|

B arry's

Tire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

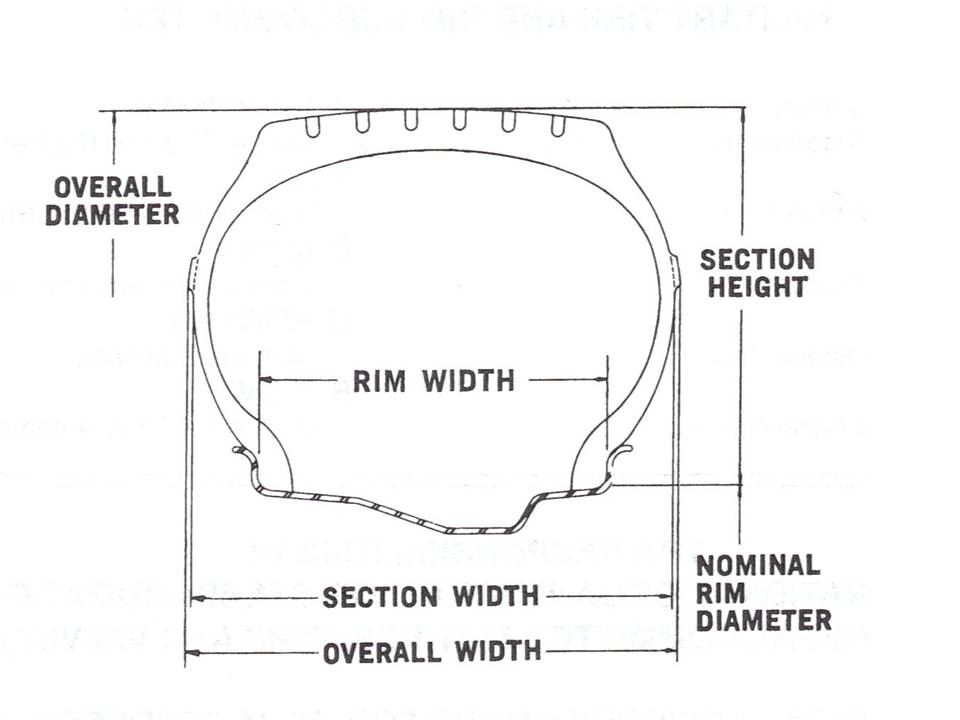

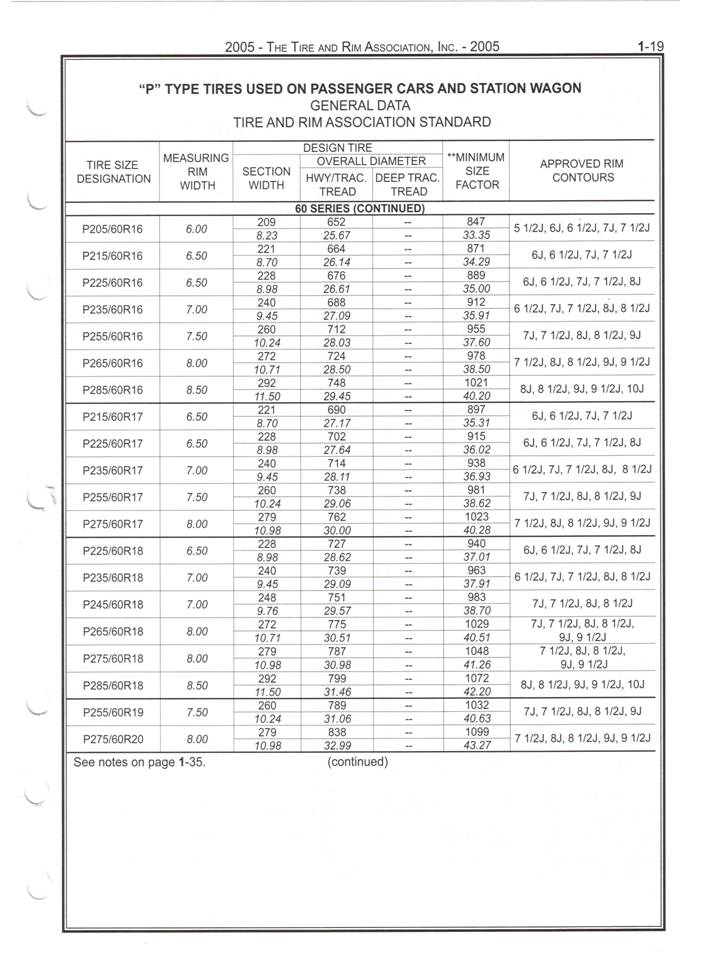

Tire Dimensions: If you haven't read up on Tire Standardizing Organizations, I suggest you do so. It will help you understand this page better: Barry's Tire Tech - Tire Standardizing Organizations Also, Tire Rack has done such a good job of explaining tire sizing that I doubt I could do better (not to mention how much work it is to make a new web page!). Please read it and if you want more detail, come back to this page. Tire Rack's web page on Tire SizingHere's a scan of one of the pages from the 2005 TRA Yearbook. |

|

Notice that the dimensions are in both SI units (mm) and English units (inches), however, there differences in the 2 dimensions isn't worth talking about. This is one area where all the tire standardizing organizations are in complete agreement.

