|

B arry's

Tire

Tech

This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Tire Traction & Traction Testing - Dry: |

|

This article is about dry traction testing. Read this one BEFORE reading the article on Wet Traction here I address snow and ice traction testing here as part of the article on Winter and All Weather tires. The photo above is of a traction trailer and its tow vehicle. Below I will discuss how tires get tested for traction and that trailer is a key part of how that happens.

|

|

Some History: Much of what we tire guys do with traction testing comes from General Motors. Ya' see, GM used to be a HUGE!! company with lots of resources. In fact by 1970, they had 60% of the US market. Yes, you read that right. 60%! It could be argued that one of the reasons they had that much market share was because of all the research they did. They knew more about vehicles and their component parts than anyone - including the suppliers of those parts. It could also be argued that their market share (and the amount of money they made) allowed them to do all that research. Either way, the early days of tire traction testing came basically from GM. And just to fill in the rest of the picture, today (June, 2022) GM's US market share is 17%. |

|

|

|

|

My involvement with tires started in 1971. About that time, radial tires started being introduced and it was quickly learned that not only did radial tires behave differently than bias ply tires, they also had greatly enhanced traction. That increase in traction allowed tire designers to get more aggressive with the tread patterns to enhance wet and snow traction. To the left is the old SRTT (Standard Reference Test Tire). It used to be called the Standard Reference Traction Tire, but when they started using it for other tests, they changed the name. Notice it has a TPC number (1024MS). That means it was an approved General Motors tire with approval number 1024 of the all season variety. For those who wonder about such things, GM started assigning TPC numbers with the number 1001. That means this tire is the 24th tire assigned a number. GM is currently over 2300! |

|

SRTT's are used in tire traction testing because traction can vary by testing surface, weather, temperature, etc. In order to compare the results of tests performed at different times and in different places, the test results have to be adjusted based on the results of the SRTT. Because the SRTT has been used so frequently, there is a good amount of data that can be used to determine if an individual test is being run correctly and the results are reliable. In other words, if the value received for the SRTT is the same as before (or as expected based on the test surface, weather, etc.), the data can be used with confidence. If the value is DIFFERENT, something is wrong and the source of that difference needs to be tracked down and corrected. Remember I said that GM was heavily involved in early days of tire traction testing? The proof is the TPC number on the SRTT. THEY decided what the SRTT was going to be! And what they decided was a Uniroyal branded tire - a P195/75R14. And for context, this happened before Uniroyal merged with Goodrich - and long before Michelin bought the merged company. |

|

|

To the right is the latest SRTT - also a Uniroyal branded tire, but in a P225/60R16. And notice there is no TPC number.

Why the change? SRTT's are tires that have been certified during manufacturing - both rubber compounds and the construction technique. The old SRTT had rubber compounds and construction techniques developed in the 1960's. Some of the chemicals and processing equipment is no longer available, so a more up-to-date tire was chosen. |

|

|

And here's what the tread pattern of the new SRTT looks like. The use of the SRTT has expanded a whole lot since the first one. It is now used for all kinds of testing where a tire of known and consistent properties is desired. For example, the SRTT is being proposed for rolling resistance testing to adjust values of tires tested at different testing facilities. |

|

Dry Traction Testing:

Before the test starts, the tire (new) is cleaned off, by applying the brake on the trailer in a process called "chirping" - because that's the sound the tire makes. That removes any mold release compounds that might have been used in the manufacturing process. The test consists of the tow vehicle getting up to speed on the test course, then the brake on the trailer is increasingly applied passed the point where the tire reaches maximum grip and into where the tire reaches a steady sliding value. This only takes a few seconds. Both the peak value and the sliding value are recorded. This is repeated many times (usually 10 times). Then the data is analyzed for consistency using a statistical test. If the data is consistent, the test is over for that tire and they move onto the next tire. If the data is not consistent, the test is repeated. Some time in the whole series of tests will be a round with the SRTT. |

|

|

Test Surfaces:

Not only does the traction coefficient vary with the surface, but there can be reversals. This is a real problem that even the use the SRTT doesn't solve - and that was not known until well after the SRTT was in common use. Did you notice I didn't use the word friction? That's because tires don't behave according to classical friction theory (aka Amonton's 3 Laws) That's Guillaume Amonton to the right. Technically, those laws were discovered by Leonardo da Vinci in 1493, but he never published them. Amonton rediscovered them in 1699. They were verified by Charles-Augustin de Coulomb in 1781 and you will hear Coulomb's name associated with those laws. |

|

|

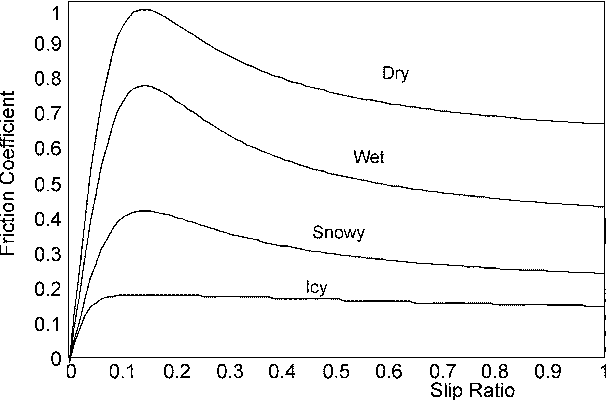

What tires do is penetrate the macrotexture of the road surface and additional grip is obtained. Max grip usually occurs at 15% slip.

