|

B arry's

Tire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Tire Traction & Traction Testing - Wet: |

|

This article is about wet traction testing. If you haven't already, it would be better if you read my webpage on dry traction here. This page will make a lot more sense if you do. I address snow and ice traction testing here as part of an article on Winter and All Weather tires |

|

Wet Traction: There are 2 methods: 1) Flood the test surface with water, then conduct the test just like dry traction testing using the Traction Trailer. In this method, there is a pipe pumping water onto the test surface and the output of the pump is throttled to get the right amount of water depth (as called for by the test). The problem with this is that the wet surface takes a while to dry, so it can't be used right away for dry traction. This can present some scheduling difficulties. |

|

2) Discharge water immediately in front of the tire during the test. That is what is shown to the right. The water tank is in the pickup bed. The advantage is that the test surface is only wet right where the test took place and not the entire surface. That means there will only be a portion of the test surface that is wet and the rest of the surface can be used for dry traction. I should point out that dry traction testing destroys the tires, but wet traction testing doesn't, so it would be best if the wet traction tests were done first, and the dry traction test done later. That's why the second method was developed. The tests can be run back to back without changing tires on the trailer. |

|

|

There ought to be a 3rd method involving the weather, but I have never heard of such a procedure. I guess mostly because the test facilities are located in the desert southwest (AZ, TX, etc.) where it doesn't rain much, so you don't really need a plan. You just sit out the day or 2. |

|

And - of course - someone has to do things differently. And in this case, it's the European Union. They require tires to have a grading label and the test for wet traction is a on-vehicle ABS braking test from 80 kph (50 mph) to 5 kph (3 mph). The reason they don't use Zero kph (mph) is because ABS systems do some funny and (importantly) different things below 5 kph. The test uses the SRTT. Water depth = 1.5 mm = 0.059" (1/16" = 0.0625") So just under a 16th of an inch. I am trying to find info on the test surface. |

|

|

Test Surfaces:

They use the same surfaces to test wet traction as they do dry traction - unless the test is strictly a prescribed wet traction test like the UTQG traction test. As with dry traction testing, the traction coefficient varies with the surface, and there can be reversals. Again, the SRTT doesn't solve this problem. Eagle eyed readers will wonder what is going on in the photo to the left. Notice that there is a concrete surface and an asphalt surface and there is enough room for the vehicle to be moved such that the left front could be on either surface. Remember I talked about the EU (European Union) having a different test? This is the test set up for that test The left front is the test position and the rail guides the vehicle such that the test position will be on one surface or the other. The driver doesn't have to steer the vehicle during the test. The test calls for testing on both surfaces - with different requirements for each surface. |

|

Wet traction testing is complex - because wet traction is complex. In addition to dry traction's grip vs friction, there is hydroplaning - which is EXTREMELY sensitive to speed. And, of course, hydroplaning is pretty much the opposite of traction. So the goal is to get the tire to only partially hydroplane. So efforts are made to control the speed of the vehicle, the depth of the water, the load on the tire, inflation pressure, etc. For this reason, the UTQG (Uniform Tire Quality Grading) system tests tires at 40 mph with a locked wheel. Some claim that a locked wheel traction value doesn't apply when there's ABS (Anti-Lock Braking Systems) - and they have a point. The test was developed BEFORE ABS was common and a locked wheel was considered the worst case, hence the test. Personal opinion: The government (NHTSA) needs to look at this. |

|

|

Further, many people claim that the UTQG traction test is really testing the tread rubber compound - and I sort of agree. I agree to the extent that the grooves in a tire do provide a place for the water to go to, but the pumping action of the tread pattern - particularly directional tread patterns - doesn't take place |