2 things:

|

Occasionally a vehicle manufacturer will have a space problem and need to have a tire that is smaller in one or more dimensions. It's the European car manufacturers who seem to be the biggest perpetrators, and because their regulations regarding what is allowed to be installed are so restricted, they can pretty much have that approved. This presents problems for other tire manufacturers who are building tires to the standard dimensions. Experienced tire guys are familiar with:

|

|

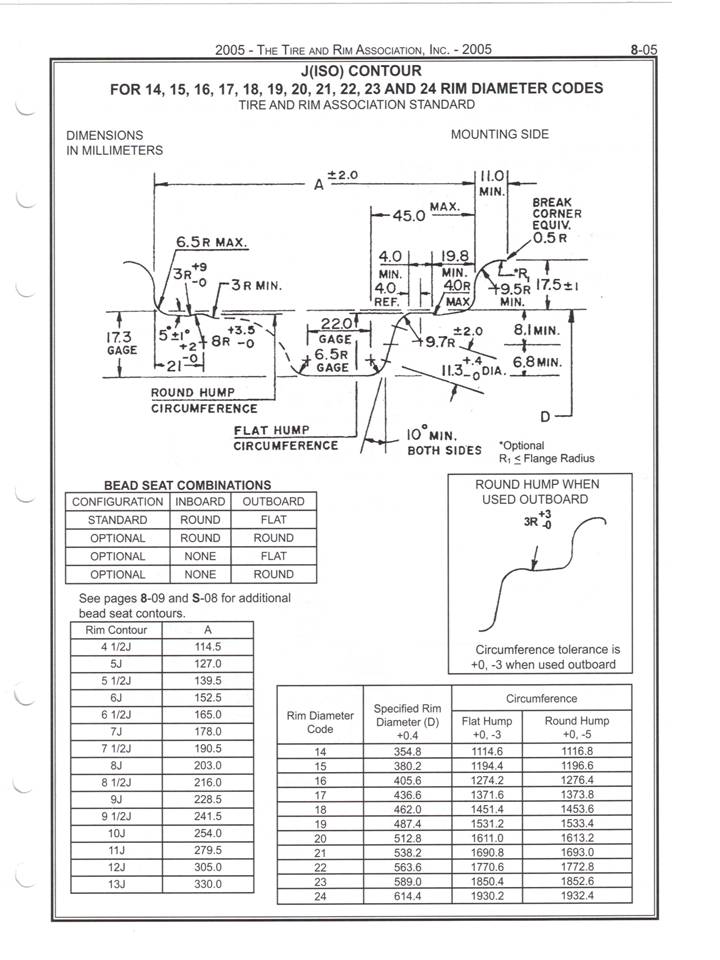

I mentioned before that the mating surface between the tire and the rim - basically what is designated on this page is 100% specified for the rim and nothing is specified for the tire. But notice that the contour of the rim is indicated as a "J" flange. There are other pages that define other contours. This is something the vast majority of people don't have to worry as flange contours are generally grouped by type of tire - meaning type of service - so all tires used in passenger car service - for example - only have to fit certain rim flanges - and rims designed for certain types of tires can only have a certain group of rim flanges. When it comes to tire standardizing, this is one area where all the tire standardizing organizations have done a good job. All the dimensions are the same, no matter which organization's yearbook you look at. |

|

One last thing before we leave this subject.

There are quite a few "Tire Calculators" on the web. Here's one:

www.1010tires.com - Tire Calculator

I don't know of any of these calculators that refer back to the dimension tables in any of the yearbooks. Every one I looked at used the "dimensions" in the size and - for practical purposes - they get pretty close to the Overall Diameter listed in the yearbook. More importantly, when they compare tire diameters, the error is not worth mentioning.

BUT, every calculator I have looked at has a flaw!!!! They assume the overall diameter is the same as the rolling diameter AND THIS IS NOT TRUE!!! The rolling diameter is about 3% smaller than the overall (unloaded) diameter. No, it's not the same as the loaded diameter (or better specified as the "Static Loaded Radius". This is because the tire is not only "squished" at the bottom, but it "hangs" from the top. ("Squished" "Hangs" Surely there are some sweet sounding technical terms that cover them, right? I wonder what they are?) So it's better to think of "rolling circumference". This way it's easy to understand that the belt seems to act like a tank track with the tread rubber on top of the "links" - and it is the distance between each link times the number of links, that determines the "circumference". What this means is that so long as the calculator is doing comparisons, the "3% problem" isn't a problem. But if they start calculating Revs per mile or gear ratios, there's a built in 3% error - except for this tire calculator!!! Kudos, 1010Tires!! (Full Disclosure: These guys talked to me when they were revising their web site.) (OK, nit pick time!! They still didn't get the width right. It should read "Section Width", not "Tread Width") |

|

Barry's Tire Tech - Load Tables Barry's Tire Tech - Dimension Tables |