The graph to the left illustrates how this works. For dry, wet, and snowy surfaces, the tire penetrates the road surface just a bit so that more than just friction is taking place. It's only ice where this falls apart - mainly because the tire doesn't penetrate the icy surface and therefore behaves much more like classical friction theory. Note: The graph to the left is an idealized graph - that is, not a graph of actual data. I think the snow and ice lines show too much performance on snow and ice. |

|

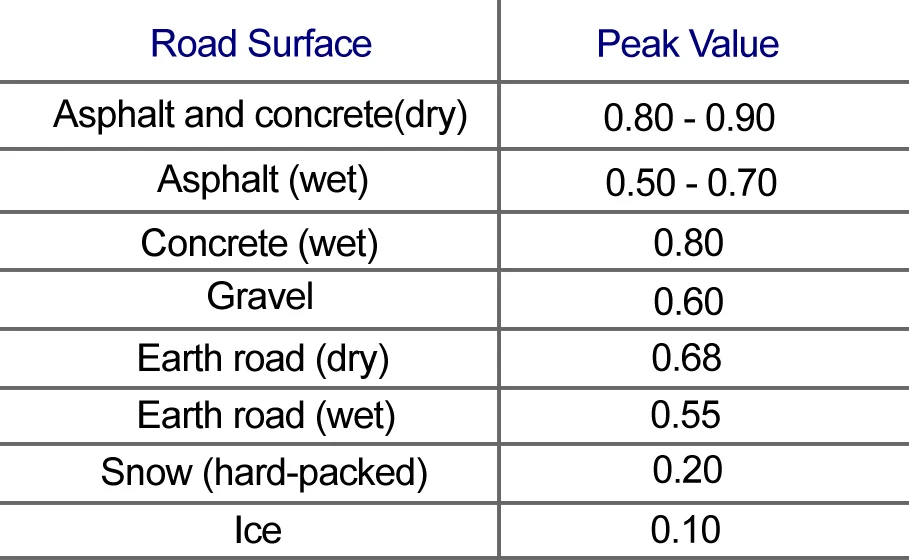

The chart to the right shows some values for various surfaces and - indeed - snow and ice traction values are lower than the above graph. |

|

|

Here is where it gets complicated. Obligatory: I am NOT a rubber chemist, but I have worked alongside some very talented individuals and have learned a lot from them. This is my own way of looking at this. Yes, I know it is technically incorrect, but it has helped me visualize this and perhaps it will help the reader, too. I divide tire traction into 2 parts:

The image to the right illustrates this. Please excuse the quality of the drawing. I am not an artist. Notice the bits of rubber being peeled off by the stones. |

|

What this means is that some rubber compounds have a high amount of friction compared to grip, but others the reverse is true. So depending on the pavement, the overall grip of the tread compound might be dominated by friction or by grip. That also means that if you test a number of different tires, the rank order won't always be the same. There will be reversals. Further, the adage that wider tires get more grip (all other things being equal) would obviously be true. Where this gets really technical is that all things CAN'T be equal - Because when you go wider and don't change the aspect ratio, the load carrying capacity goes up. - AND - when you go wider AND try to keep the same load carrying capacity, you have to change the aspect ratio. In the photo to the right, notice the small bits a rubber on the road surface. Racers call that "marbles" or clag. Those bits of rubber are from the tearing of the tread surface and they accumulate just off the racing line. They interfere with the tire reaching the road surface so that area is slippery. Plus, they are sticky! That's why you will see racecars weaving back and forth before returning to racing. They are trying to remove all those bits between the tire and the road surface. |

|

|

And when we add water, the problem gets even worse. Wet traction has the additional component of hydroplaning - which is EXTREMELY dependent on speed - which is one of the reasons why traction testing is frequently done at the same speed as dry traction - 40 mph. At that speed, the effect of hydroplaning is felt, but full hydroplaning doesn't take place (unless the water is too deep). Does that mean that dry traction testing takes place at 40 mph because of wet traction testing? I think it does! Put another way, once hydroplaning occurs, you basically don't have any traction. So if you want meaningful wet traction results, you have to test below the hydroplaning speed, so that the tire is only partially hydroplaning. |

|

At this point I would have liked to show you some useful data - like dry traction vs wear - but I couldn't find any. I suspect that is because dry traction doesn't vary much with wear (until you wear into the steel belt), plus there is an abundance of traction in the dry. Not so much for wet traction. I should also point out that while tire manufacturers have the wherewithal to generate some useful information, these tests cost money and time. Unless there is a competitive reason to do something, they tend not to do it. I ran into this several times in my career.

|

|

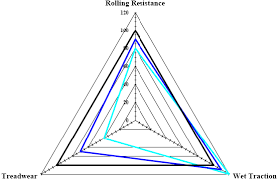

And lastly, traction can't be talked about without mentioning the tread rubber compound. Unfortunately, I am not a rubber chemist. I just don't know enough about the subject to talk about it for this article. EXCEPT: There is a 3 way technological triangle involving treadwear, traction (especially wet traction), and rolling resistance. Improvement for one of those involves sacrificing one or both of the others. EXCEPT: From time to time, those same talented rubber chemists will come up with a new ingredient or a new manufacturing technique that will change the basic triangular relationship slightly. And slightly is the operative word here - That basic relationship still holds. |

|

|

Here's a link to the next part of traction testing - wet traction: |

|

|