|

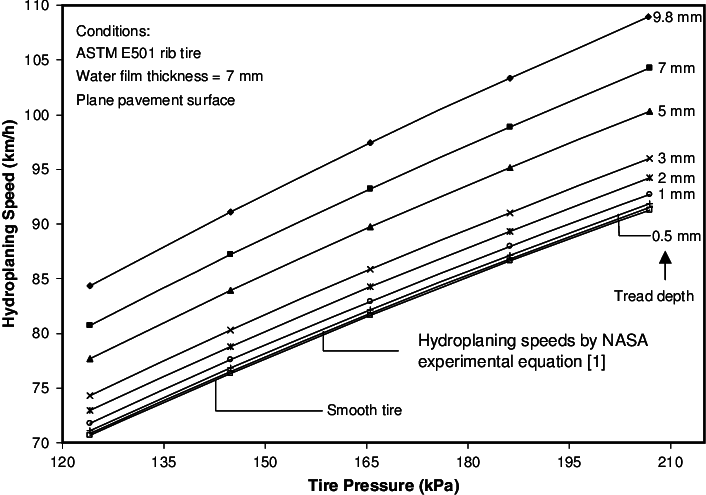

To the left is a very interesting graph of test results for wet traction. First, the graph says: "Hyrdoplaning Speeds by NASA experimental equation (1)". What they are referring to is an old equation developed by NASA in the 1950's: (Hydroplaning Speed in mph) = 10.35 X SQRT(inflation pressure in psi) (for example: 62.1 mph @ 36 psi). This was for aircraft tires. It's also been a long time since that testing was done - and passenger car tires have greatly improved since then. And that graph shows it! Please note that this graph not only shows that hydroplaning speed increases with inflation pressure, but also that more tread depth is consistently better. |

