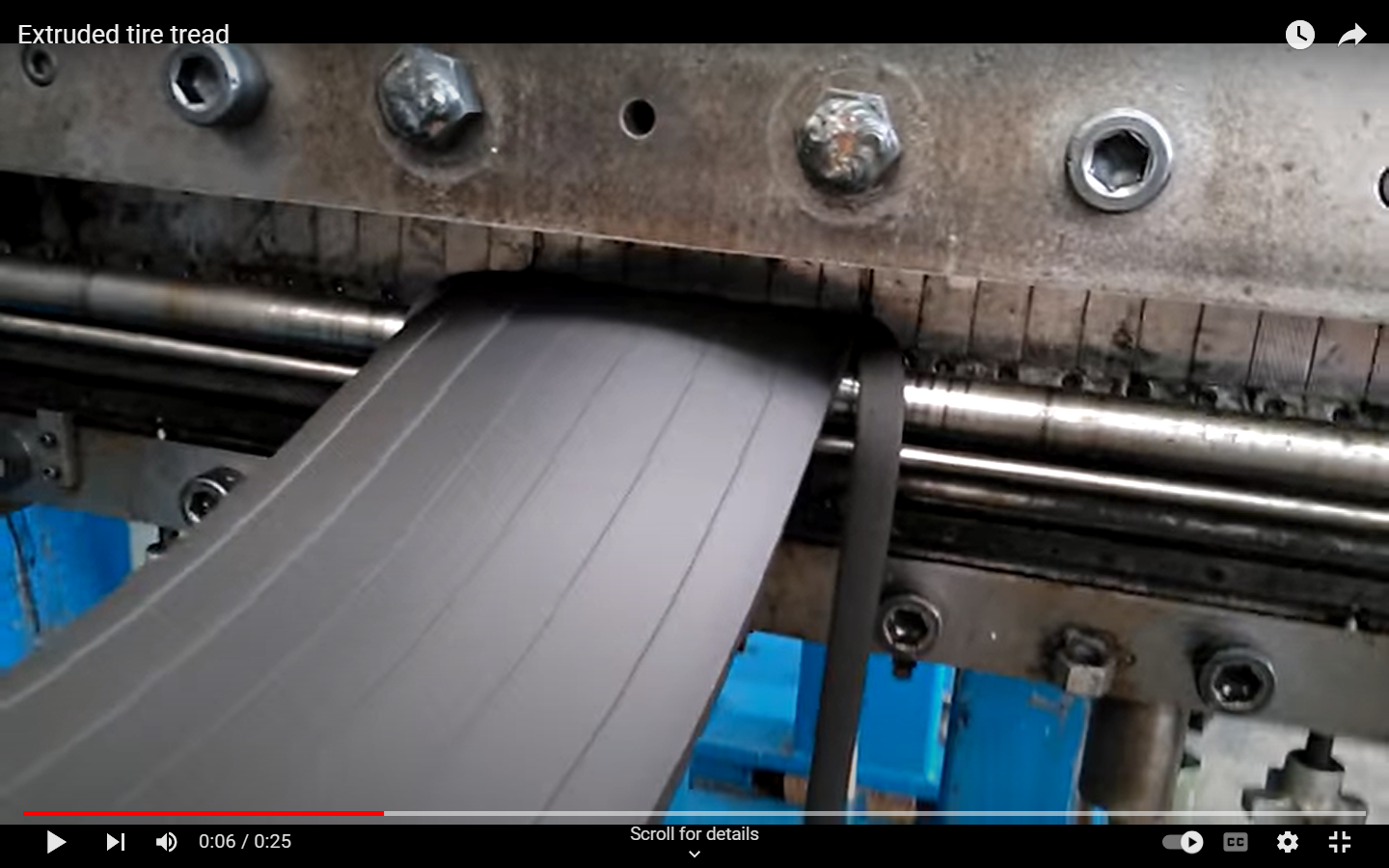

Variations in tread rubber distribution in manufacturing: Remember the image at the top of the page? (and to the Right - the top one!) Well, if the tread rubber applied on top of the belt isn't even side to side, that will cause the tire to be slightly conical. That's because the inflated tire tries to even out all the stresses and that means making the belt the same side to side (assuming the belt is properly centered.) It only takes a small difference. To the lower right is a photo of the business end of a rubber extruder. This type of machine is commonly used for extruding the tread rubber - and I hope it is obvious that getting the die opening even side to side may be a bit difficult. There are other ways of making the tread - and each way has its advantages and disadvantages. And that's where designing new equipment comes in. That also means that it is possible to wear conicity into a tire. In fact, it used to be somewhat common to grind the tread of a new tire in such a way to get smaller conicity values. That same principle would apply to wear. (They don't grind tires much nowadays!) |

|

|

Barry's Tire Tech - Main Page |