|

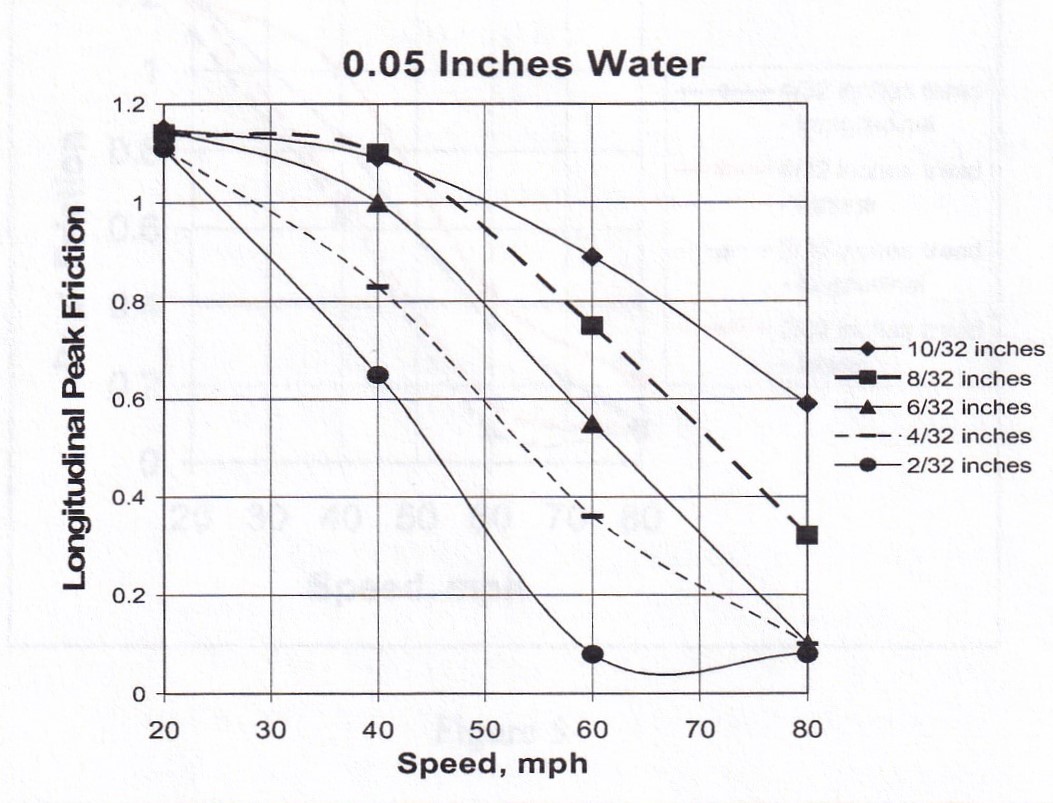

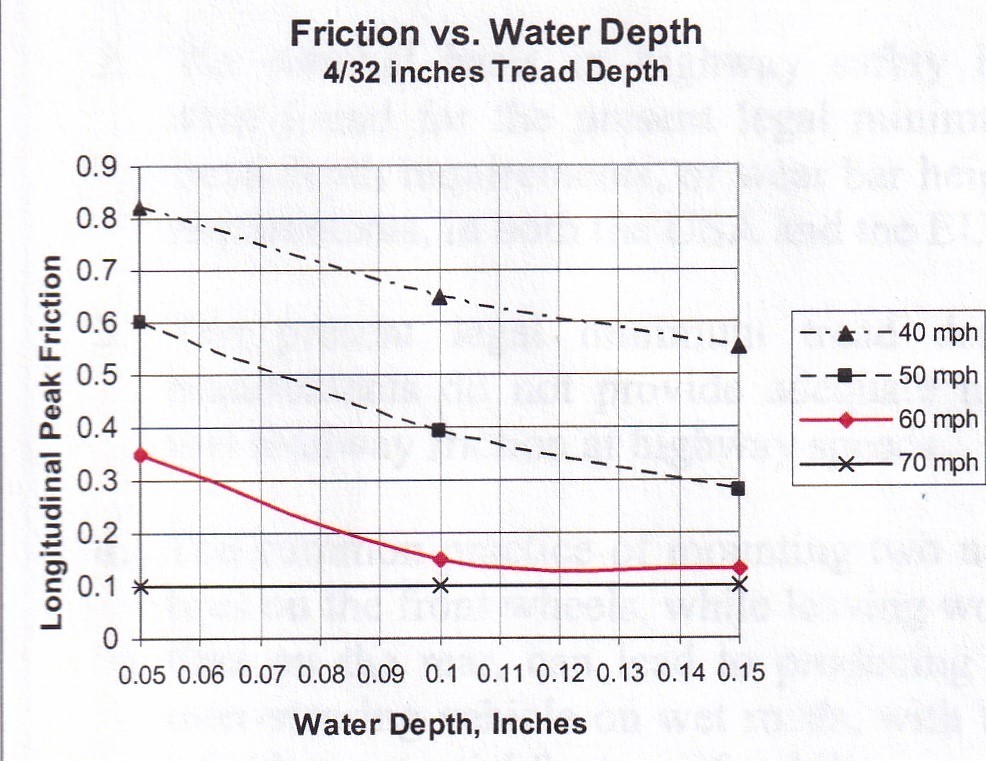

And another one! To the right is a graph from SAE 2002-01-0553 By William Blythe and Terry D. Day, March 2002. It shows the traction of a P215/75R15 Michelin Symmetry at various states of wear. Clearly the tire is hydroplaning above 60 mph at 2/32nds, but notice how much traction is lost from the full depth.Just for an FYI: The EU (European Union) tests tires at 1.5mm water depth (0.059"), which is almost the same as this test. This graph has been cited as evidence that there needs to be a law requiring a minimum NSD (Non-Skid Depth) of 4/32nds (3mm). The Federal regulations for car tires (FVMSS 139) call for a tread depth indicator at 2/32nds for all new tires, but doesn't say anything about it being illegal to operate below that depth. That means it is up to the states to decide what is legal - and it varies all over the map!! (pun intended.) Some states call for 2/32nds, some call for 4/32nds, and some don't have any regulation at all! |

|

|

To the left is another graph from that same paper. It shows the effect water depth has on traction. It is clear that hydroplaning is taking place at very thin water depths for 70 mph, and for a moderate depths (0.1") for 60 mph - and most importantly - at 50 mph, even water depth up to 0.15" did not cause hydroplaning.A Word of Caution: This test was conducted with one particular make/model tire. The results of other Brands/Models/States of Wear will be different and perhaps greatly different. Do not take that graph to mean that one can travel at 50 mph and be safe from hydroplaning. |

|

If you want to find out about snow and ice traction testing, the following page has that:

|

|

Update Jan 2024: I stumbled across an article from Consumer Reports that says that All Season tires lose 8% of their hydroplaning resistance and 7% of their wet braking when half worn: Consumer Reports: Make Sure Your Tires Have Enough Tread for a Snowy Winter That's less than the graphs above! |

|

|